Equipment for processing ink

A technology of equipment and ink, which is applied to mixers with rotating stirring devices, mixers, shaking/oscillating/vibrating mixers, etc., can solve problems such as short service life, damage to stirring paddles, displacement, etc., to avoid shaking up and down, The effect of ensuring firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

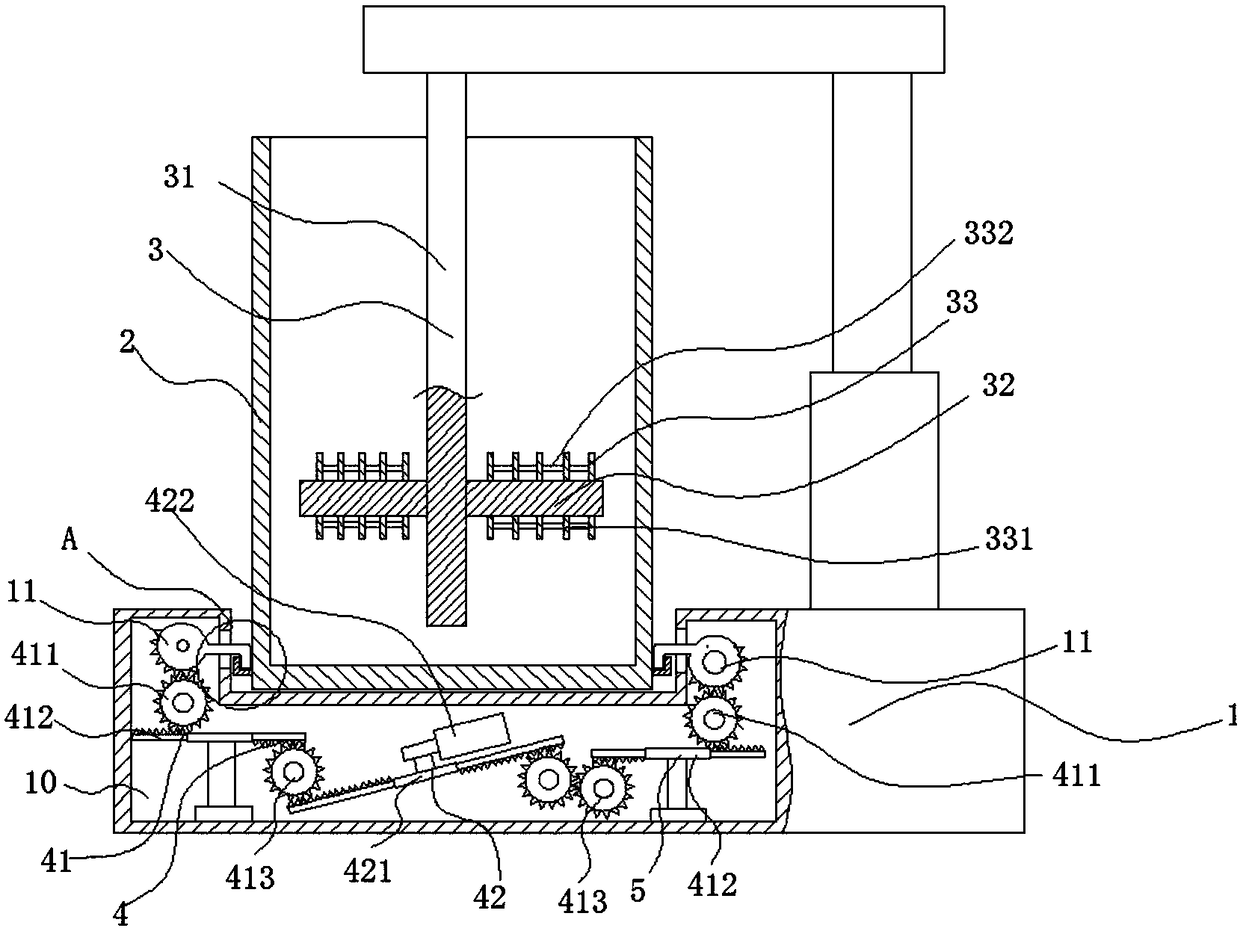

