A fixture device for pressing PCB

A fixture device and matching block technology, applied in the direction of laminating printed circuit boards, assembling printed circuits with electrical components, printed circuits, etc., can solve the problems of increasing material costs and production costs, different positions of pressing areas, etc., to save materials. , The effect of smart design and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation structure of the present invention will be described below in conjunction with the accompanying drawings.

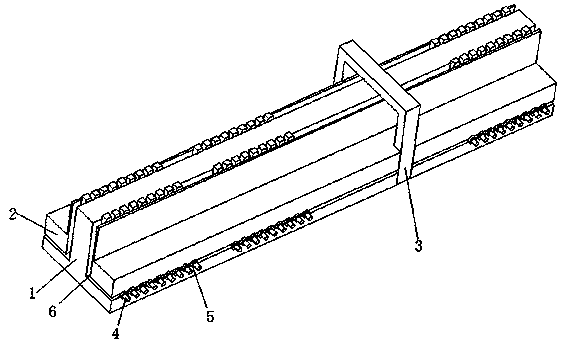

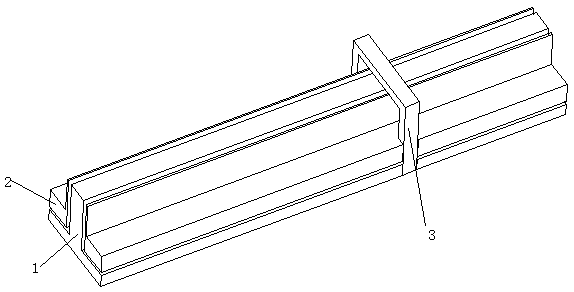

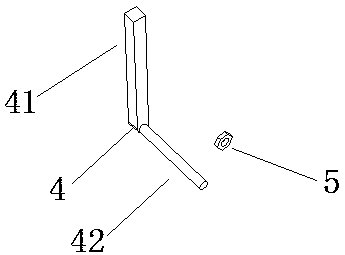

[0020] Such as Figure 1 to Figure 5 As shown, the fixture device for pressing PCB of the present invention includes a main body block 1, a mating block 2, a fixed block 3, an L-shaped support 4 and a nut 5; the main body block 1 is T-shaped, and the mating block 2 is set There are two pieces, symmetrically arranged on both sides of the main block 1; the main block 1 and the matching block 2 are connected and fixed by the fixing block 3, and an L-shaped sliding channel 6 is formed between the main block 1 and the matching block 2; the sliding channel 6 can accommodate a plurality of L-shaped supports 4, the vertical length and horizontal length of the L-shaped support 4 are respectively greater than the vertical length and the horizontal length of the sliding channel 6; the L-shaped support 4 is composed of a cuboid 41 and The other end is inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com