Dyeing and finishing system and process of plain polyester filament yarn-dyed fabric

A fabric dyeing and finishing technology, applied in the processing of textile materials, textile processing machine accessories, equipment configuration for processing textile materials, etc., can solve the problems of dyeing speed and efficiency discount, and achieve the effect of improving dyeing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

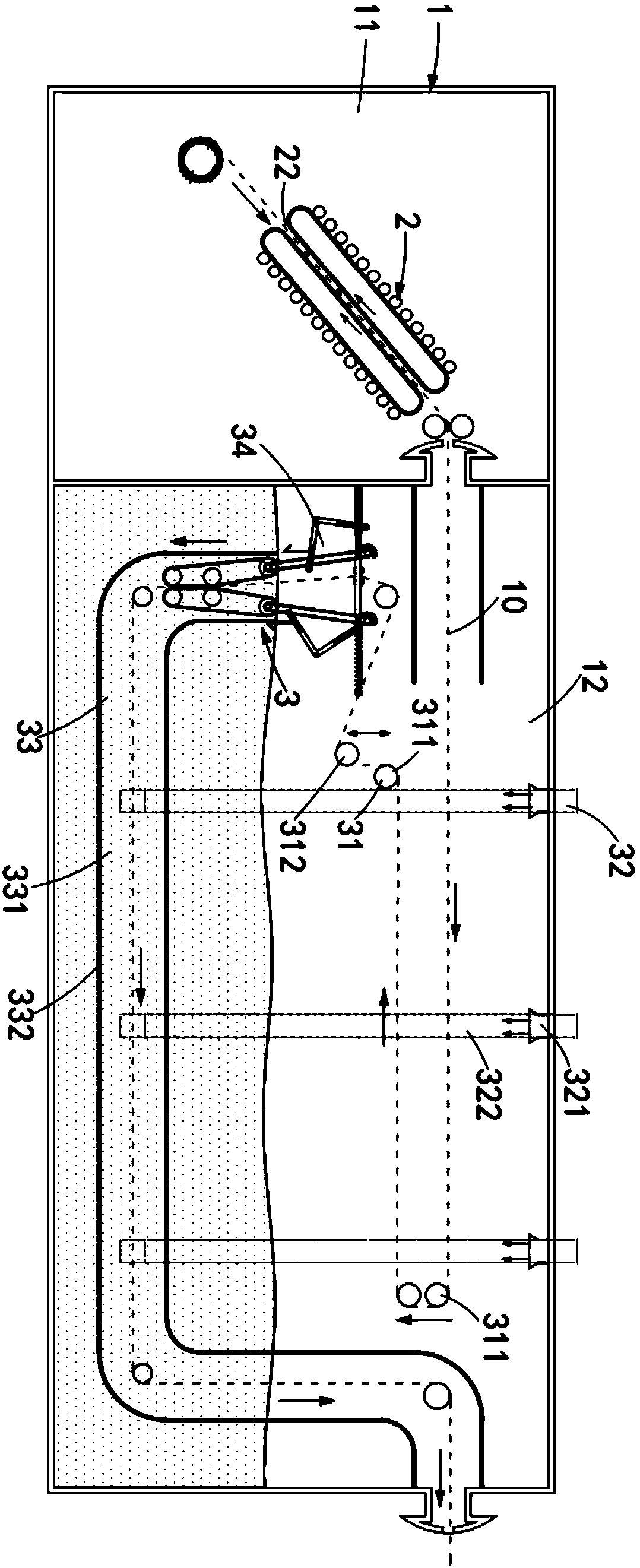

[0062] Such as figure 1 As shown, the dyeing and finishing system for plain polyester filament yarn-dyed fabrics includes a box body 1, which is divided into an electrostatic chamber 11 and a dyeing chamber 12. The fabric 10 is transported from the electrostatic chamber 11 to the dyeing chamber 12, and then dyed Room 12 output also includes:

