Vibrating screen with various vibrating tracks

A technology of vibrating track and vibrating screen, which is applied in the direction of filter screen, solid separation, grid, etc., can solve the problem that the exciter cannot meet the production requirements, and achieve the effect of easy popularization, easy realization, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

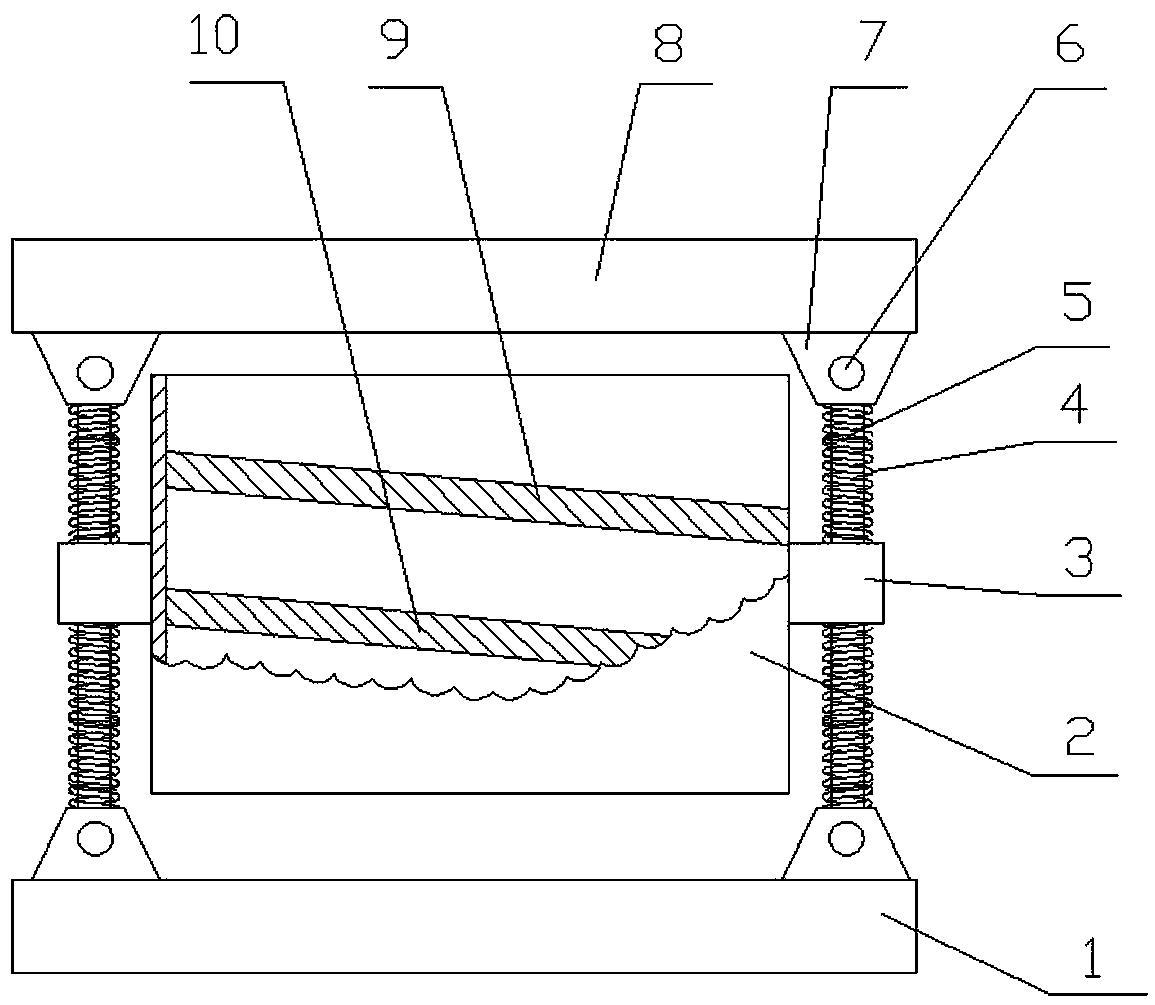

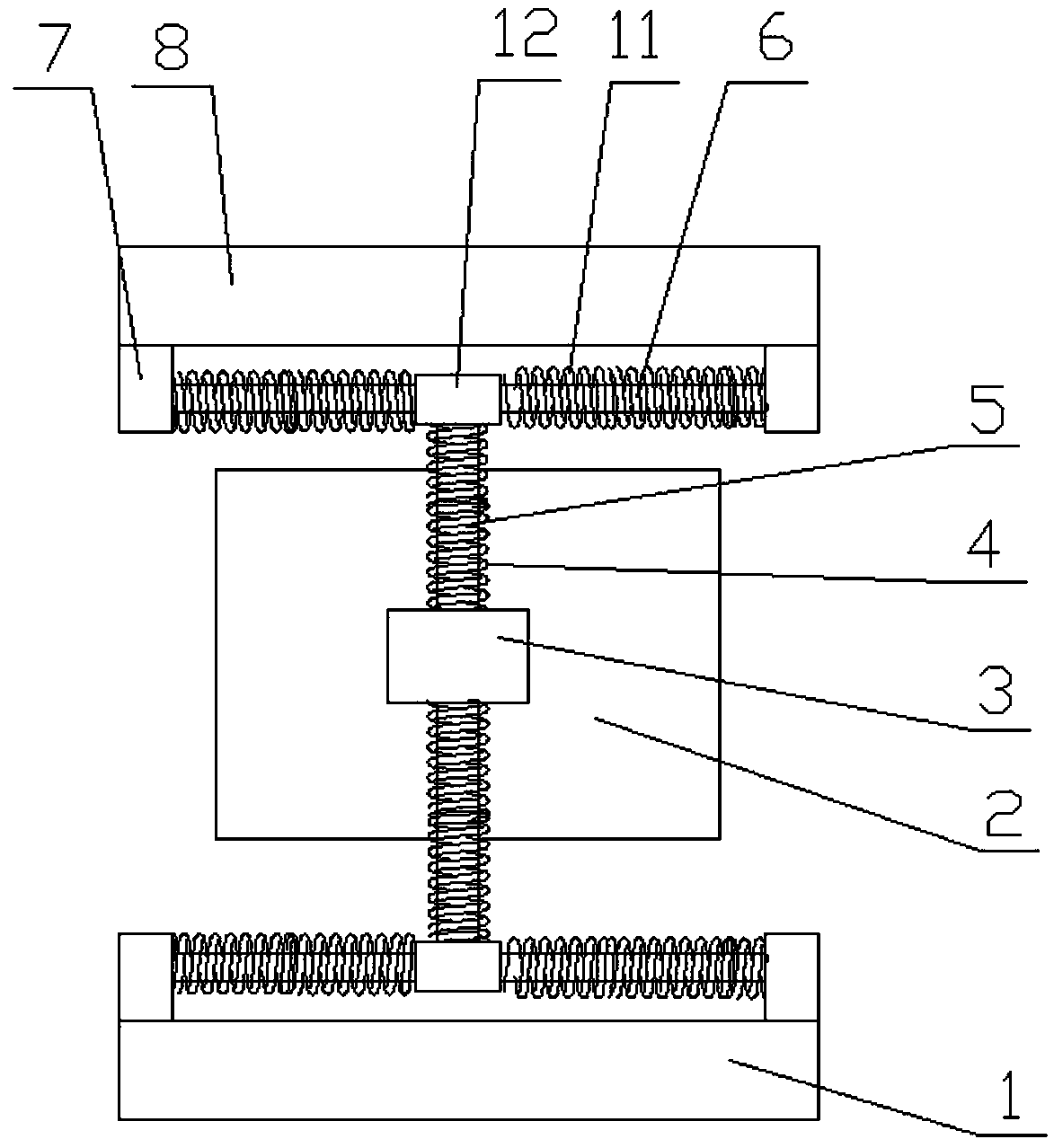

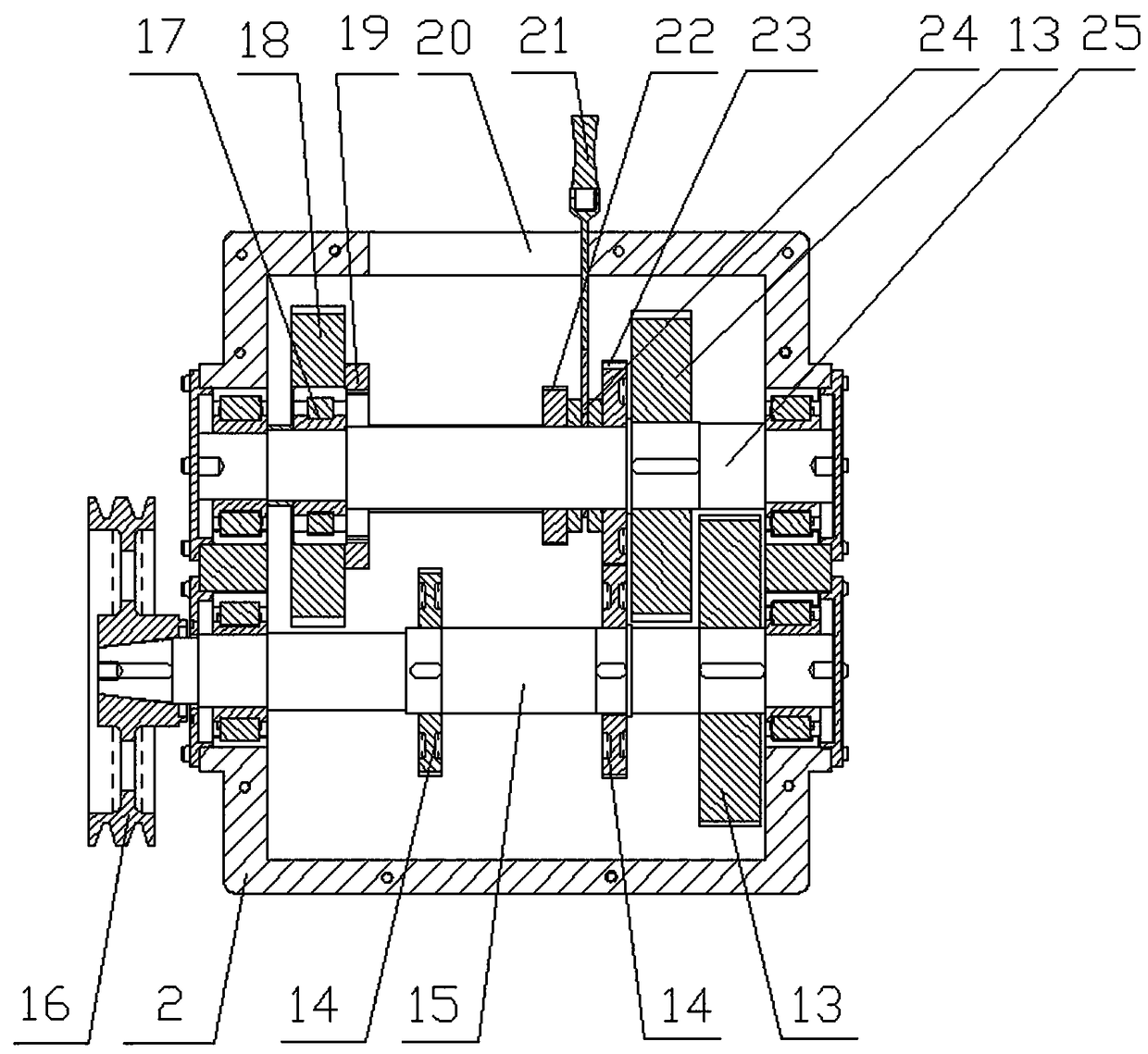

[0022] Such as Figure 1 to Figure 3 Shown, a kind of vibrating screen with multiple vibration tracks of the present invention comprises top frame 8, bottom frame 1 and is arranged on the screen box 2 between top frame 8 and bottom frame 1, top frame 8 and the bottom frame 1 are fixedly connected with other auxiliary bases, and the screen box 2 is movably connected between the top frame 8 and the bottom frame 1, and can be arranged along a straight line, Three kinds of vibration trajectories, circular and elliptical, vibrate to complete the screening operation.

[0023] On the bottom surface of the top frame 8 toward the bottom frame 1, the two ends of the screen box 2 are respectively provided with first slide bars 6 parallel to each other, and the top surface of the bottom frame 1 toward the top frame 8 is located at the bottom of the screen box 2. Both ends are respectively provided with the first slide bar 6 parallel to each other, the first slide block 12 is all slid on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com