Non-magnetic ultra-thin metal lower-beam honeycomb frame

An ultra-thin metal, magnetically conductive technology, applied in beehives, beekeeping, applications, etc., can solve problems such as shrinkage, and achieve the effect of increasing yield and improving the convenience of honey extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

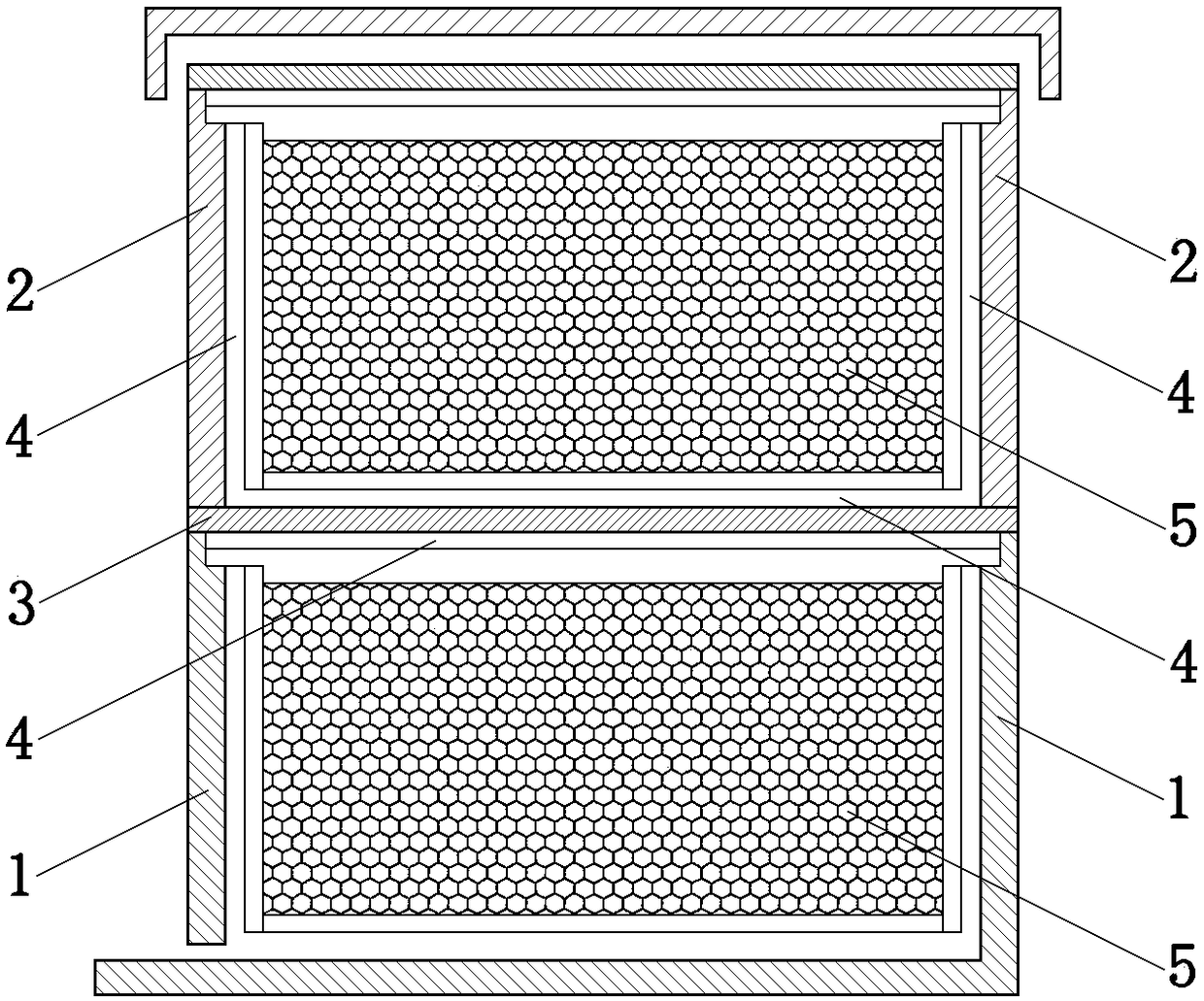

[0014] exist figure 1 Among them, people usually use the nest box 1, the successor box 2 and the whole queen partition 3 to raise bees, but the whole queen partition 3 is thick 13 millimeters, and the bee path (passage for honeybee activity) on the whole queen partition 3 is 4 wide 10 millimeters, the honeycomb road 4 wide 10 millimeters below the whole king partition 3, the thick 20 millimeters of frame upper beam, the thick 12 millimeters of nest frame lower beam, the distance of 65 millimeters altogether between upper and lower honeycomb 5, It is impossible to make the Chinese honeybee with weak natural group and the Western honeybee not strong enough to store honey in the successor box.

