Multi-objective optimization method for thickness of anti-collision beam of automobile composite bumper

A multi-objective optimization and composite material technology, which is applied in the multi-objective optimization field of the thickness of the automobile composite bumper anti-collision beam, can solve the problems of no approximate model, deviation of optimization results, inaccurate model optimization, etc., to shorten the time and Cost, good accuracy, global improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0040] The invention provides a multi-objective optimization method for the thickness of an automobile composite bumper anti-collision beam, and the specific process is as follows:

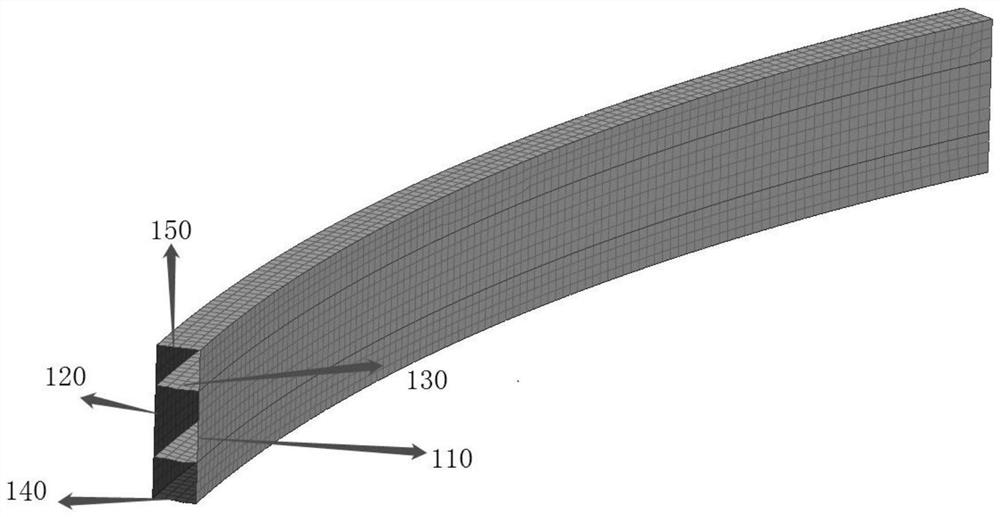

[0041] Such as figure 1 As shown, set the design variable x 1 represents the thickness of the anti-collision beam rear plate 110, x 2 represents the thickness of the front panel 120 of the anti-collision beam, x 3 Represents the thickness of the anti-collision beam rib 130, x 4 Represents the thickness of the lower plate 140 of the anti-collision beam, x 5 Represents the thickness of the upper plate 150 of the anti-collision beam, and defines the thickness of the upper and lower plates to be the same; the design variable adopts a discrete value method, and the value interval is 0.5.

[0042]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com