A kind of preparation method of thermal insulation container with good airtightness and thermal insulation container prepared thereof

A thermal insulation container and air tightness technology, which is applied in the field of thermal insulation containers and vacuum thermal insulation containers, can solve the problem of the lack of thermal insulation of vacuum thermal insulation containers, poor fusion and adhesion between glass glue and the main body of the container, and shortened service life of vacuum thermal insulation containers, etc. problem, to achieve the effect of fewer processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

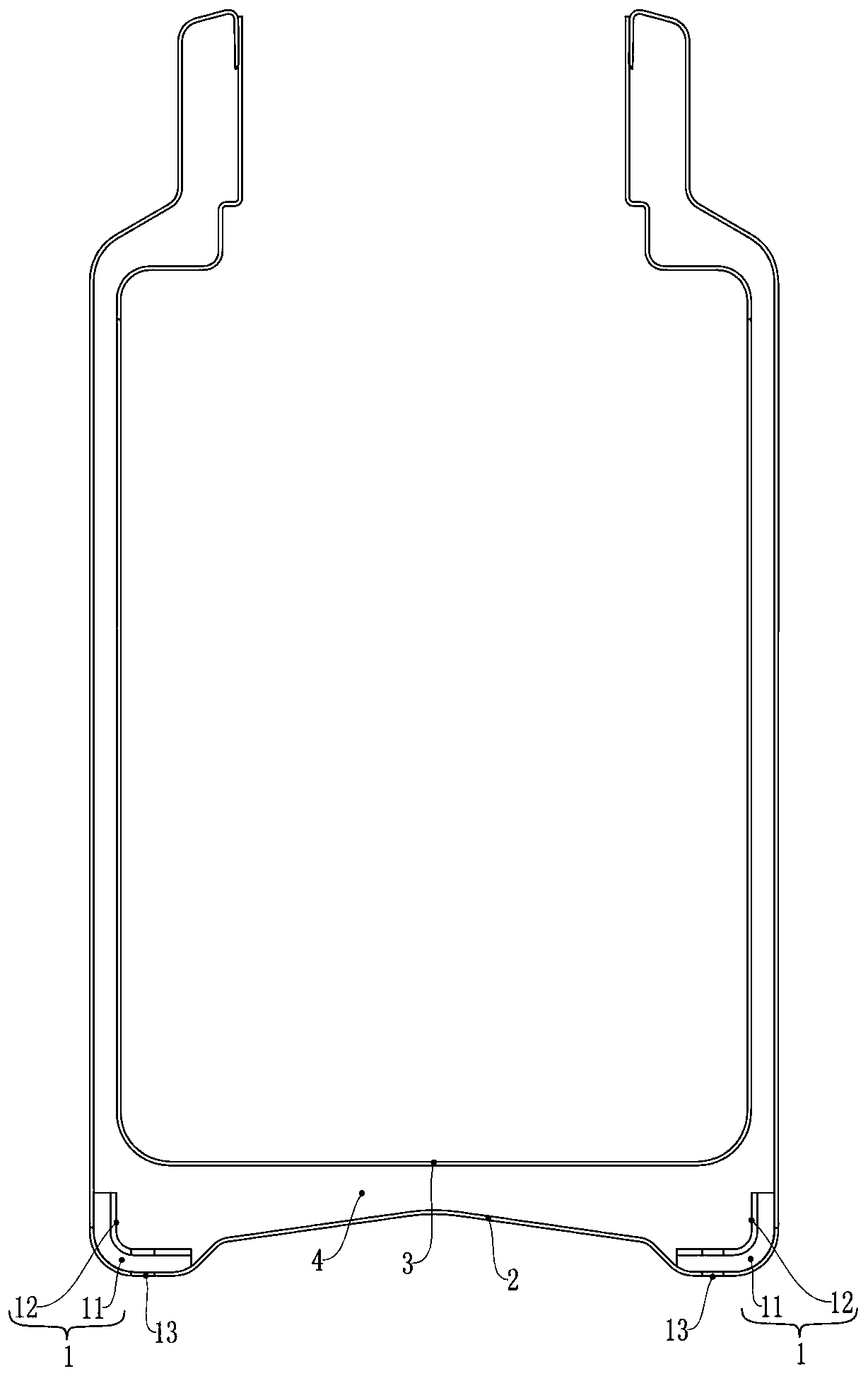

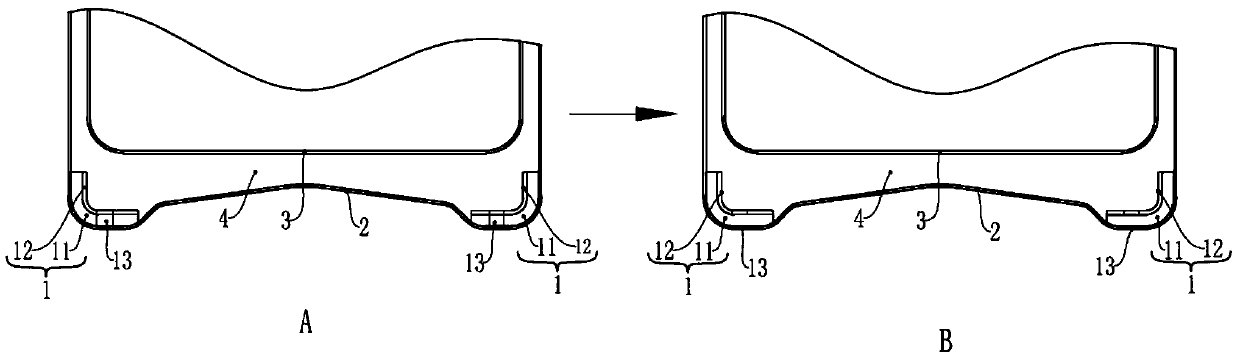

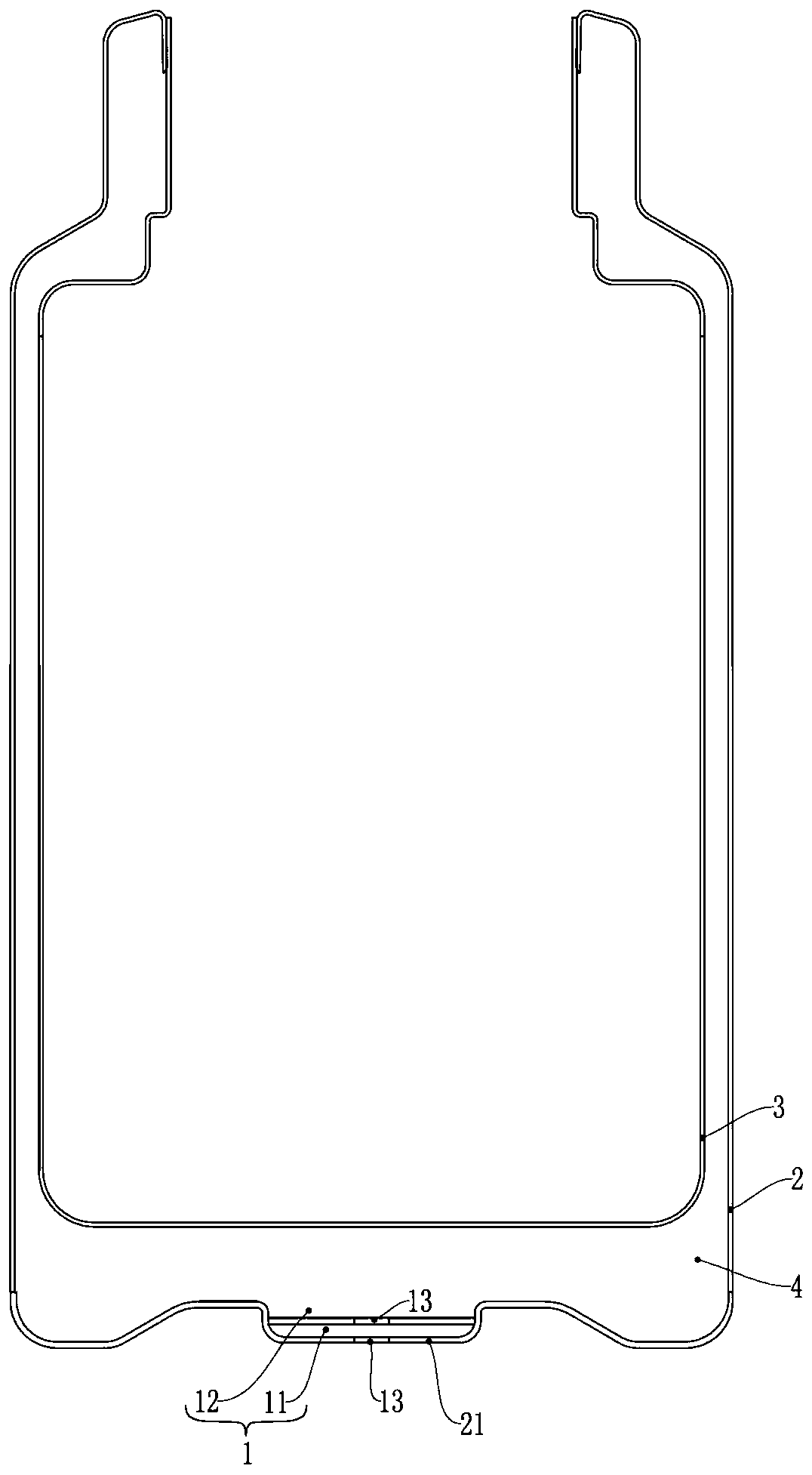

[0055] The good air-tight insulation container preparation method of the present embodiment, as figure 1 As shown, the heat preservation container is a heat preservation container formed by vacuumizing between the outer shell 2 and the inner shell 3 made of metal, and a sealed vacuum heat preservation cavity 4 is formed between the outer shell 2 and the inner shell 3, comprising the following steps :

[0056] Step A, prepare the auxiliary part 1, the auxiliary part 1 is formed by stacking the low-temperature sealing layer 11 and the high-temperature covering layer 12 and welding each other, and the low-temperature sealing layer 11 is made of metal that will melt at the melting temperature, so The high-temperature covering layer 12 is made of a metal that does not melt at the melting temperature;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com