Automatic textile cloth cutting device

A cutting device and technology for textile fabrics, which are applied in the cutting of textile materials, textiles and papermaking, and fabric surface trimming, etc., can solve the problems of uneven fabric edges, inability to level fabrics, and low cutting efficiency, and achieve improved Work efficiency, ease of cutting, and the effect of improving the competitiveness of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

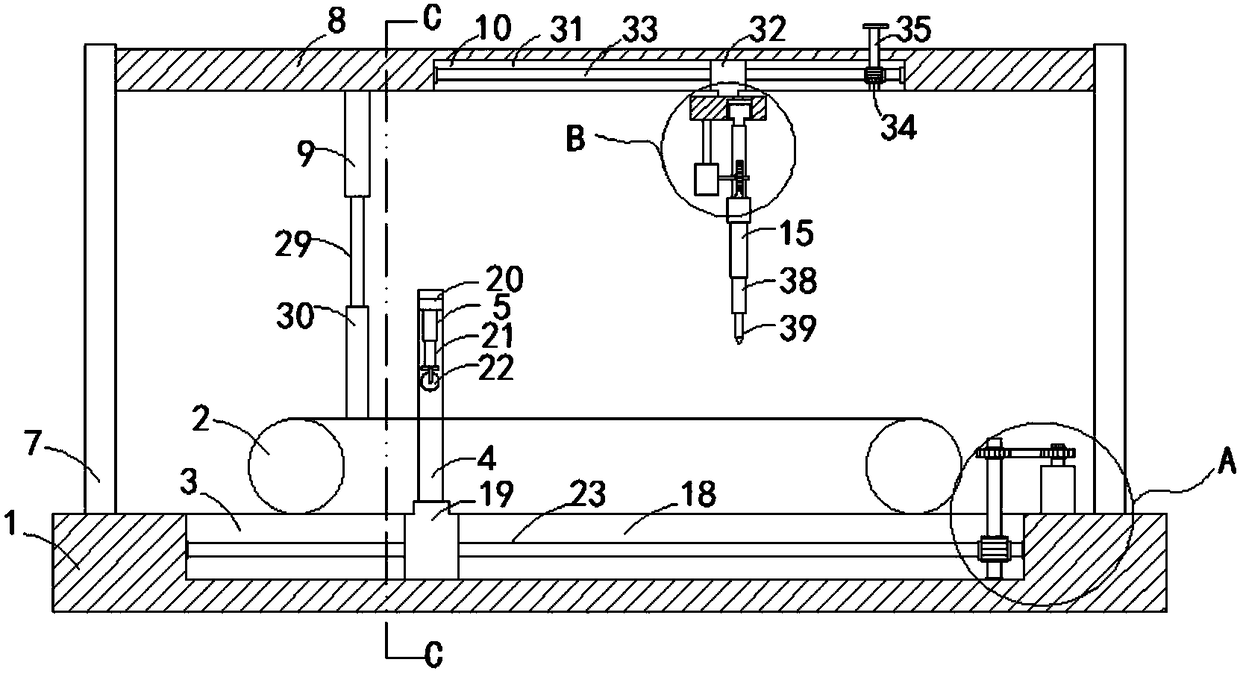

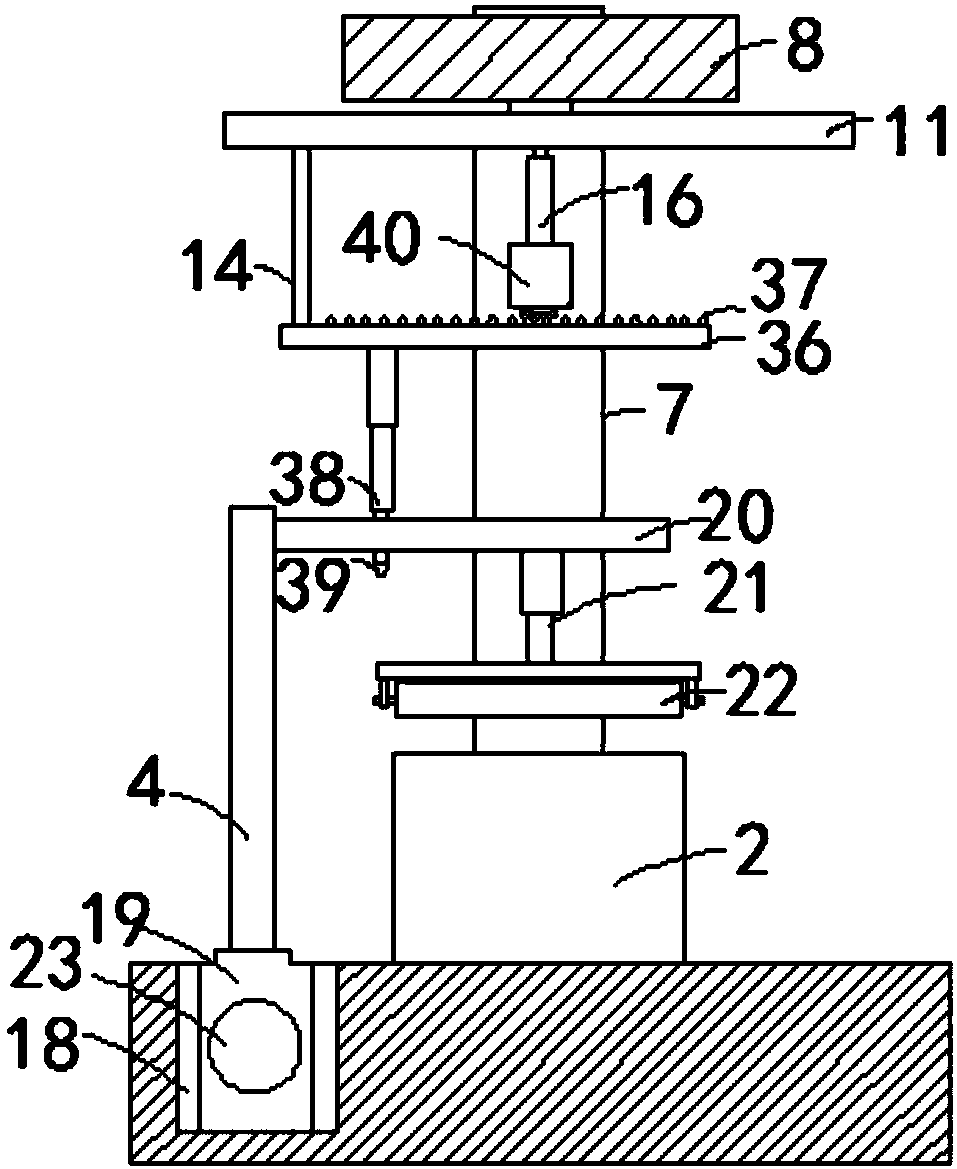

