Separated rubber water tank device

A separate and water tank technology, which is applied in basic structure testing, construction, basic structure engineering, etc., can solve problems such as low efficiency, pollute the environment, and low cost, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

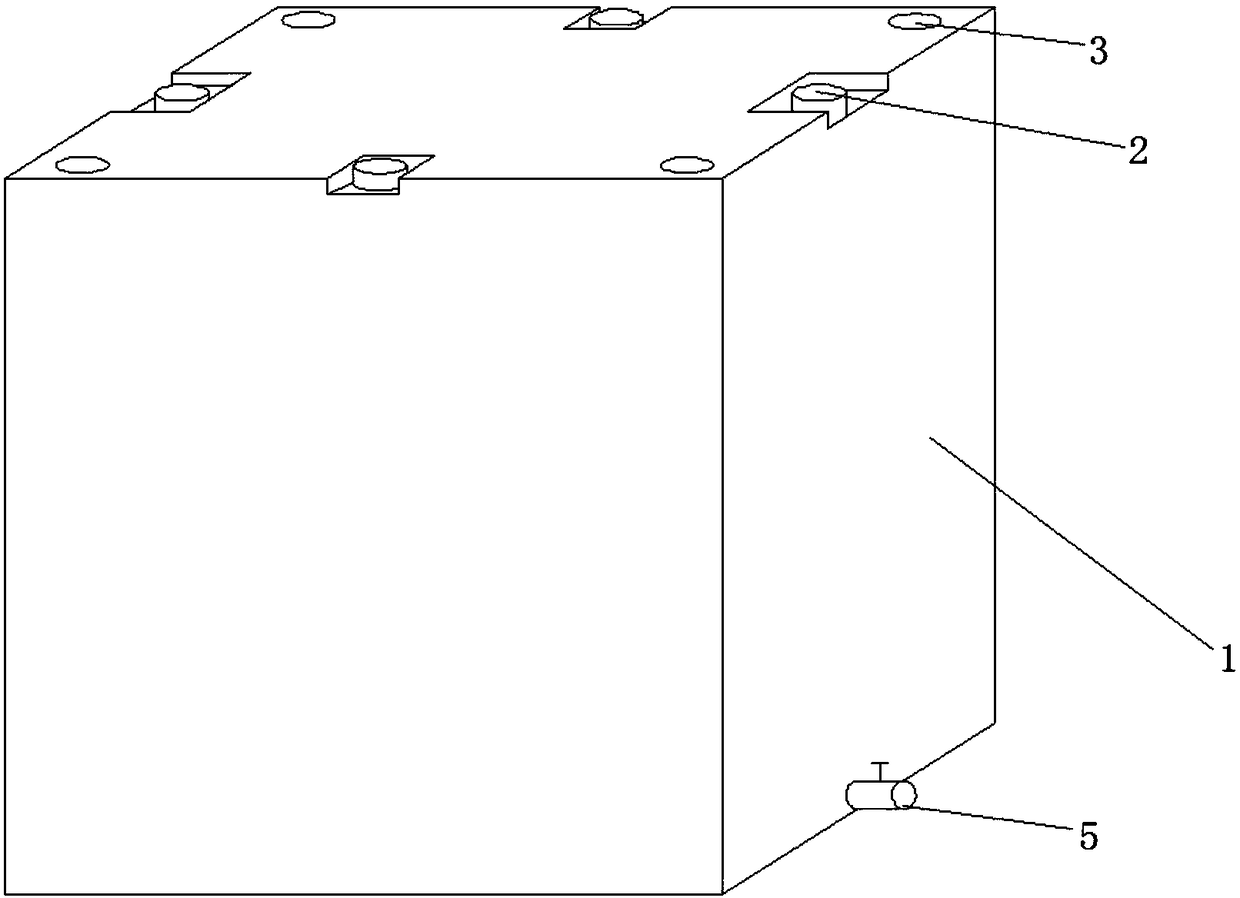

[0030] As mentioned above, the present invention has carried out pile foundation static load test in Dachuan Baijin City, Baiyun District, Guiyang, and the steps are as follows:

[0031] 1) Build a 10m×10m bearing platform (load platform) on the ground of the foundation pile. The center of the platform is located at the center of the pile, and the surroundings of the platform are balanced and supported. Jacks, pressure and displacement sensors are placed at the center, and instruments are connected.

