Carrying device with automatic feeding function for livestock cubs

A technology for automatic feeding and loading equipment, which is used in animal husbandry, animal houses, animal feeding devices, etc., and can solve problems such as food and water deterioration, sick cubs, and inability to automatically feed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

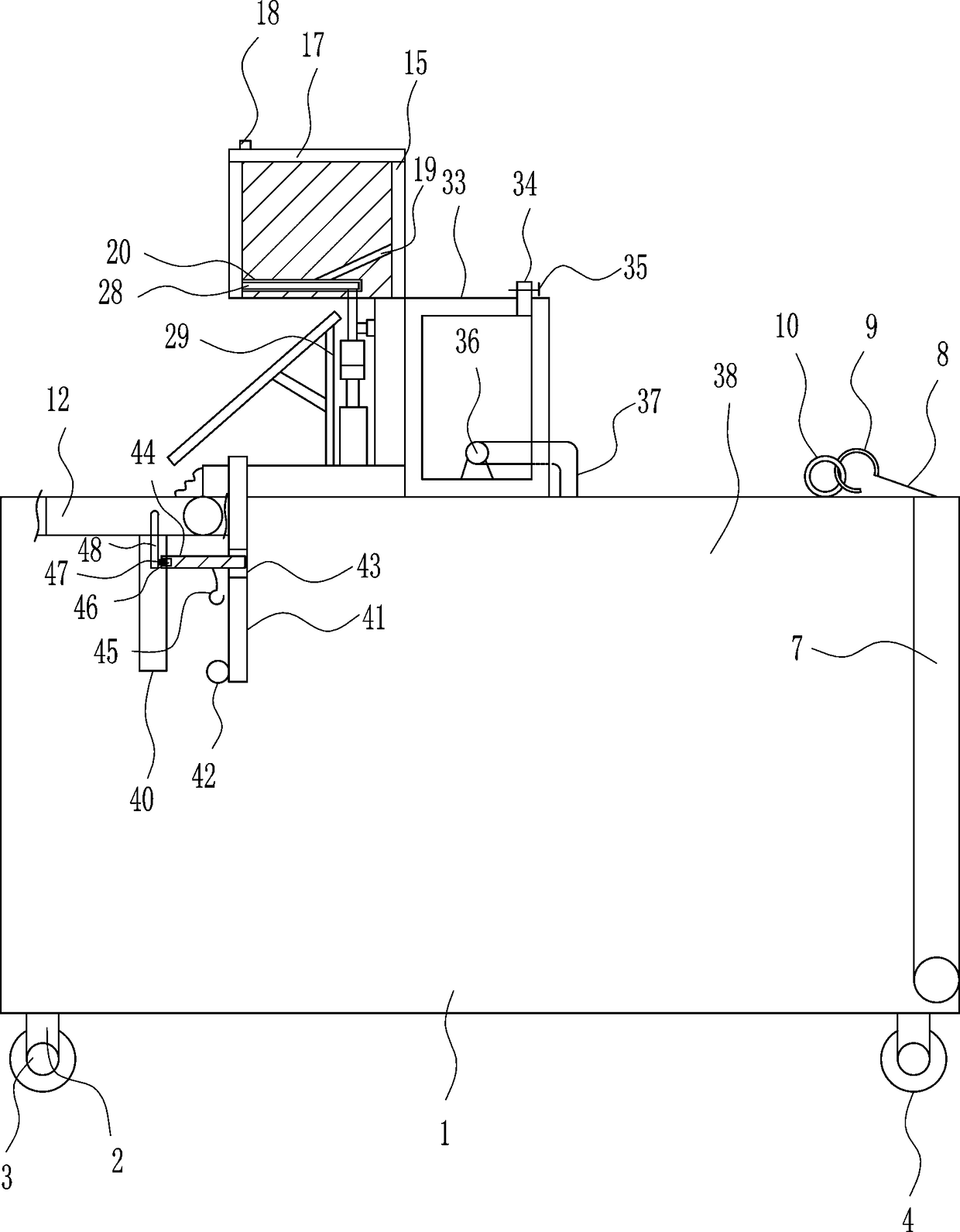

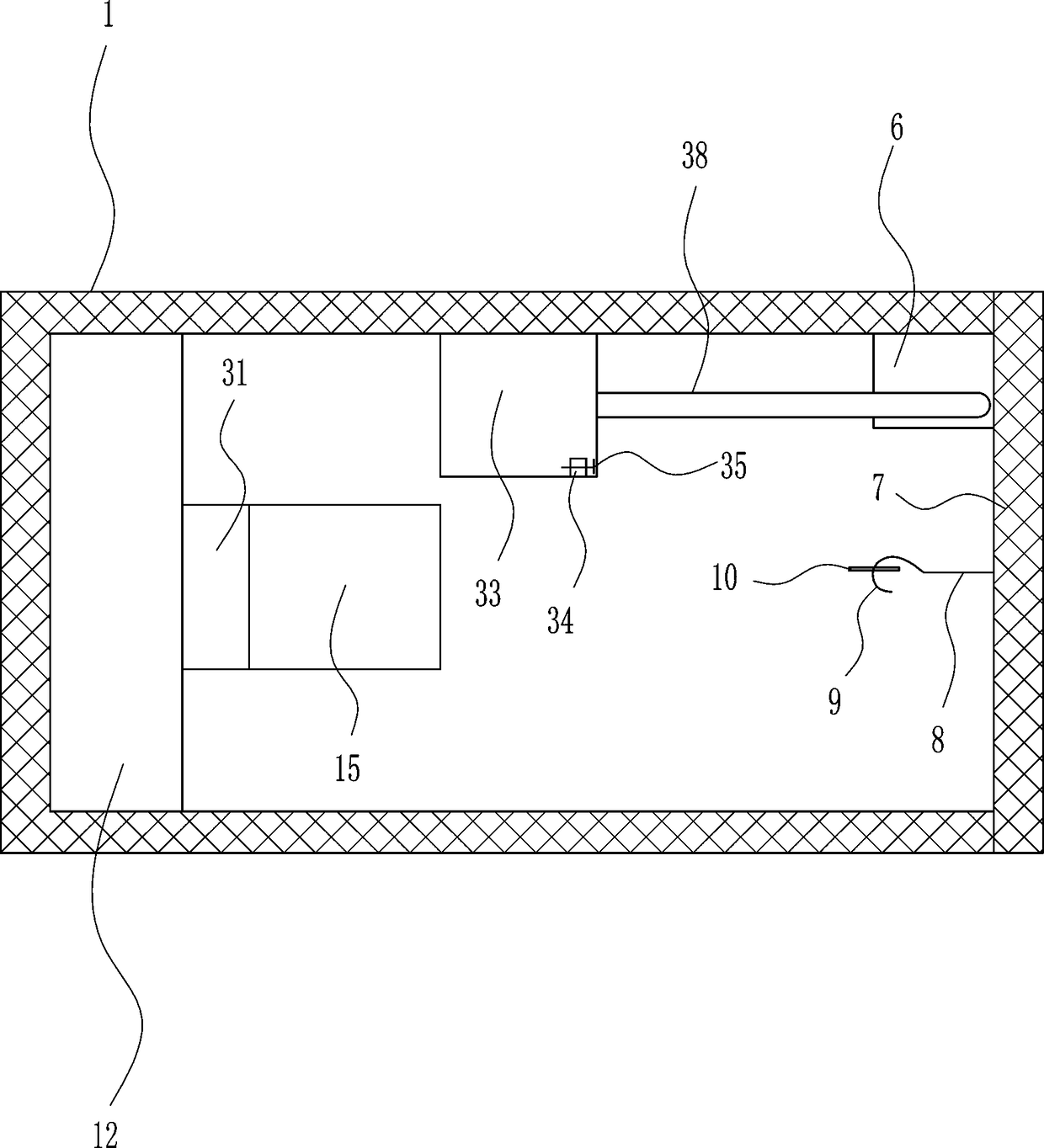

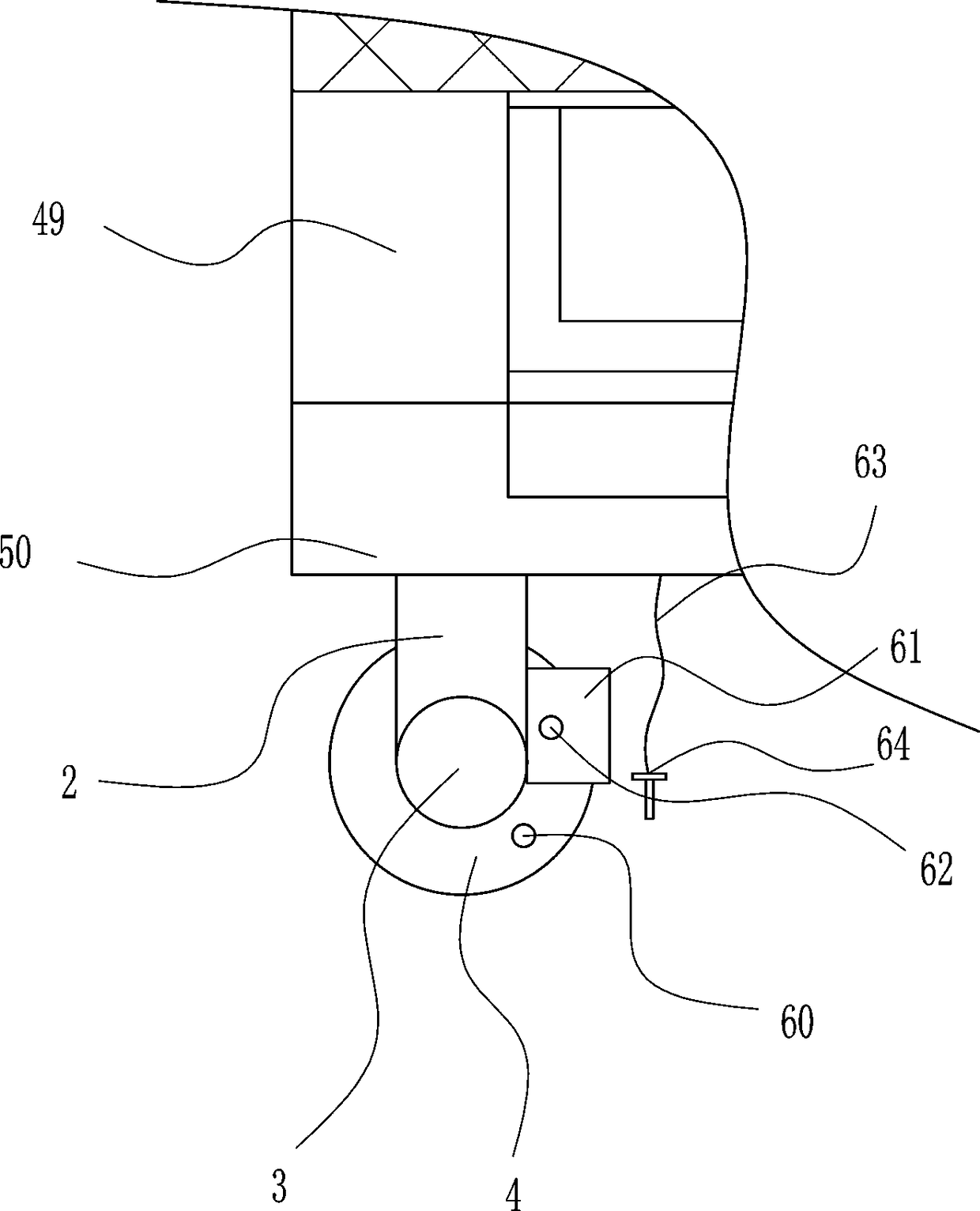

[0030] A loading device that can automatically feed food for the transportation of livestock cubs, such as Figure 1-7 As shown, it includes a net frame 1, a first bearing seat 2, a first rotating shaft 3, a wheel 4, a food basin 5, a drinking basin 6, a net plate 7, a first pull cord 8, a first hook 9, and a first hanging ring 10. The first hinge 11, the first cover 12, the mounting plate 13, the first fixing plate 14, the blanking box 15, the second hinge 16, the second cover 17, the handle 18, the first guide plate 19, Cylinder 21, the first triangular block 22, the first slide rail 23, the first slide block 24, the first spring 25, the moving rod 26, the second triangular block 