A feed structure for a food warehouse

A food material and material feeding technology, which is applied in the field of food material warehouse feeding structure, can solve the problems that the space under the food storage cavity is not fully utilized, the food is dry and thin, and troublesome

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

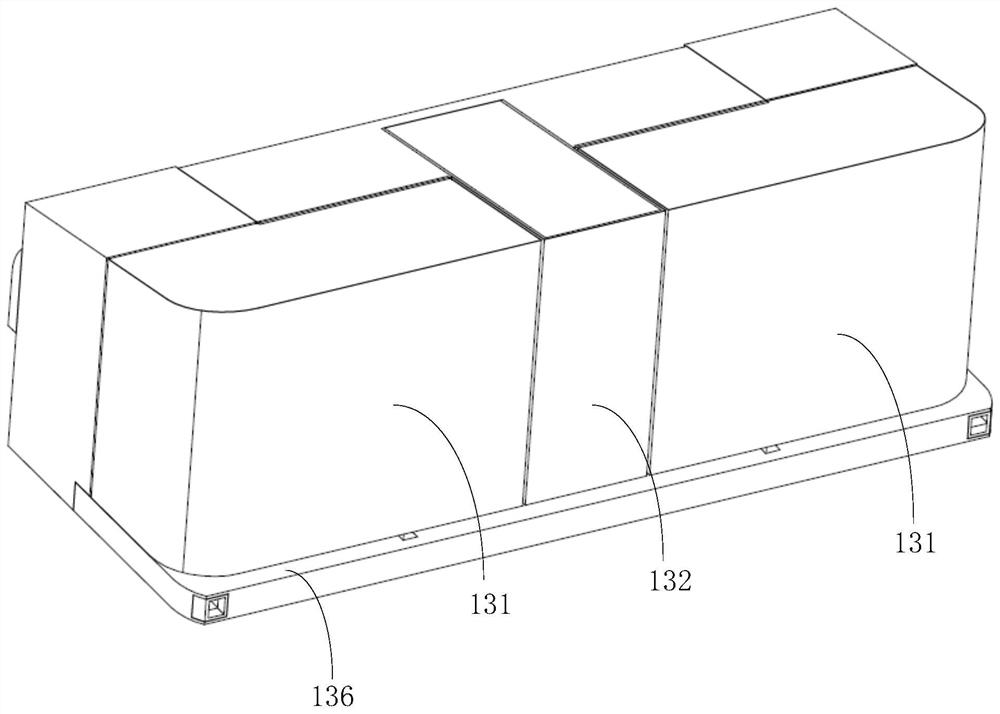

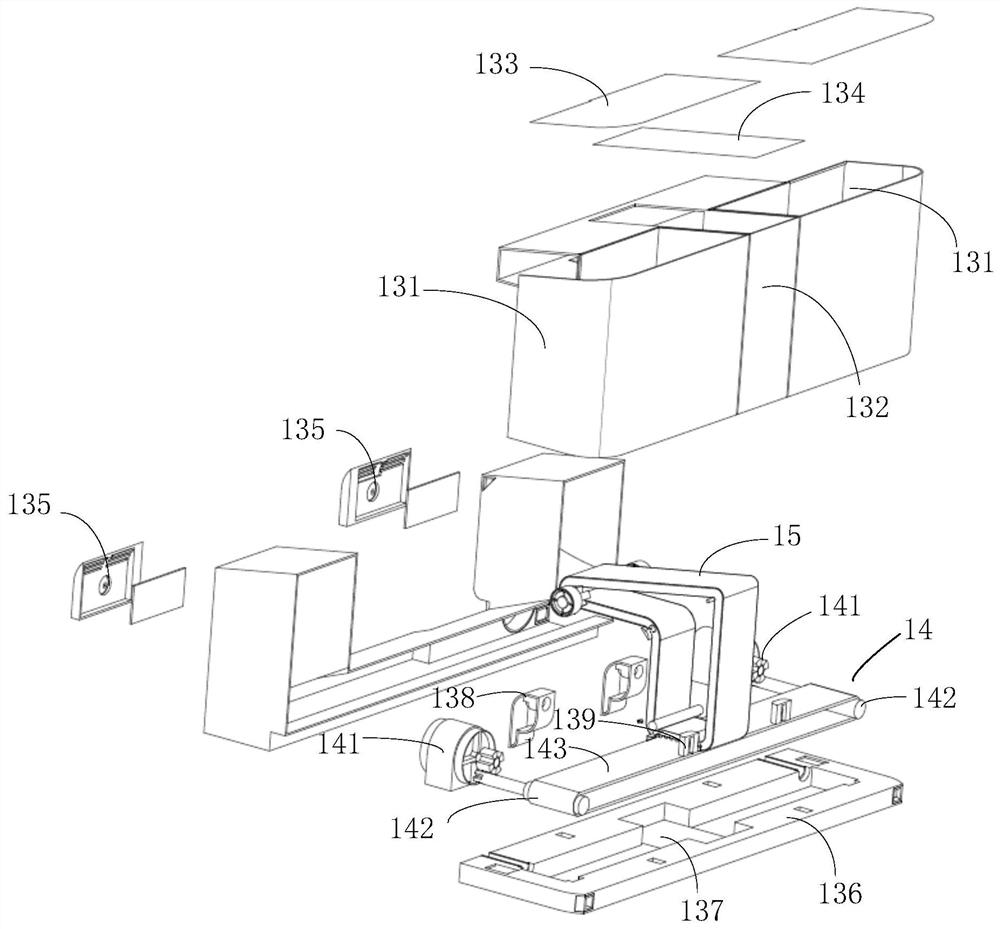

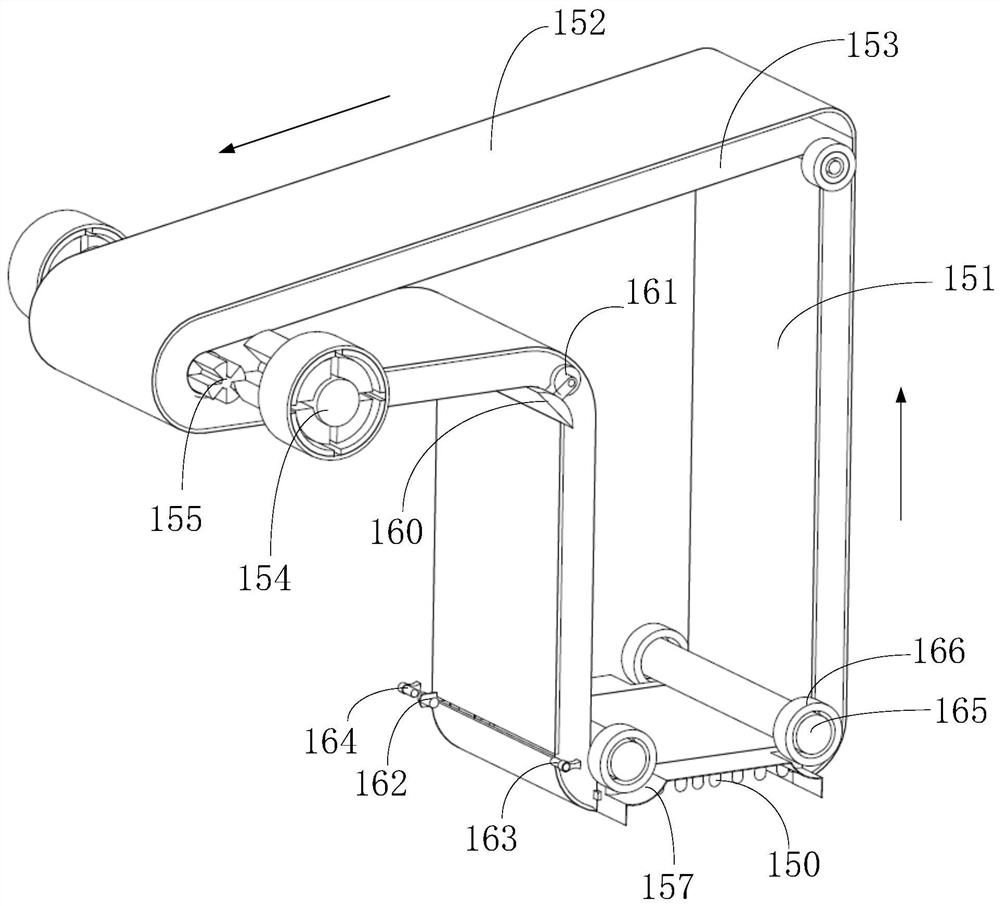

[0025] Such as Figure 1 to Figure 4 As shown, a material bin feeding structure includes a food bin 131 for storing ingredients. There is a second conveying mechanism 15 intersecting with the first conveying mechanism 14 for lifting and sending out food materials.

[0026] The ingredients are conveyed by two transmission mechanisms, the ingredients can be sent out from the ingredient bin 131, and the lifting from the low position to the high position can be realized, so that the food bins 131 can be arranged side by side on the cleaning layer side, not limited to cleaning Above the floor, during use, food materials can be lifted by the second conveying mechanism 15 and delivered to the entrance above the cleaning floor, thereby making full use of the space below the traditional storage floor.

[0027] Further, the first transmission mechanism 14 is a conveyor belt 143 driven by a motor 141 , the conveyor belt 143 is arranged on the transmission roller 142 , and the motor 141 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap