Accurate calibration method of image surface of optical camera

An optical camera and calibration method technology, applied in image analysis, image data processing, instruments, etc., can solve the problems of uniform field manufacturing difficulty, unfavorable engineering application, affecting display effect, etc., and achieve great scientific and engineering application value and application value. High, breaking through the technical bottleneck effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

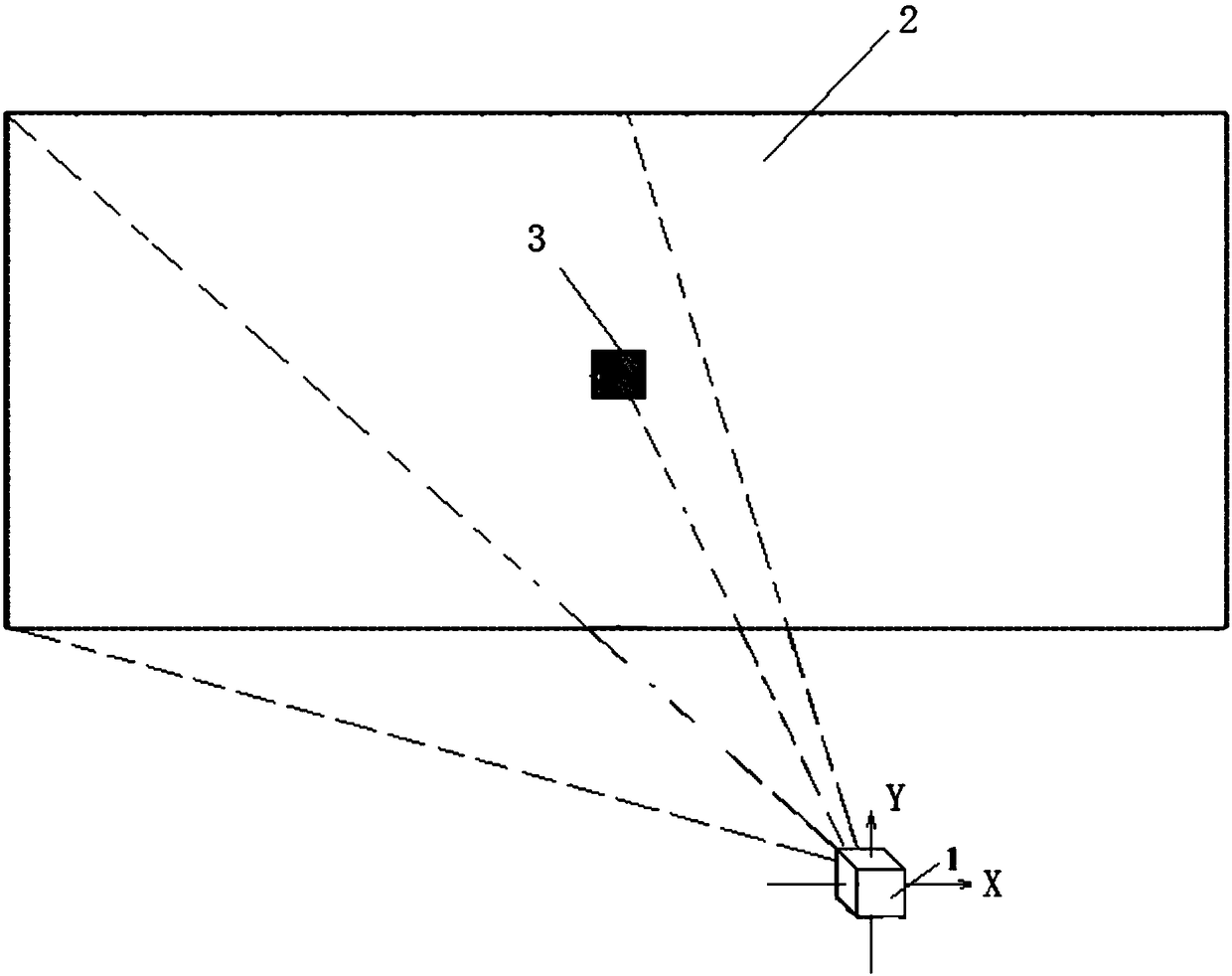

[0031] Such as figure 1 As shown, a calibration target 3 with constant brightness is fixed in the center of the display screen 2, and the calibration target 3 contains a single or multiple red, green and blue three-color light-emitting chips; the camera 1 is fixed on a platform with two degrees of freedom, Camera 1 can perform pitch rotation around the X-axis and azimuth rotation around the Y-axis on the gimbal; when camera 1 returns to the zero position, the pitch angle and azimuth angle are both zero, and the lens of camera 1 is facing the display screen 2 at this time The center normal direction of . Described camera 1 adopts CMOS type or CCD scientific type or industrial type camera, also can adopt single-lens reflex civilian camera and mobile phone.

[0032] Since the effective viewing angle of camera 1’s effective field of view in the horizontal direction is generally within ±20°, the angle step range of the control pan / tilt in the effective field of view in the horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com