Automatic carrier overturning equipment

An automatic flipping and equipment technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low production efficiency, time-consuming and labor-intensive, etc., achieve high production efficiency, high degree of intelligent control, and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

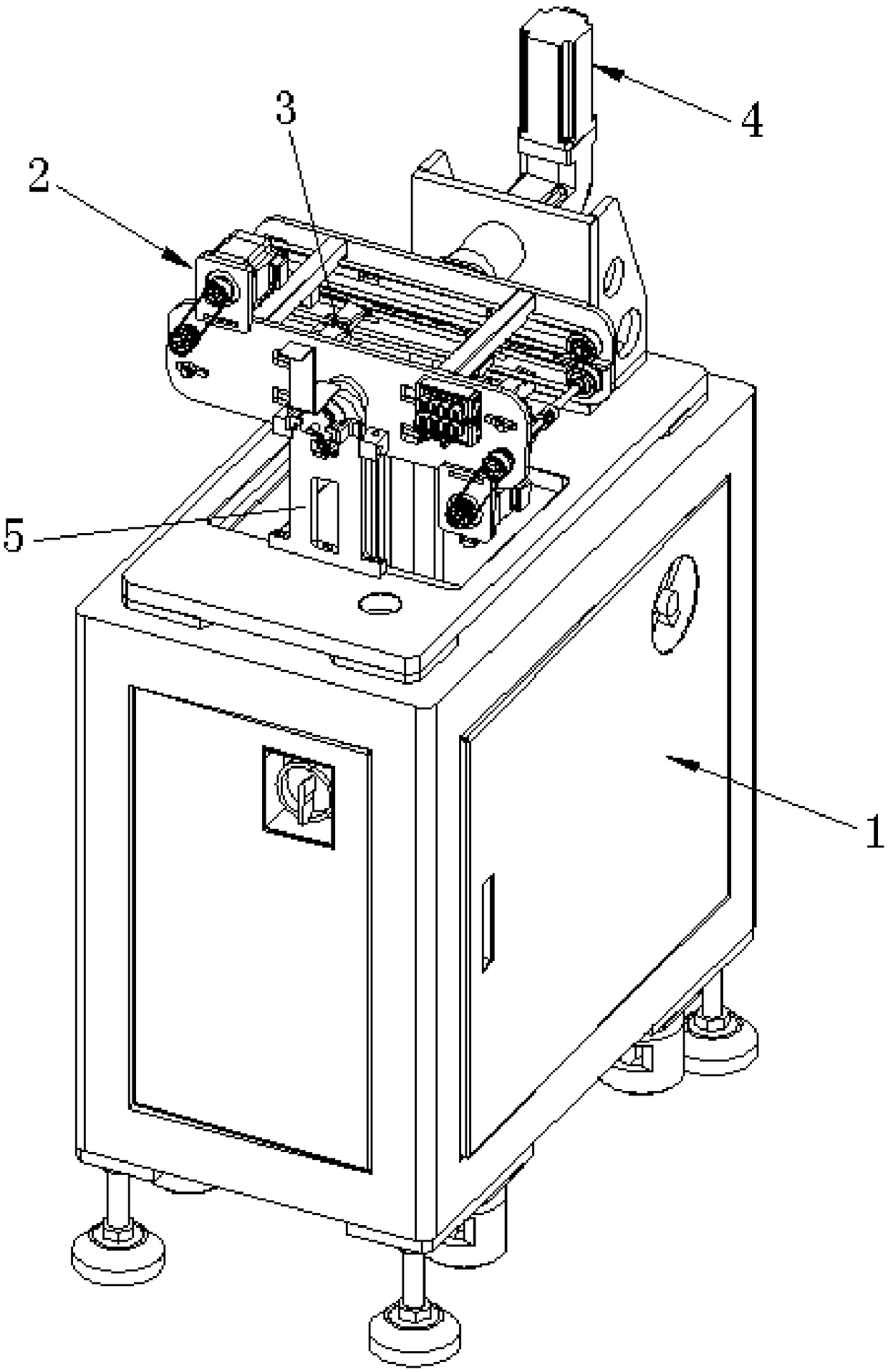

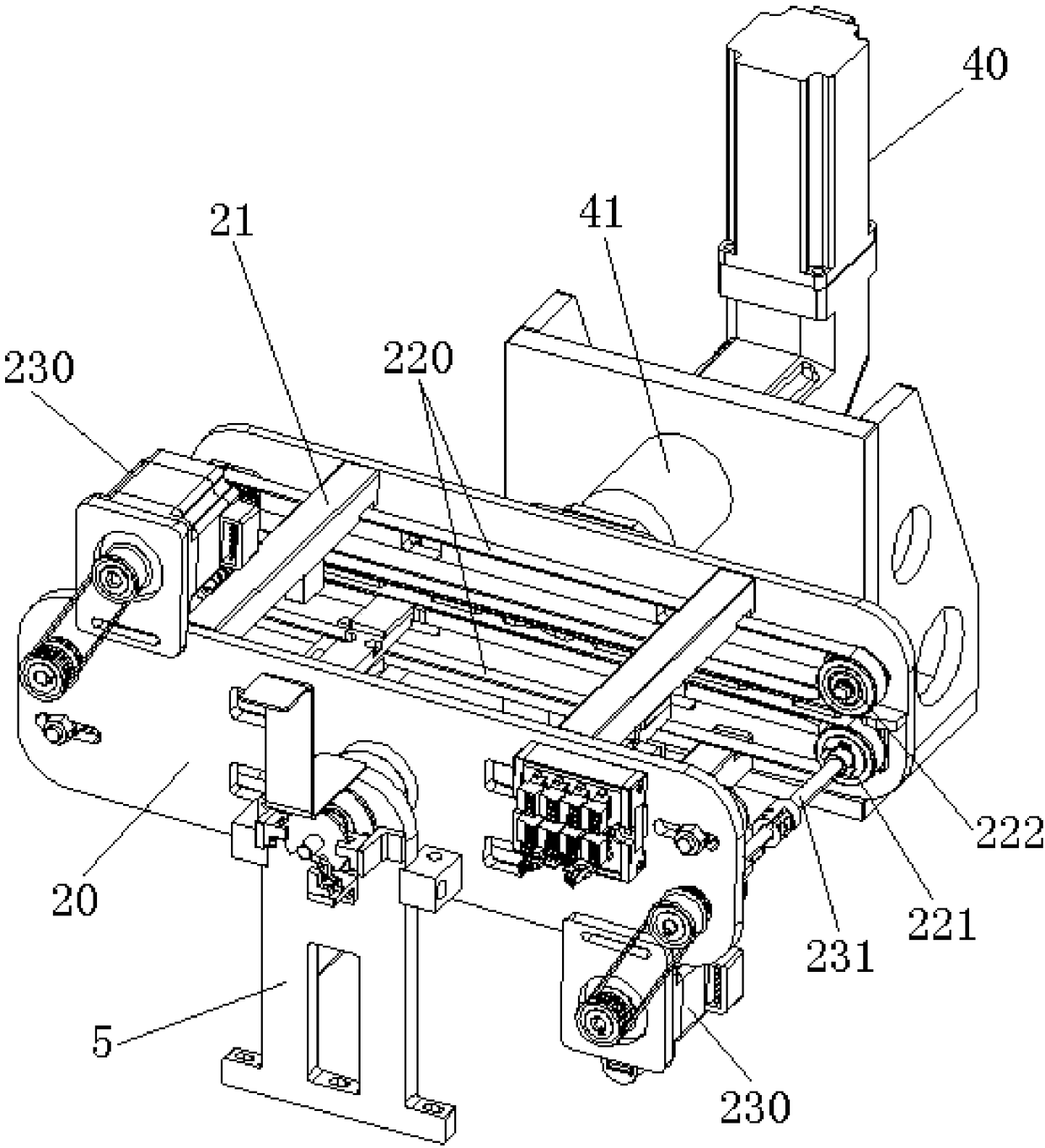

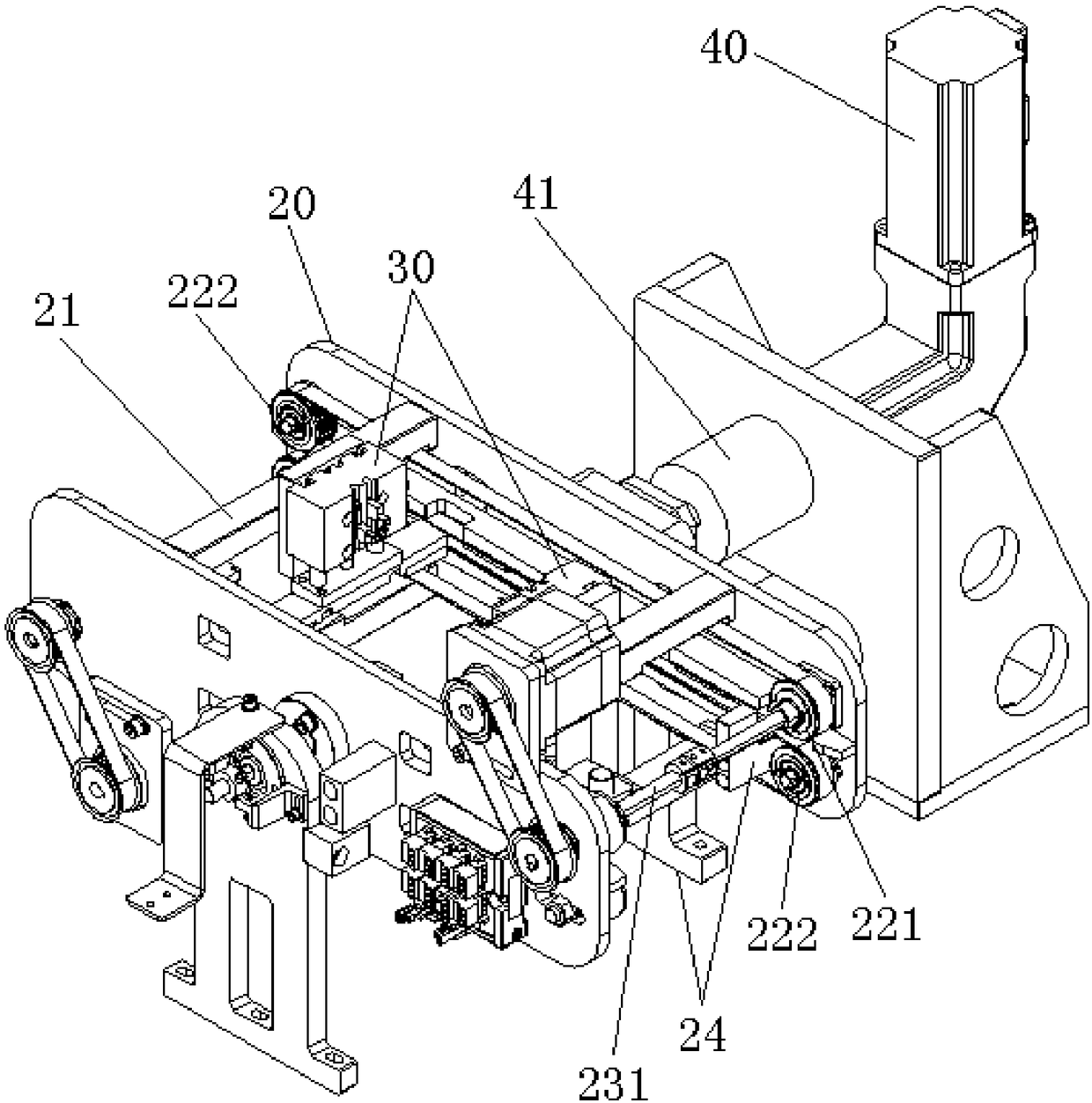

[0032] Please refer to the attached figure 1 As shown, it is a schematic diagram of a partial three-dimensional structure of the first embodiment of the automatic carrier turning device of the present invention. The automatic turning device of the carrier includes a base box 1, a conveying mechanism 2 for conveying the carrier, a clamping mechanism 3 and a turning mechanism 4, wherein the conveying mechanism 2 is arranged on the top of the base box 1 On the side, the clamping mechanism 3 is arranged on the conveying mechanism 2, and can clamp and loosen the carrier; the turning mechanism 4 is also arranged on the top side of the base box 1, and when the When the clamping mechanism 3 clamps the carrier, the turning mechanism 4 can drive the conveying mechanism 2, the clamping mechanism 3 and the carrier to turn over together.

[0033] In this embodiment, preferably, refer to the attached figure 1 And attached figure 2 As shown, two support stands 5 are positioned on the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com