Bamboo square strip floor and mounting process

A bamboo square and floor technology, applied in the direction of floor, building, building structure, etc., can solve the problems of complex process, and achieve the effect of unique concept, convenient paving and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

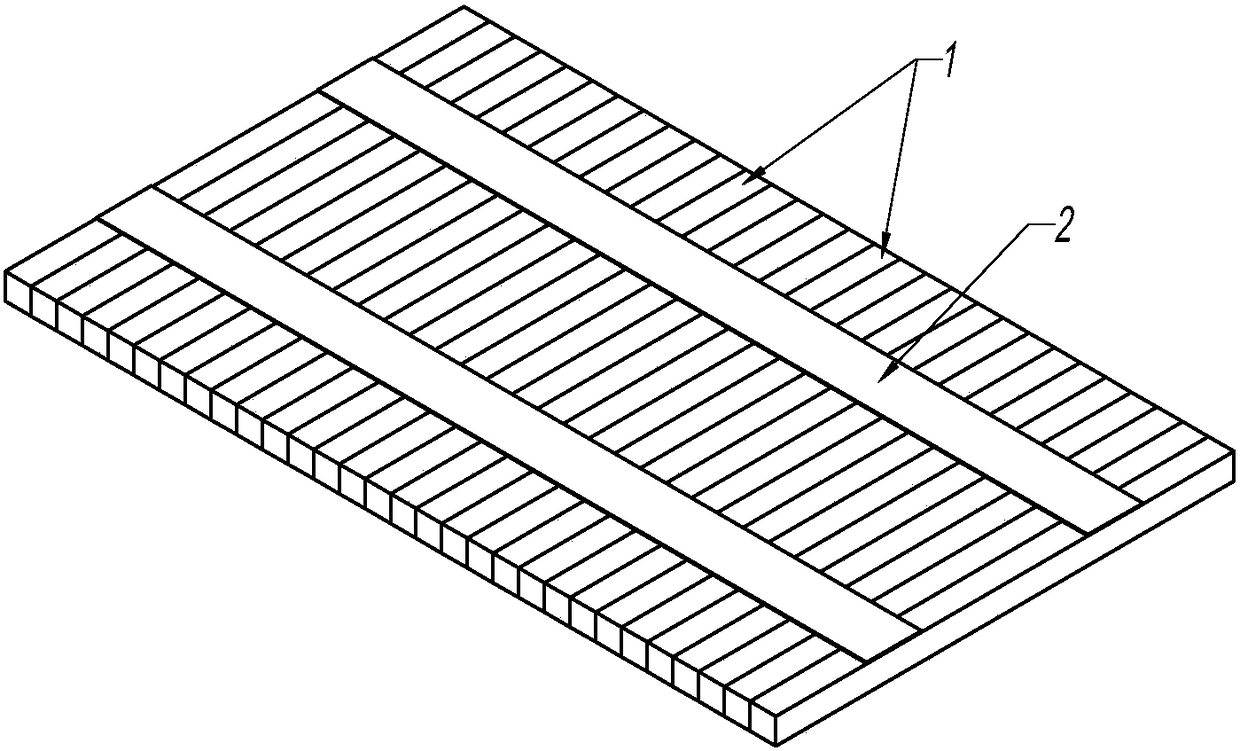

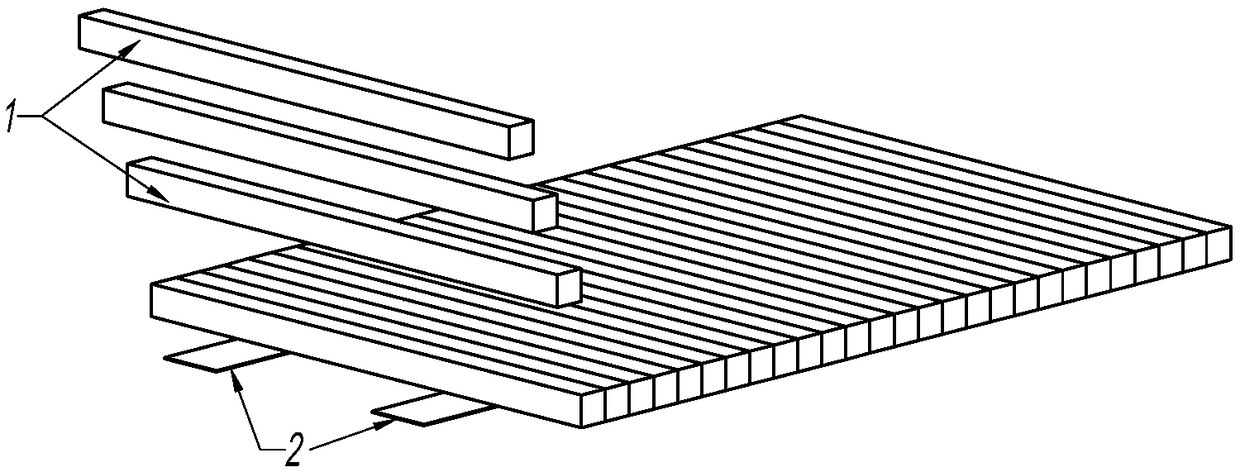

[0022] refer to figure 1 and figure 2 , Bamboo strip floor, made of bamboo square strips 1 with a side width of 8-15mm and a length of 140-300mm, which are neatly arranged side by side and bonded with adhesive tape 2 on one or both sides. 2 Generally, two steps can be used to reliably position the bamboo strip 1, so as to facilitate the operation during paving; while the total width occupied by the adhesive tape 2 is less than one-third of the length of the bamboo strip 1, leaving more room for paving When the viscose penetrates into the cracks between adjacent bamboo square strips 1, the effect of three-sided bonding is achieved. For this reason, under the premise that the width of the adhesive tape 2 has sufficient strength during operation, reduce the total width of the adhesive tape 2 as much as possible. When two adhesive tapes 2 are not stable enough, three narrower adhesive tapes can be considered.

[0023] According to different bamboo materials, different specifica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com