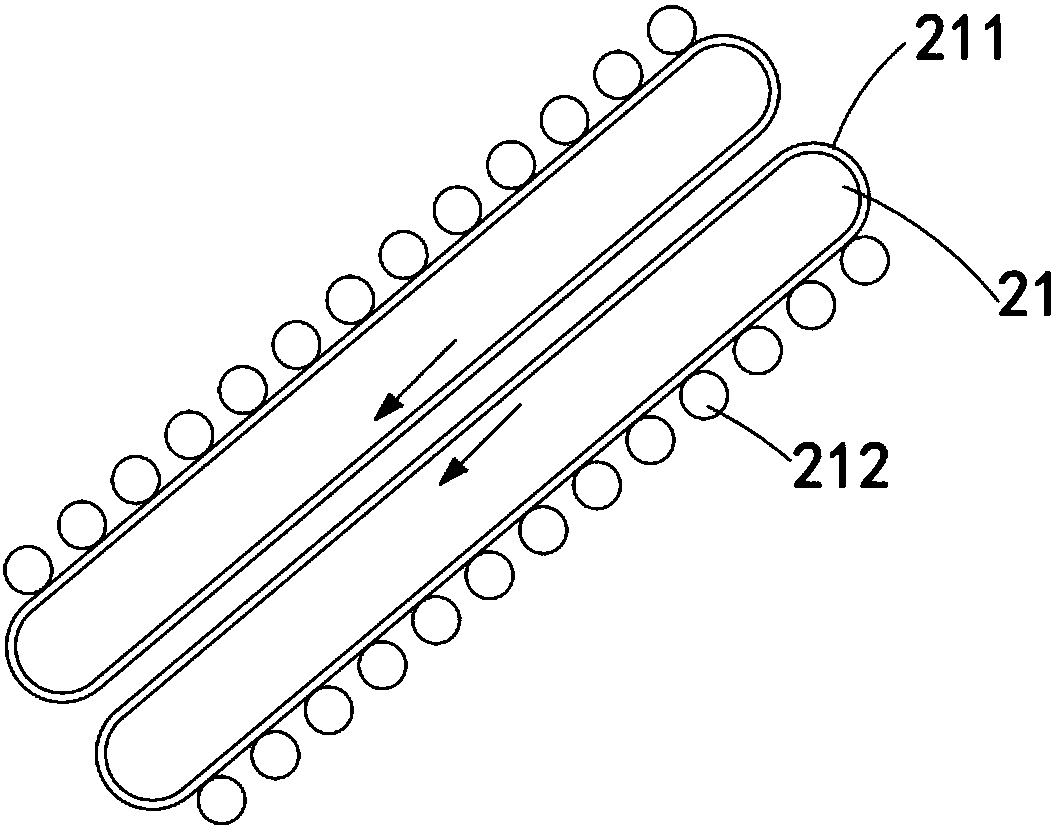

[0063] An electrostatic precipitating mechanism 2, which is arranged in the electrostatic chamber 11, and includes a symmetrical dedusting assembly 21 up and down. The middle of the electrostatic precipitating mechanism 2 forms a dedusting channel 22 for the fabric 10 to pass through; and

