Core for high-efficiency high-speed box sealing machine and using method thereof

A case sealing machine, high-speed technology, used in packaging sealing/tightening, transportation packaging, thin material handling, etc., can solve the problems of easy tape fall off, unreliability, and many problems, and achieve scientific and reasonable structure of the movement. Wide range, easy to use and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

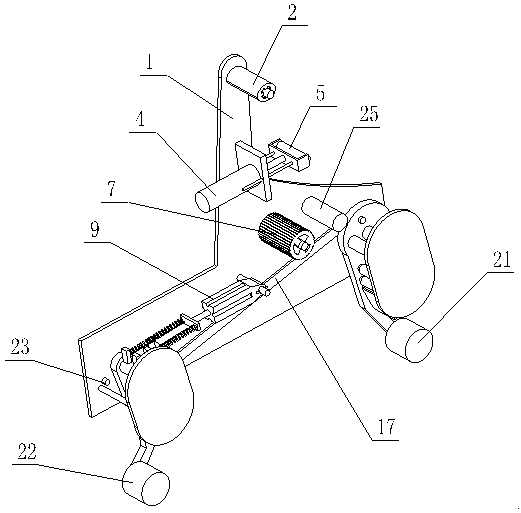

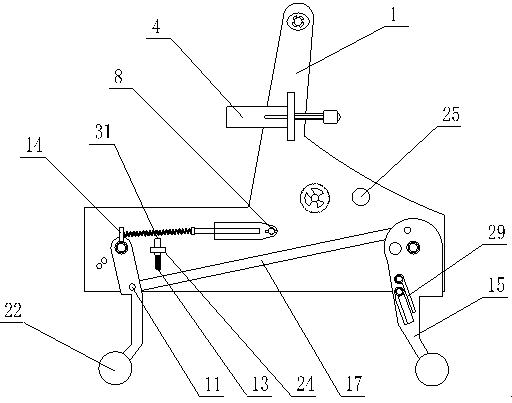

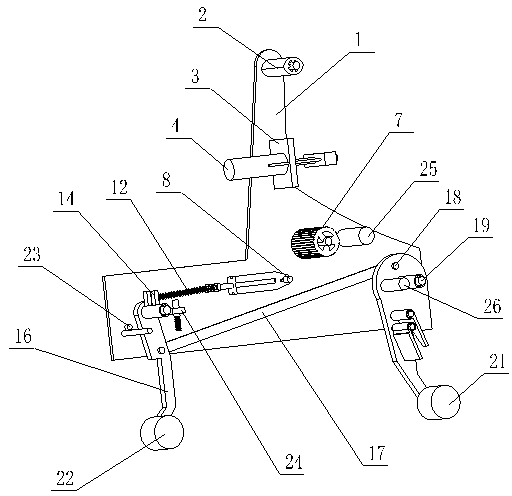

[0023] For specific example one, please refer to Figure 1-5, the movement of the high-efficiency high-speed sealing machine, including the main fixed plate 1, cylinder one 4, return spring 12 and spring 13, forearm 15, rear arm 16, connecting rod 17 and cylinder two 9, the top of the main fixed plate 1 A tape roll fixed core seat 2 is fixed, a variable tension mechanism support 3 is fixed in the middle of the main fixed plate 1, a forearm rotating shaft 19 and a rear arm rotating shaft 20 are fixed in the bottom of the main fixed plate 1, and the main fixed plate 1 One-way knurling wheel 7 and adhesive tape guide wheel one 25 are fixed on it, and described cylinder one 4 is fixed on the variable tension mechanism support 3, and the push rod top of described cylinder one 4 is fixed with pre-stretching roller 5, and described The corresponding pre-stretching roller 5 on the variable tension mechanism support 3 is provided with a guide rod 6, the forearm 15 can rotate around the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com