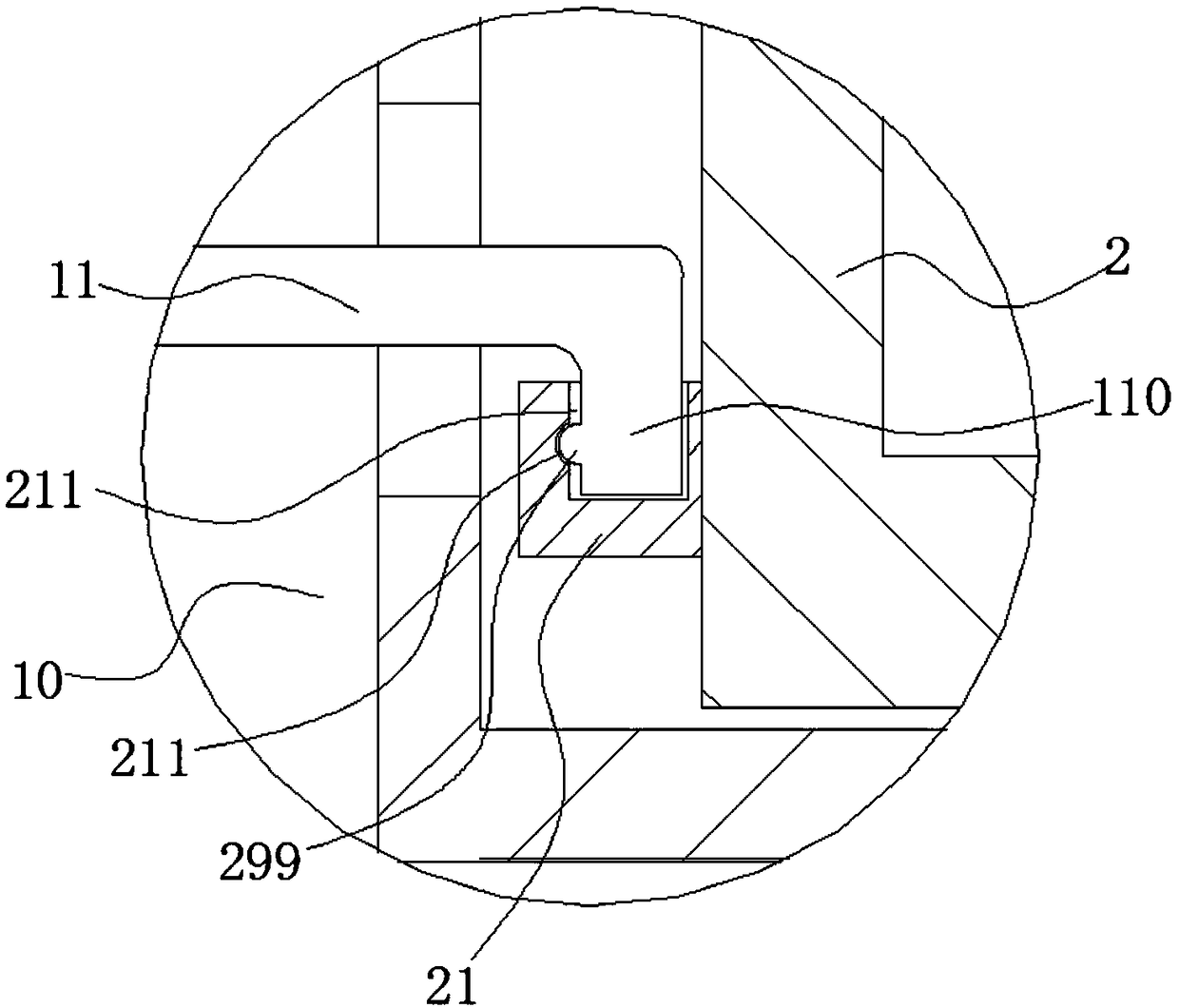

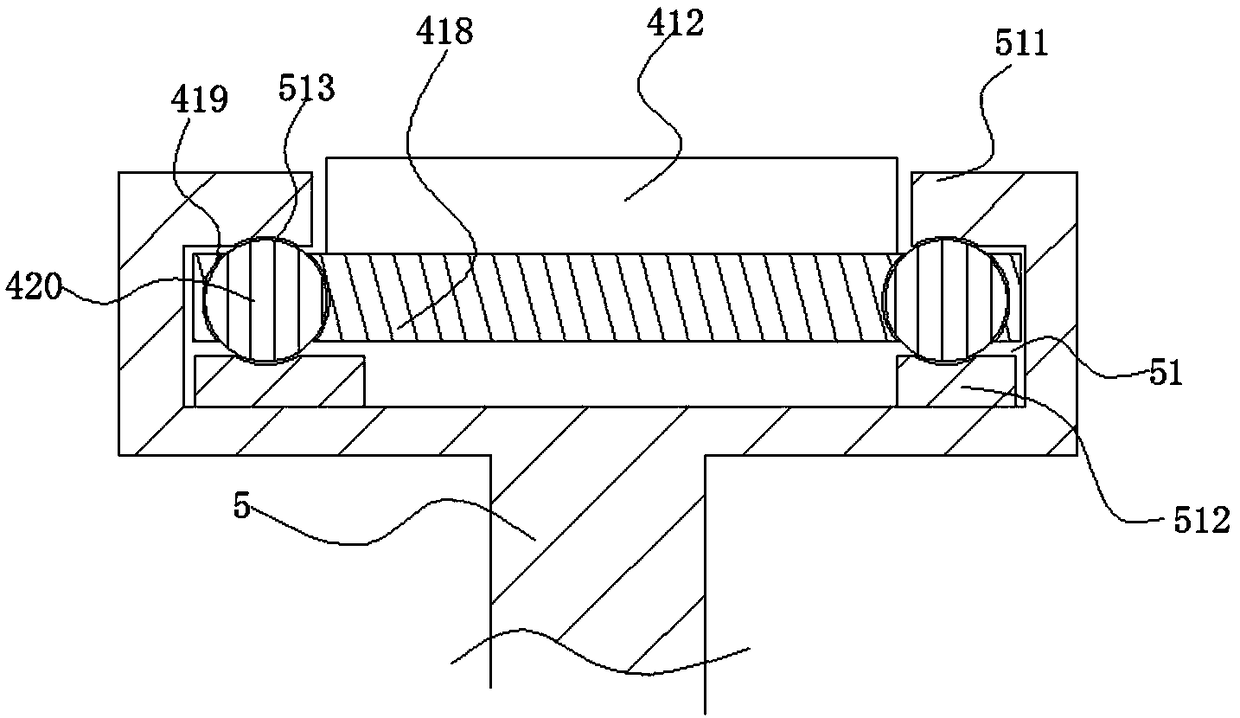

[0017] Such as figure 1 As shown, a kind of equipment for processing ink comprises a base 1, a liquid holding part 2 and a stirring part 3, the base 1 is a metal plate, and the liquid holding part 2 is a metal barrel; The outer wall of the part 2 is provided with a fastening part 21, and the fastening part 21 is a circle of metal rings arranged at the lower part of the liquid containing part 2, and a fastening groove 211 is provided on the fastening part 21. The fixing groove 211 is a concave ring formed by the upper end of the fixing part 21 being depressed downward; a placement cavity 10 is provided on the base 1, and the liquid holding part 2 is placed in the placement cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com