27, the baffle plate 28, the support rod 29, the fixed rod 30, the second Guide plate 31, the second spring 32, water tank 33, water inlet pipe 34, valve 35, water pump 36, the first hard pipe 37, the second hard pipe 38 and water outlet pipe 39, screen frame 1 bottom left and right sides are arrang...

Embodiment 2

[0032] A loading device that can automatically feed food for the transportation of livestock cubs, such as Figure 1-7 As shown, it includes a net frame 1, a first bearing seat 2, a first rotating shaft 3, a wheel 4, a food basin 5, a drinking basin 6, a net plate 7, a first pull cord 8, a first hook 9, and a first hanging ring 10. The first hinge 11, the first cover 12, the mounting plate 13, the first fixing plate 14, the blanking box 15, the second hinge 16, the second cover 17, the handle 18, the first guide plate 19, Cylinder 21, the first triangular block 22, the first slide rail 23, the first slide block 24, the first spring 25, the moving rod 26, the second triangular block 27, the baffle plate 28, the support rod 29, the fixed rod 30, the second Guide plate 31, the second spring 32, water tank 33, water inlet pipe 34, valve 35, water pump 36, the first hard pipe 37, the second hard pipe 38 and water outlet pipe 39, screen frame 1 bottom left and right sides are arrang...

Embodiment 3

[0035] A loading device that can automatically feed food for the transportation of livestock cubs, such as Figure 1-7As shown, it includes a net frame 1, a first bearing seat 2, a first rotating shaft 3, a wheel 4, a food basin 5, a drinking basin 6, a net plate 7, a first pull cord 8, a first hook 9, and a first hanging ring 10. The first hinge 11, the first cover 12, the mounting plate 13, the first fixing plate 14, the blanking box 15, the second hinge 16, the second cover 17, the handle 18, the first guide plate 19, Cylinder 21, the first triangular block 22, the first slide rail 23, the first slide block 24, the first spring 25, the moving rod 26, the second triangular block 27, the baffle plate 28, the support rod 29, the fixed rod 30, the second Guide plate 31, the second spring 32, water tank 33, water inlet pipe 34, valve 35, water pump 36, the first hard pipe 37, the second hard pipe 38 and water outlet pipe 39, screen frame 1 bottom left and right sides are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com