Laying device for stand column maintaining films

A technology of laying device and curing film, which is applied in the field of construction tools, can solve the problems of low work efficiency, low safety factor, and difficult laying of column curing film, and achieve the effect of moisturizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to illustrate the technical features of the solution more clearly, the solution will be described below through specific implementation modes.

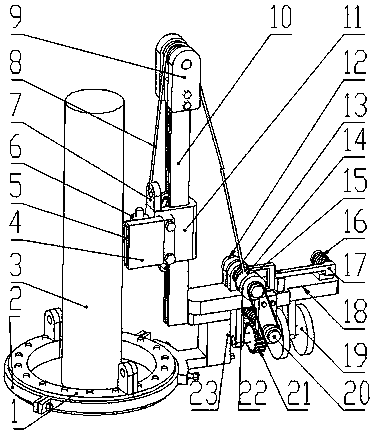

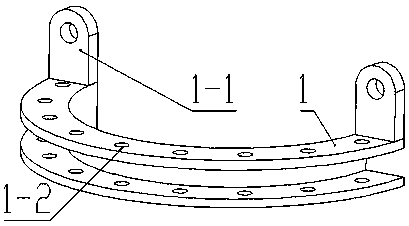

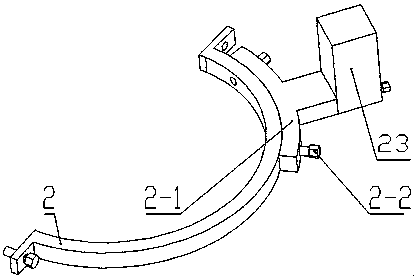

[0039] refer to figure 1 , a column curing film laying device, including a track assembly that makes the laying device rotate around the column 3, the curing film 6 is arranged on the curing film seat 11, and the curing film seat 11 is movably connected to adjust the laying height of the curing film 6 The adjustment assembly, the height adjustment assembly is connected to the power mechanism for driving the curing film 6 to rise;

[0040] The side of the curing film seat 11 is fixedly provided with an exhaust assembly for discharging gas from the multi-layer curing film 6;

[0041] The power mechanism also includes an electromagnetic auxiliary transmission assembly for adjusting the rising state of the curing film 6 .

[0042] The power mechanism is used to make the curing film seat drive the curing film to rotate ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com