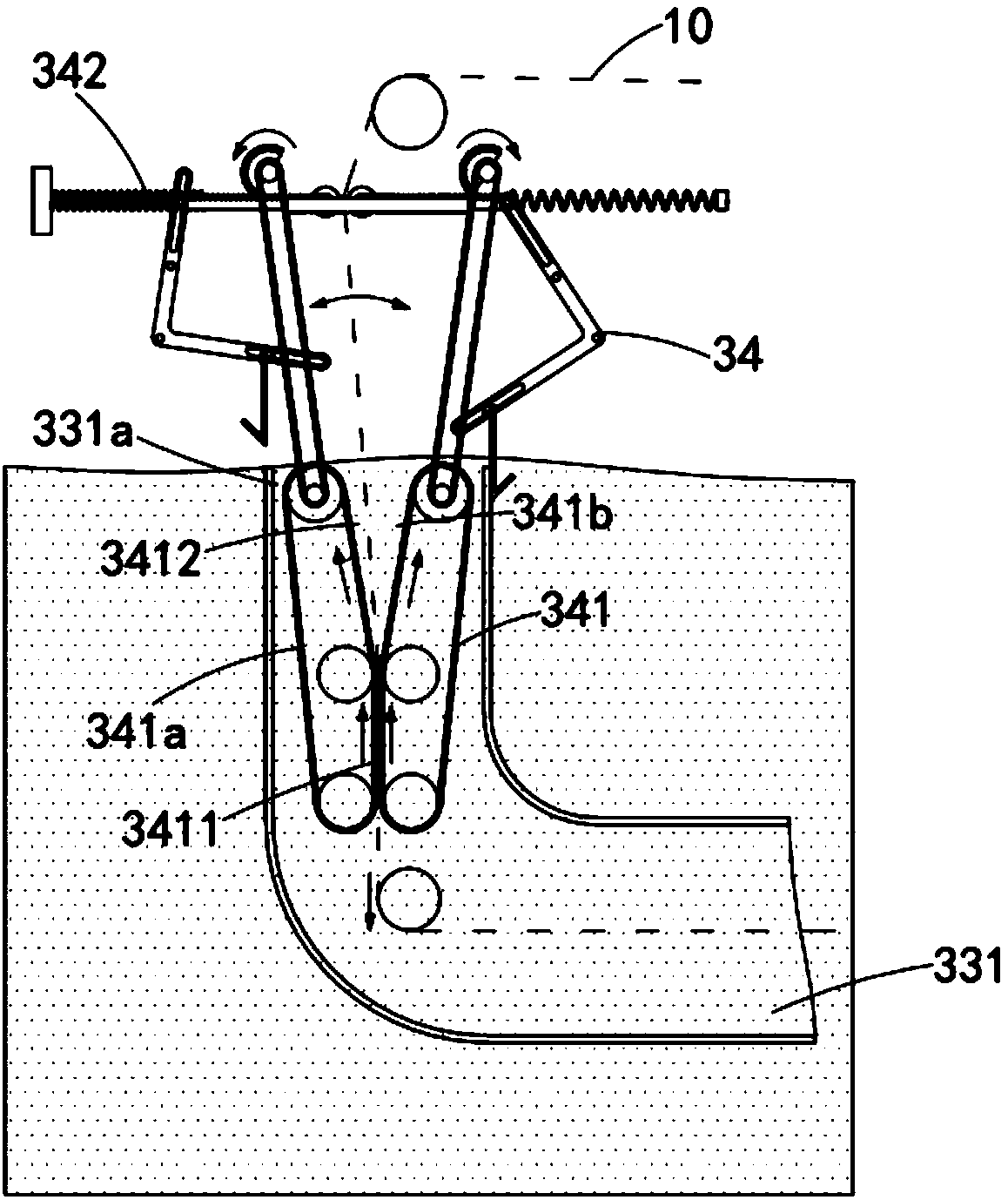

[0064] The dyeing mechanism 3, the dyeing mechanism 3 is arranged in the dyeing chamber 12, and includes a guide assembly 31, a spray dye assembly 32, a dip dye assembly 33, and a decontamination assembly 34. The guide assembly 31 is transported along the fabric 10 Direction setting, the spray dyeing assembly 32 is arranged at the top of the dyeing chamber...

Embodiment approach

[0072] Such as figure 1 As shown, as a preferred embodiment, the guide assembly 31 includes:

[0073] A fixed cloth guide roller 311, a plurality of the fixed cloth guide rollers 311 are all arranged to rotate along the conveying direction of the fabric 10, which causes the fabric 10 to be conveyed in a hex shape; and

[0074] The movable cloth guide roller 312 is arranged above the impregnation assembly 33 and is located on one side of the impurity removal assembly 34, which can move up and down with the tension of the fabric 10.

[0075] It should be noted that while the movable cloth guide roller 312 is provided to keep the fabric 10 under tension, the movable cloth guide roller 312 can be used to swing up and down to adjust the length of the fabric 10 so that the fabric 10 can swing horizontally.

[0076] Such as figure 1 As shown, as a preferred embodiment, the spray dye assembly 32 includes:

[0077] Nozzles 321, a number of the nozzles 321 are all arranged on the top of the dyein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com