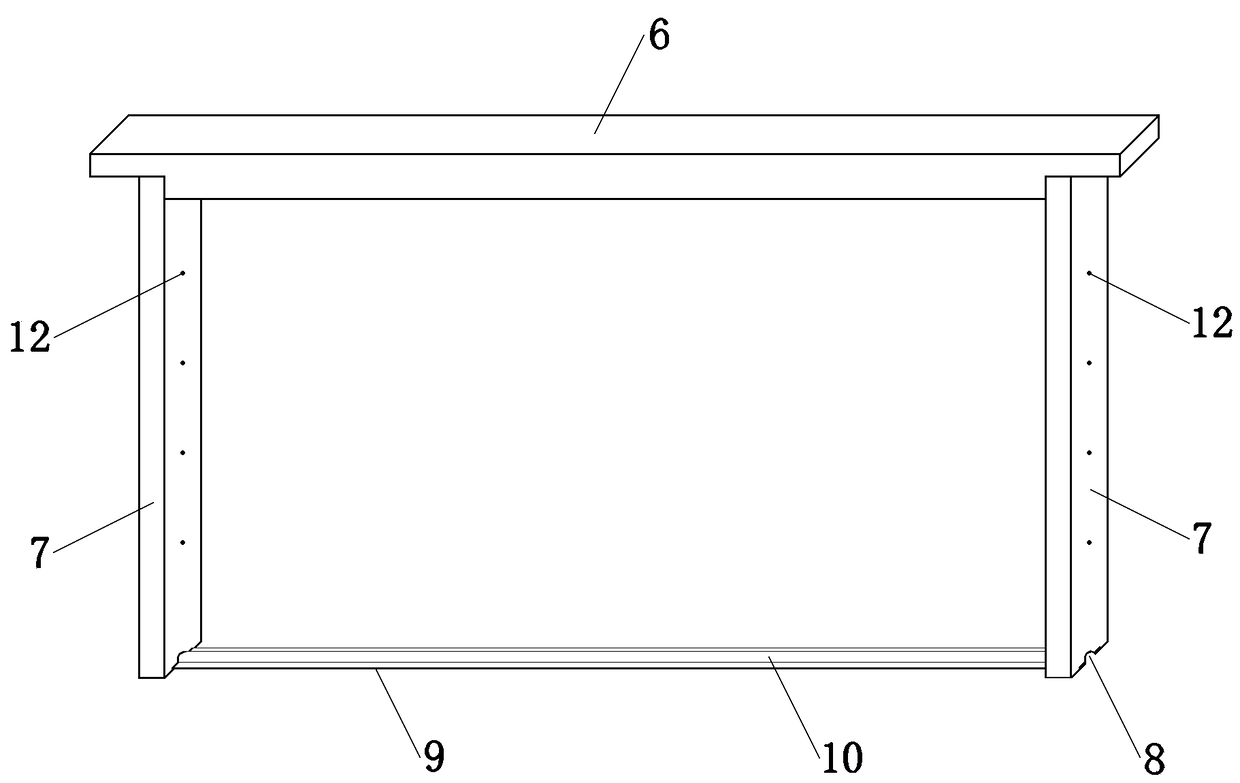

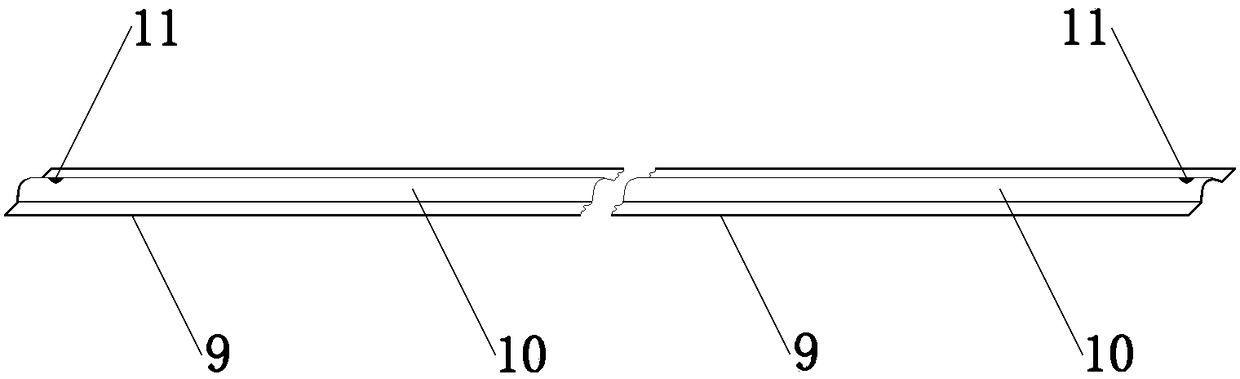

[0015] exist figure 2 In the shown embodiment, at the two ends of a nest frame upper beam 6, a nest frame side bar 7 is respectively fixed, and the lower end faces of the two nest frame side bars 7 each have a width of 6 to 10 mm. 3-6 mm deep, with a semicircular groove 8 with a screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com