Vehicle body parts manufacturing method

A manufacturing method and component technology, applied in the field of manufacturing high-strength car body parts by hot stamping, to achieve the effect of preventing deviation and free design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below with reference to the accompanying drawings of the present invention. For the convenience of description, the same constituent elements or components in the drawings use the same reference signs as much as possible.

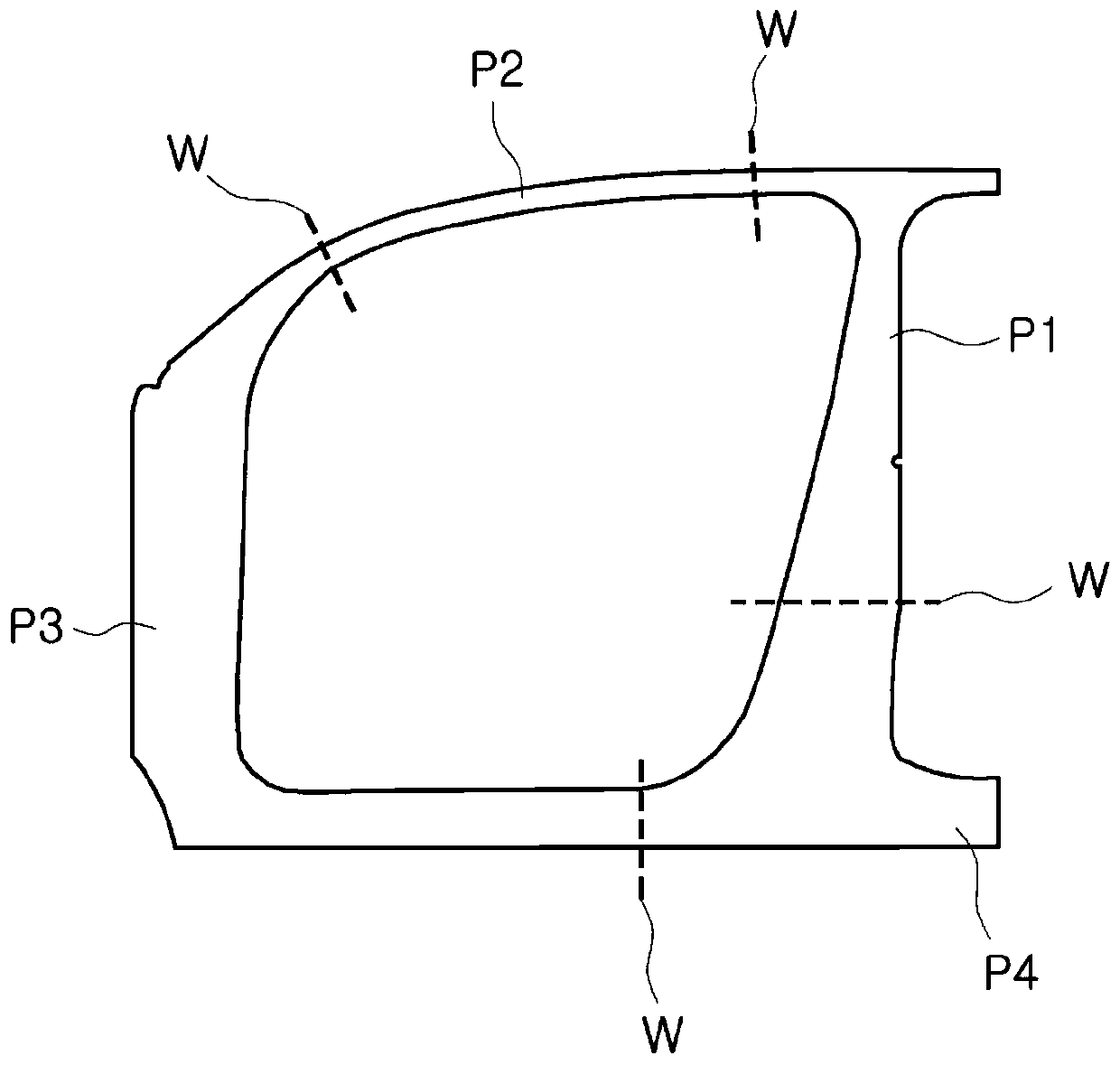

[0039] refer to Figure 3 to Figure 4d , the method of manufacturing a vehicle body member according to the embodiment will be described.

