Novel feed feeding device

A feed and equipment technology, applied in the field of aquaculture, can solve the problems of low efficiency, unsuitable for spreading feed in stocking places, time-consuming and labor-intensive, etc., and achieves the effects of convenient movement and handling, high operation stability, and improved practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

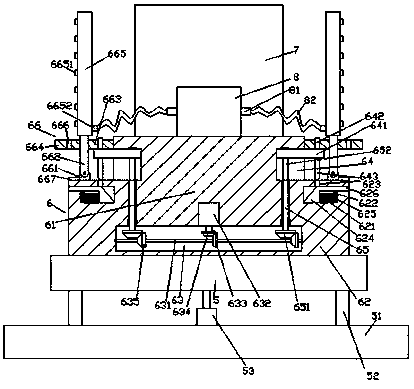

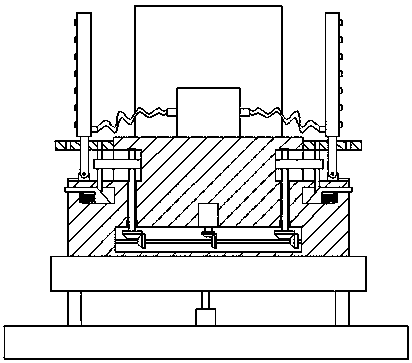

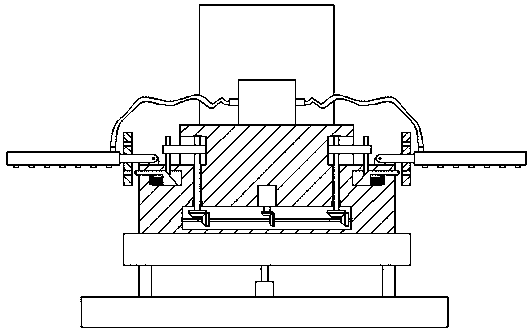

[0023] Such as Figure 1-Figure 6 As shown, a new type of feed feeding equipment of the present invention includes a base 5 and a feeding device 6 fixed on the top of the base 5, and the feeding device 6 consists of a first machine part 61 and is arranged on the second The first machine part 61 is composed of the second machine part 62 on the left and right sides. The first machine part 61 is provided with a first chamber 63 extending left and right. Connecting shaft 631, the inner top surface of the first chamber 63 is provided with a driving device 632, and the bottom of the driving device 632 is connected with a first cone wheel 634 protruding into the first chamber 63. The right end of a cone wheel 634 is wedgingly connected with a second cone wheel 633 fixedly connected to the outer surface of the first adapter shaft 631, and the left and right sides of the first machine part 61 above the first chamber 63 There are guide grooves 64 inside. The guide grooves 64 on the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com