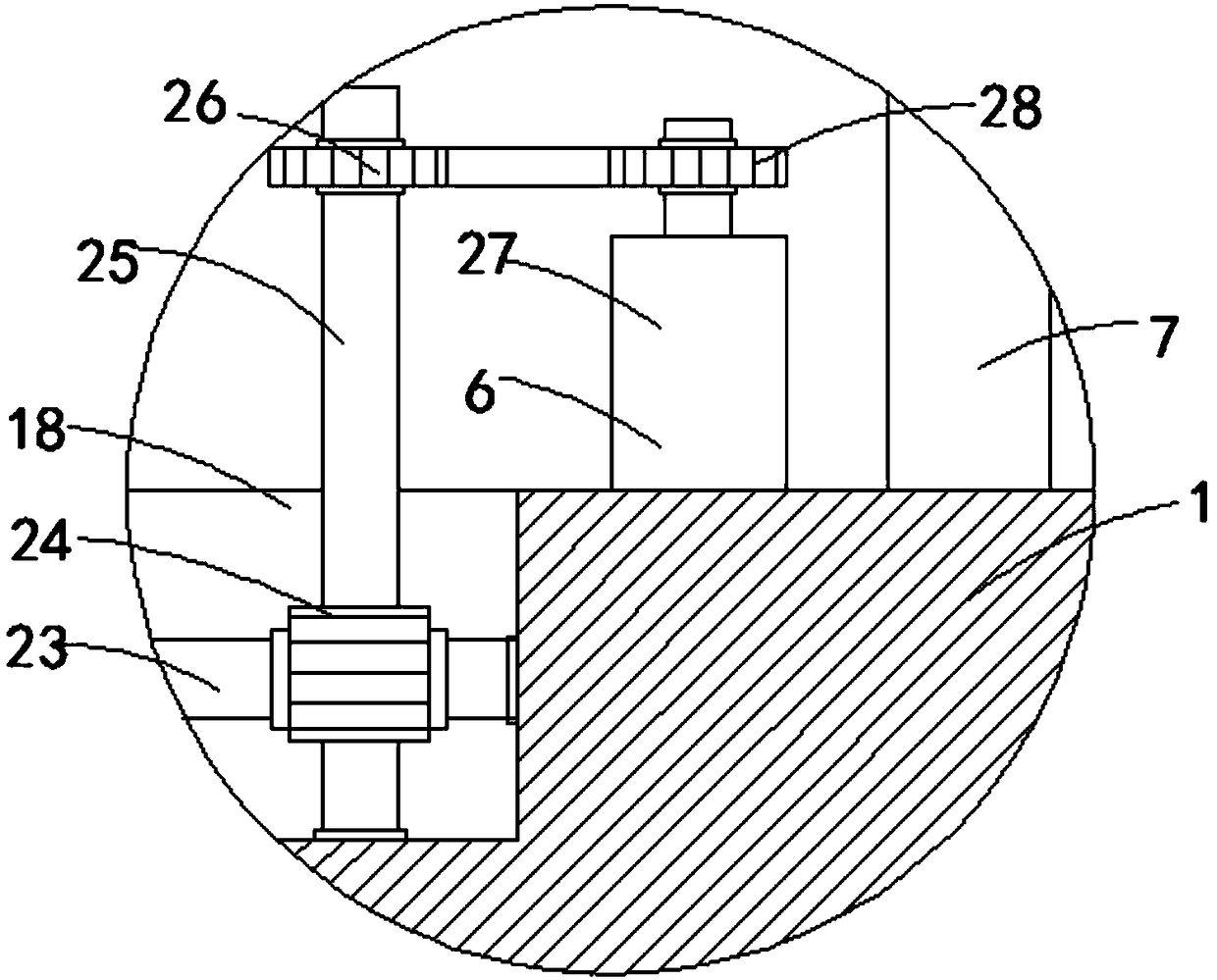

[0022] like Figure 1-4 As shown, an automatic textile cloth cutting device includes a base 1, a conveyor belt 2 is arranged on the base 1, and the conveyor belt of the conveyor belt 2 is made of a metal material, and the base 1 is provided with a first sliding mechanism 3, and the first sliding The mechanism 3 is arranged parallel to the conveyor belt 2, the upper end of the first sliding mechanism 3 is provided with a support rod 4, and the side wall of the support rod 4 is provided with a leveling device 5, and the leveling device 5 is located directly above the conveyor belt 2, on the base 1 The first rotating device 6 is provided, and the first rotating device 6 is engaged with the first sliding mechanism 3, and the base 1 is provided with two vertical boards 7, and the two vertical boards 7 are respectively arranged on the base 1 at the left and right ends of the conveyor belt 2 A horizontal plate 8 is arranged between the two vertical plates 7, and the horizontal plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com