Sheet clamping mechanism for automobile processing plate laser welding machine

A technology of laser welding machine and clamping mechanism, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of troublesome fixing and poor effect, and achieve the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

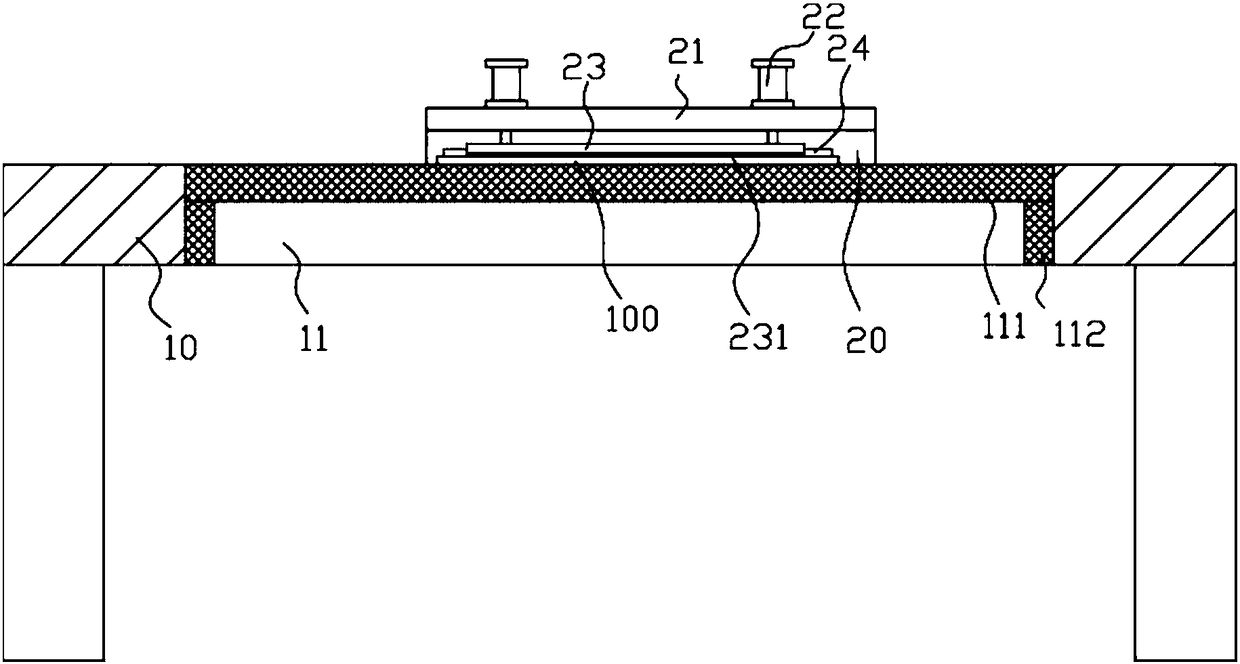

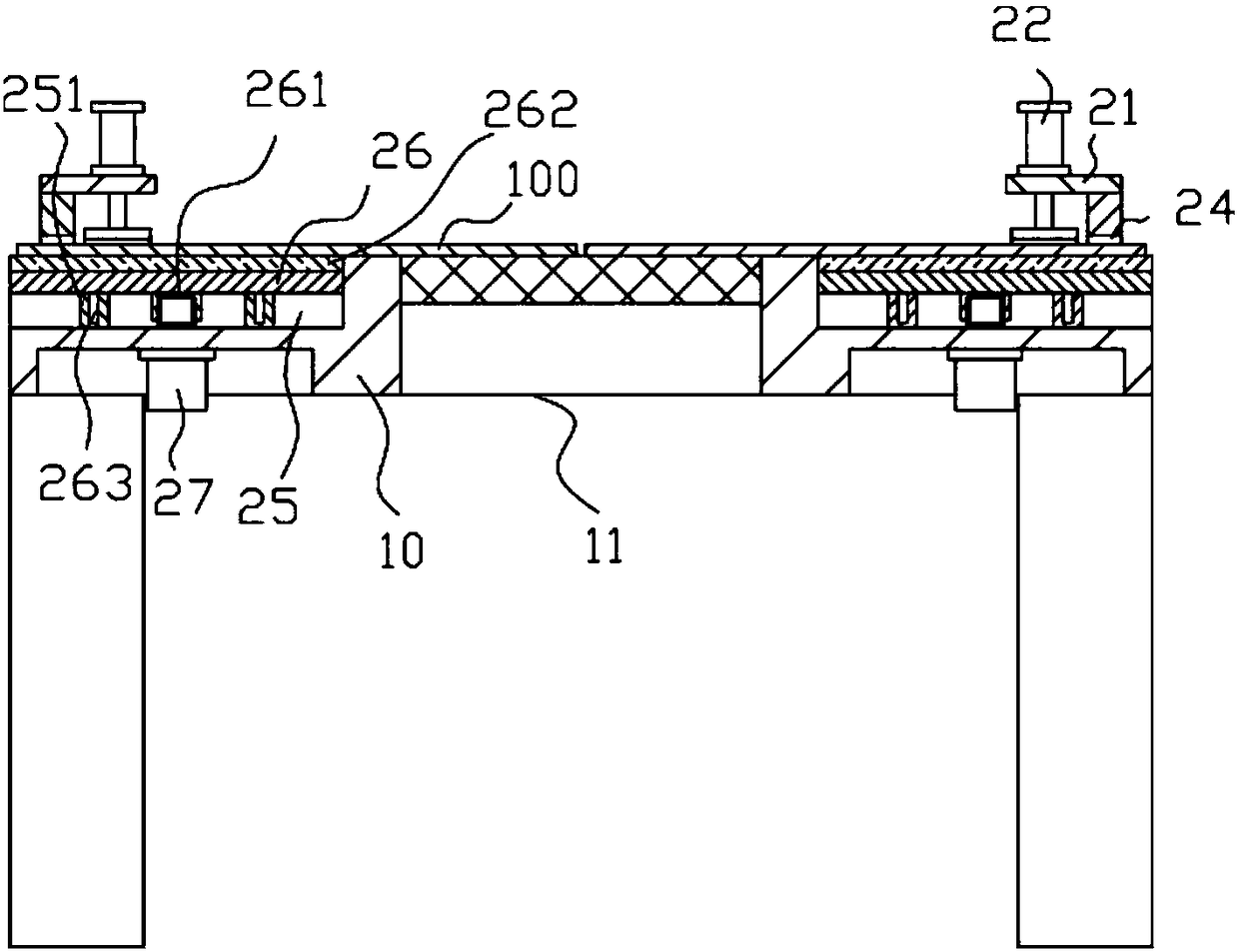

[0014] Example: see Figure 1 to Figure 2 Shown, a kind of sheet metal clamping mechanism for the laser welding machine of automobile processing plate comprises frame 10, and the middle part of the top plate of described frame 10 has processing through groove 11, and the frame 10 on the front and rear sides of processing through groove 11 The top surface of the top plate is fixed with a clamping support plate 20, the top surface of the clamping support plate 20 is fixed with a transverse clamping support plate 21, and the top surface of the transverse clamping support plate 21 is fixed with a plurality of upper compression cylinders 22, The push rod of the upper pressing cylinder 22 passes through the bottom surface of the transverse clamping support plate 21 and is fixed with an upper pressing plate 23. The middle part of the bottom surface of the clamping support plate 20 has a feeding channel 24, and the plate 100 to be processed is inserted and sleeved in the feeder. In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com