Macro-zoom optical system

An optical system and macro technology, applied in the field of macro zoom optical system, can solve the problems that affect the user's sensory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

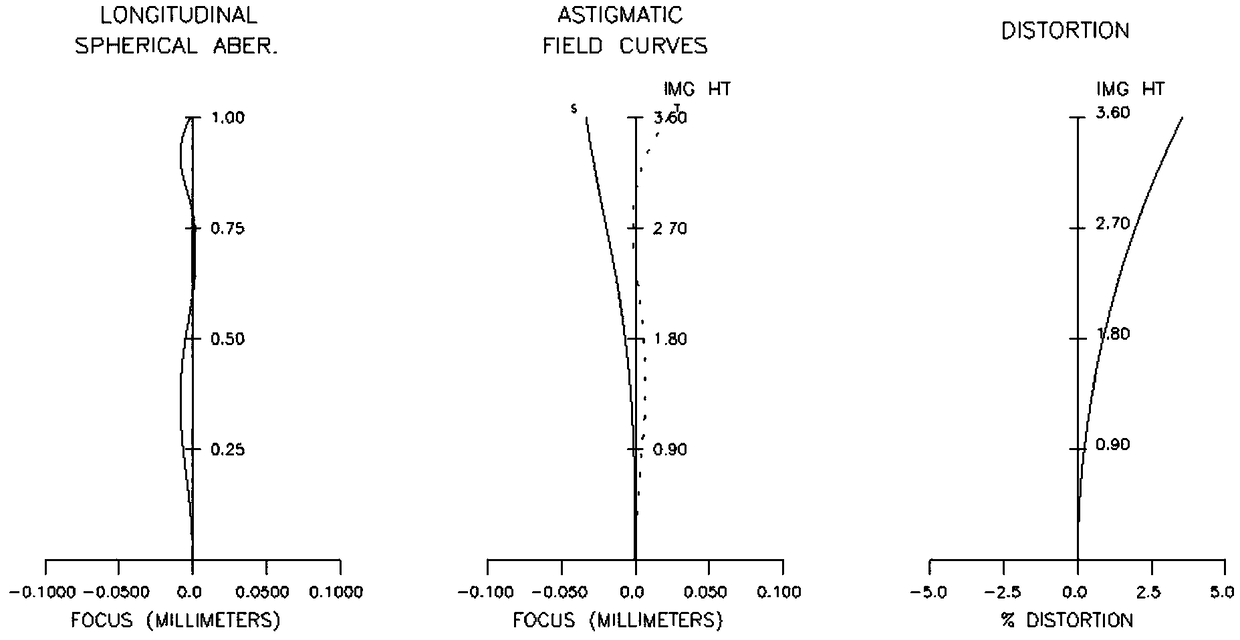

Embodiment 1

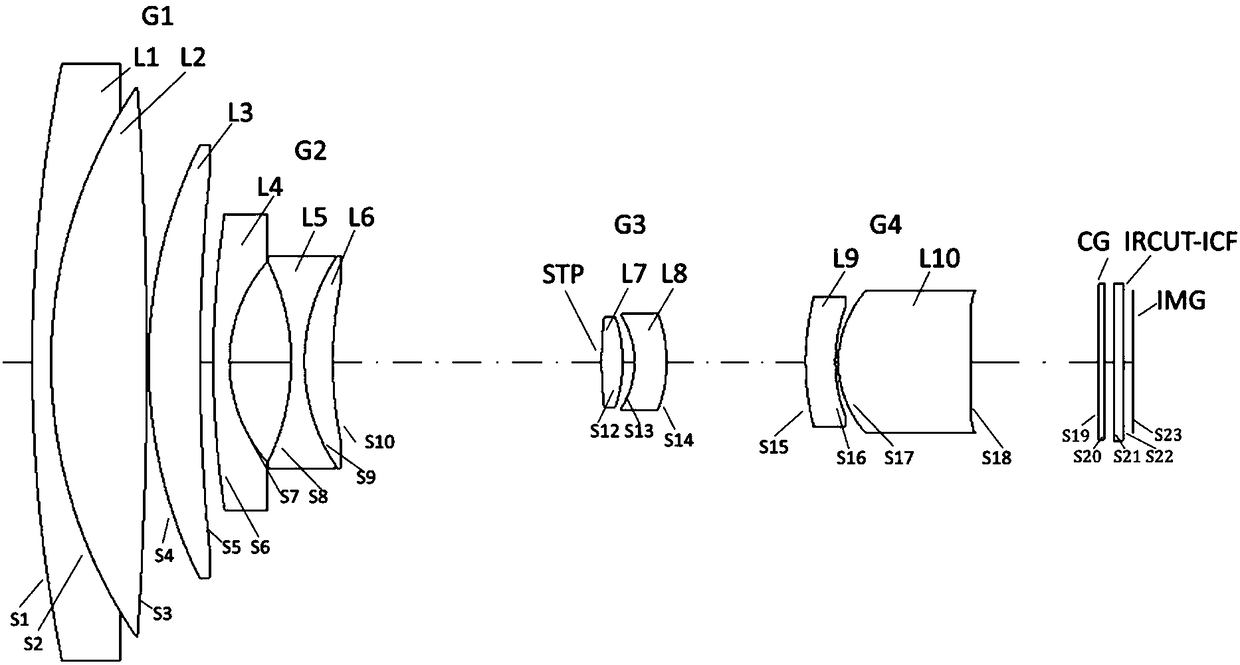

[0032] Such as figure 1 As shown, this embodiment sequentially includes from the object side to the image side: a first lens group G1 with positive refractive power, a second lens group G2 with negative refractive power, a third lens group G3 with positive refractive power, and The fourth lens group G4 with positive refractive power and the light receiving surface IMG, wherein: the first lens group and the third lens group are fixed groups, the second lens group is a zoom group, and the fourth lens group is a focus group.

[0033] A protective glass CG and an infrared cut filter IRCUT-ICF for filtering unnecessary light and stray light are arranged between the fourth lens group G4 and the sensor IMG.

[0034] The light receiving surface IMG is provided with solid-state imaging elements such as CCD and CMOS.