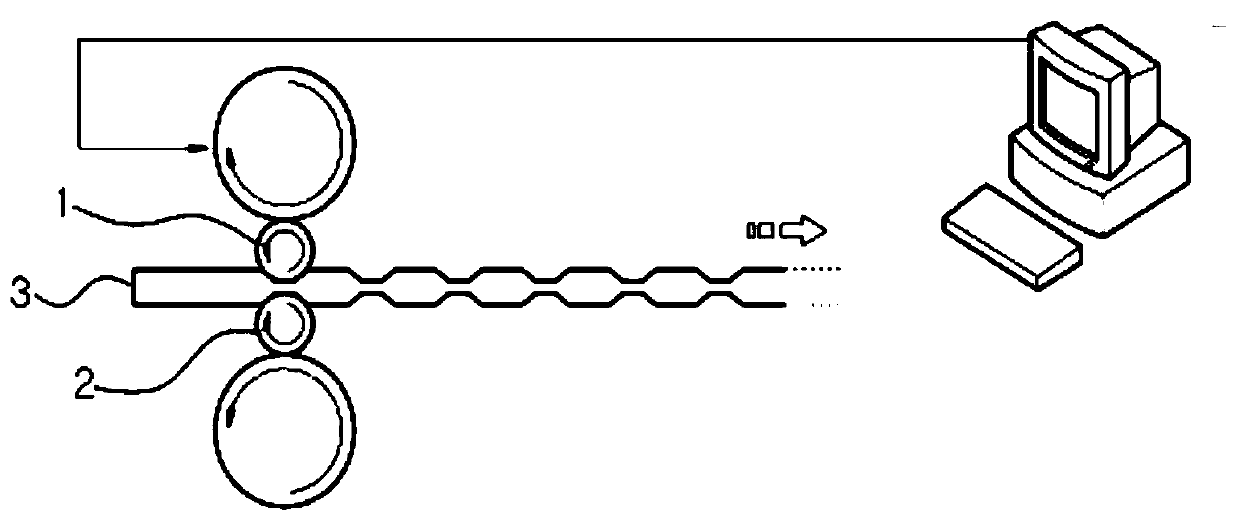

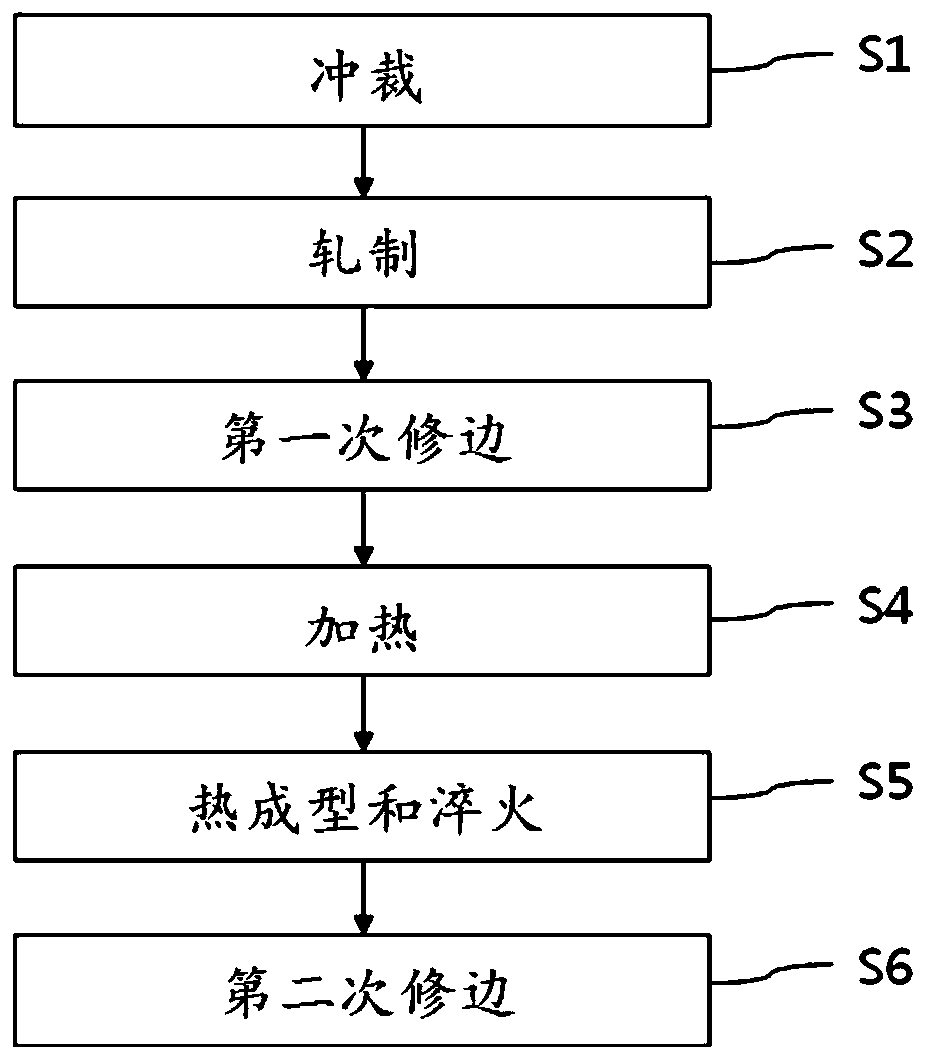

[0040] Such as image 3 As shown, according to the embodiment, the car body parts can be punched (S1), rolled (S2), trimmed for the first time (S3), heated (S4), thermoformed and cooled (S5), trimmed for the second time edge (S6) and manufacture. As a material of the slab 10, an aluminized steel sheet for hot stamping can be used. The aluminum coating of the steel sheet may include an outer aluminum or aluminum alloy layer and an inner intermetallic alloy layer.

[0041] Punching process (S1)

[0042] Such as Figure 4aAs shown, for stamping, aluminized s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com