Coaxiality test tool

A coaxiality and inspection tool technology, which is applied to measuring devices, instruments, and mechanical devices, etc., can solve the problem of difficulty in measuring the coaxiality of the inner cavity of the inner ball joint shell and the rod.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

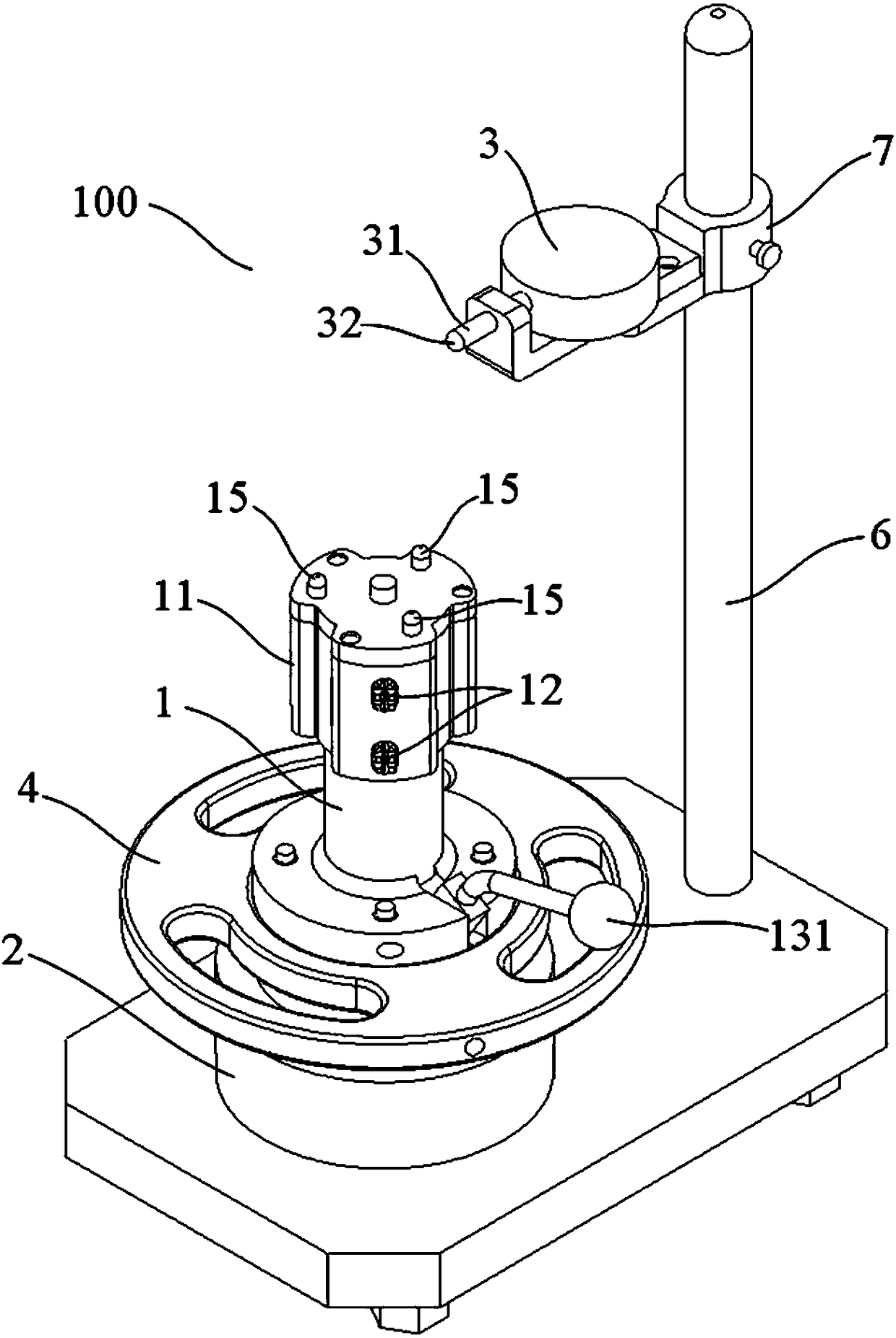

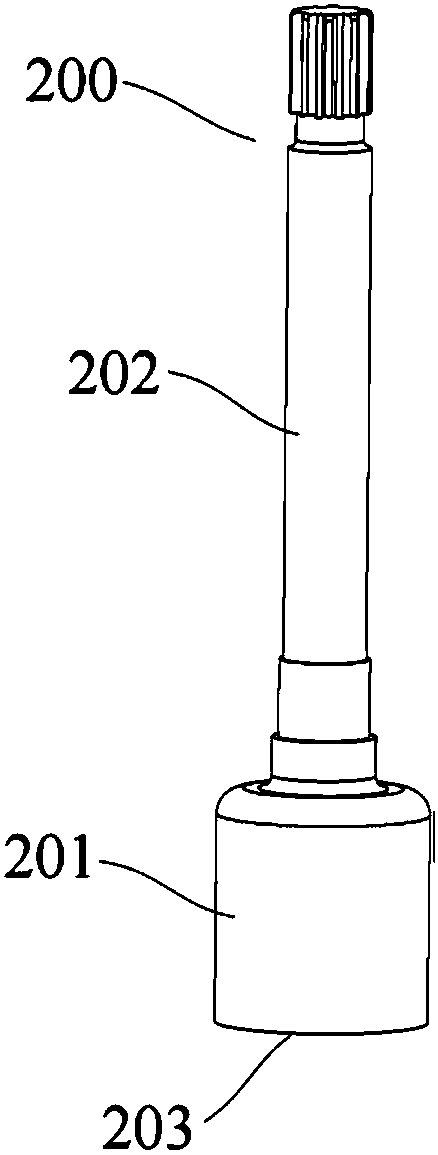

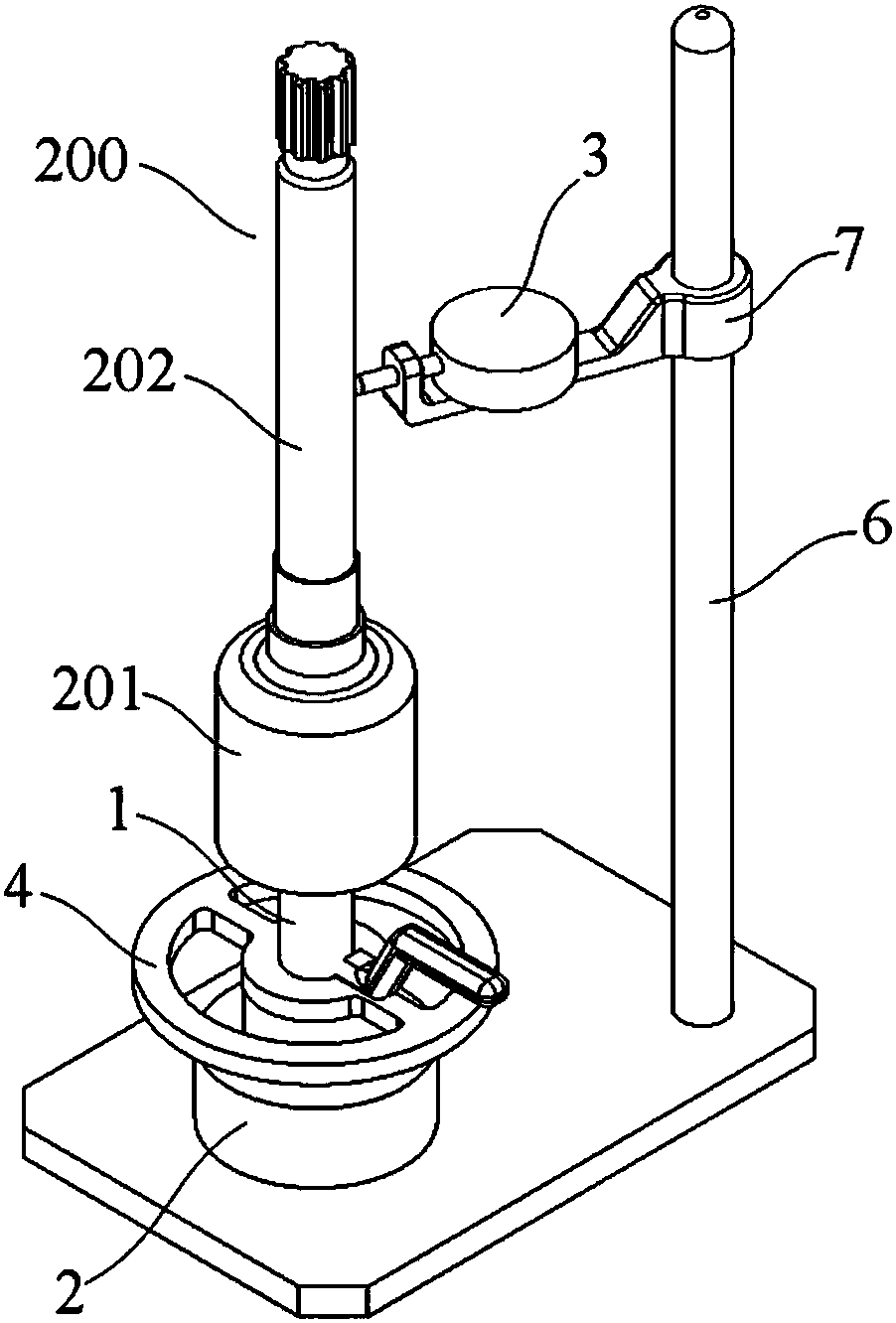

[0071] Such as figure 1 Shown is an embodiment of the coaxiality inspection tool 100 of the present invention. The workpiece 200 detected by the coaxiality inspection tool 100 is as figure 2 As shown, the workpiece 200 includes a workpiece body 201 and a rod portion 202. The workpiece body 201 has an inner cavity 203 sunken inward, and the rod portion 202 is fixedly connected to the workpiece body 201. extend in the same direction. The workpiece 200 may be an inner ball joint, or a part similar to an inner ball joint.

[0072] Such as figure 1 , Figure 4 to Figure 6 As shown, the coaxiality inspection tool 100 includes a support body 1, a base 2 and a dial indicator 3, the support body 1 includes a support block 11 and a plurality of matching parts 12, and the plurality of matching parts 12 are arranged on the outer per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com