Surface soil compacting roller with bionic geometric structure

A technology of geometric structure and pressure roller, applied in the field of soil pressure roller and agricultural machinery tillage parts, can solve the problems of increasing soil disturbance and damage, generating clods, reducing work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

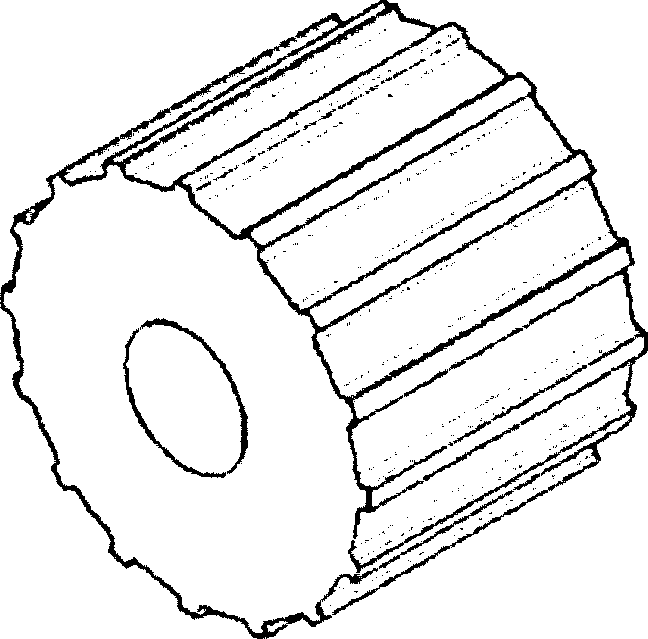

[0051]Referring to Fig. 1(a), the surface soil suppression roller with bionic geometric structure has a geometric structure of continuous ribs distributed along the roller alignment. The rib height is 5mm-50mm, the width is 10mm-50mm, and the rib spacing is 0mm-50mm; Carbon steel material, bionic geometry adopts ultra-high molecular weight polyethylene material or enamel coating material; grooves are dug out on the surface of the pressure roller base.

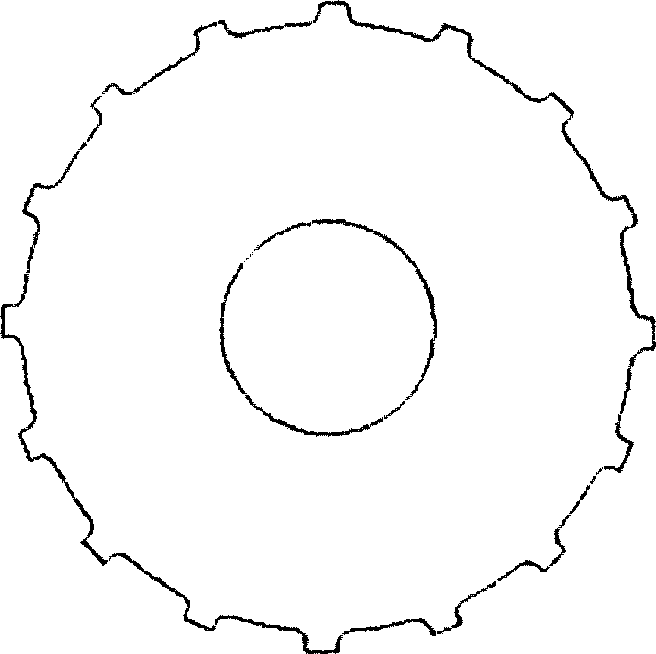

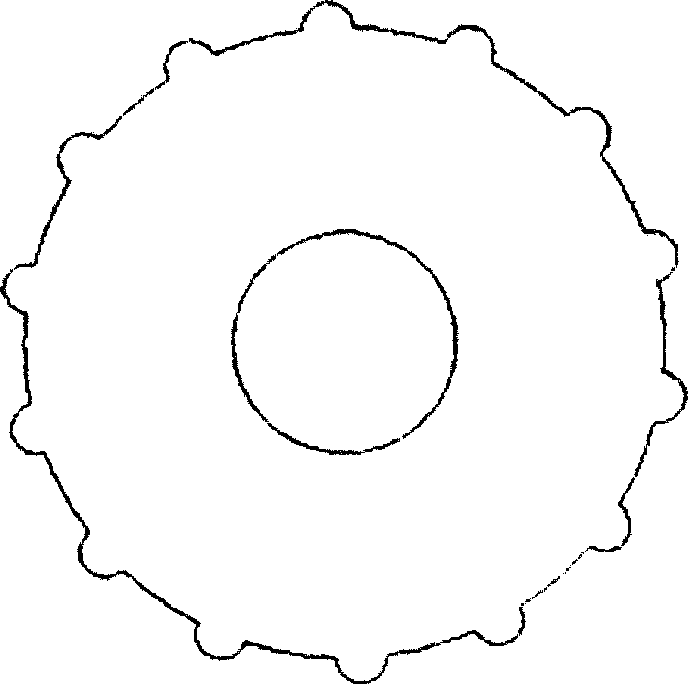

[0052] Refer to Fig. 1(b), Fig. 1(c), Fig. 1(d), Fig. 1(e), Fig. 1(f), Fig. 1(g). shape, convex sinusoidal, triangular or corrugated.

Embodiment 2

[0054] Refer to Fig. 1(h), Fig. 1(i), Fig. 1(j), the surface soil suppression rollers with bionic geometry structure, uniformly distributed, staggered and randomly distributed geometric structure of intermittent ribs along the roller alignment, the height of the ribs is 5mm~ 50mm, width 10mm~50mm, length 10mm~100mm, evenly distributed or staggered distributed rib-shaped structure with a rib spacing of 5mm~50mm; the substrate is made of cast iron or low carbon steel, and the bionic geometry is made of ultra-high molecular weight polymer. Vinyl or enamel-coated material; grooves are dug into the surface of the roller base.

[0055] Refer to Fig. 1(b), Fig. 1(c), Fig. 1(d), Fig. 1(e), Fig. 1(f), the cross-sectional profile of the rib adopts rectangle, circular arc, convex parabola, convex sinusoidal or triangle.

Embodiment 3

[0057] Referring to Fig. 2(a), the surface soil suppression roller with bionic geometric structure has a geometric structure of continuous ribs distributed along the circumference of the roller. Carbon steel material, bionic geometry adopts ultra-high molecular weight polyethylene material or enamel coating material; grooves are dug out on the surface of the pressure roller base.

[0058] Refer to Fig. 1(b), Fig. 1(c), Fig. 1(d), Fig. 1(e), Fig. 1(f), the cross-sectional profile of the rib adopts rectangle, circular arc, convex parabola, convex sinusoidal or triangle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com