[0035] The first lens group G1 includes in order from the object side: a first lens L1 with positive refractive power, a second lens with negative refractive power L2, and a thi...

Embodiment 2

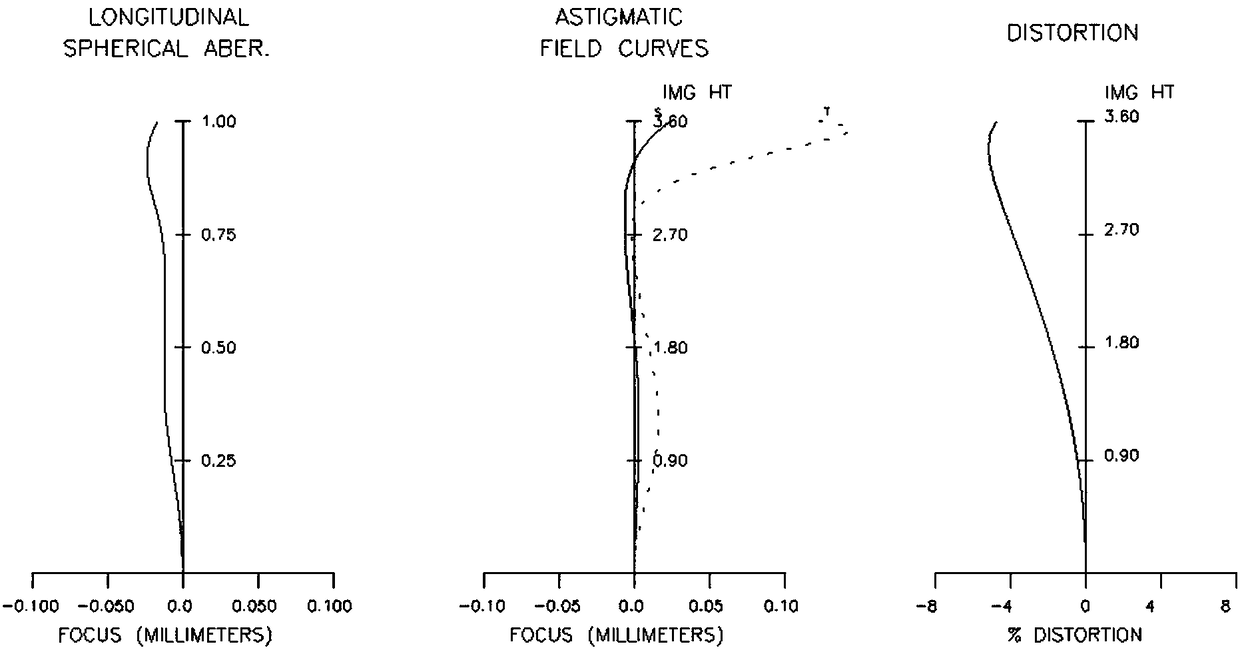

[0052] Such as Figure 4 As shown, compared with Embodiment 1, the first lens group G1 in this embodiment sequentially includes from the object side: a first lens L1 with positive refractive power, a second lens L2 with negative refractive power, and a positive refractive power A third lens L3 with a degree of power and a fourth lens L4 with positive refractive power, wherein the second lens L2 is cemented with the third lens L3.

[0053] The second lens group G2 includes in order from the object side: a fifth lens L5 with negative refractive power, a sixth lens L6 with negative refractive power, and a seventh lens L7 with positive refractive power.

[0054] The third lens group G3 includes, from the object side, an eighth lens L8 with positive refractive power and a ninth lens L9 with negative refractive power. The front surface of the eighth lens L8 is set as an aperture stop STP.

[0055] The fourth lens group G4 includes in order from the object side: a tenth lens L10 with negati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com