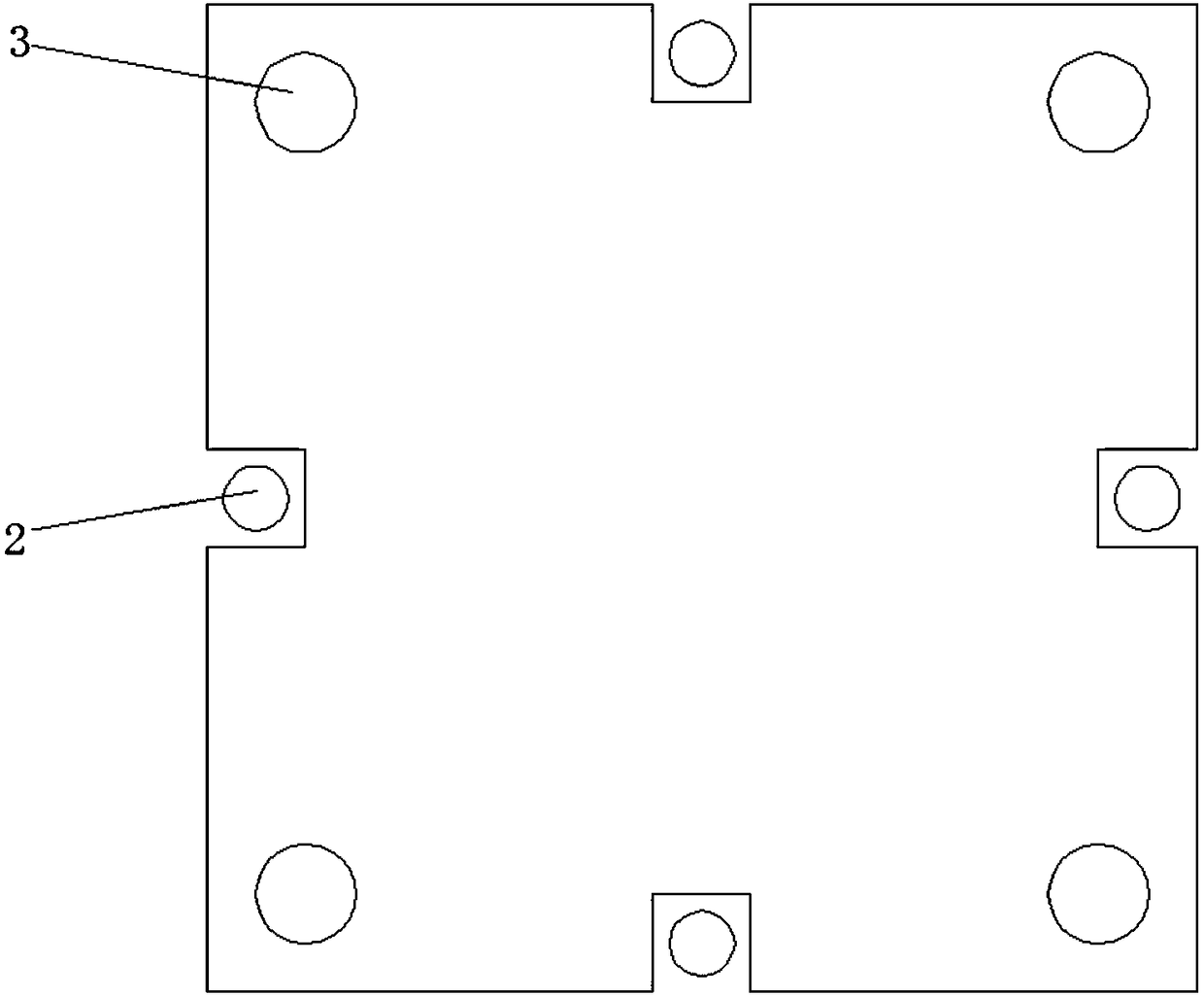

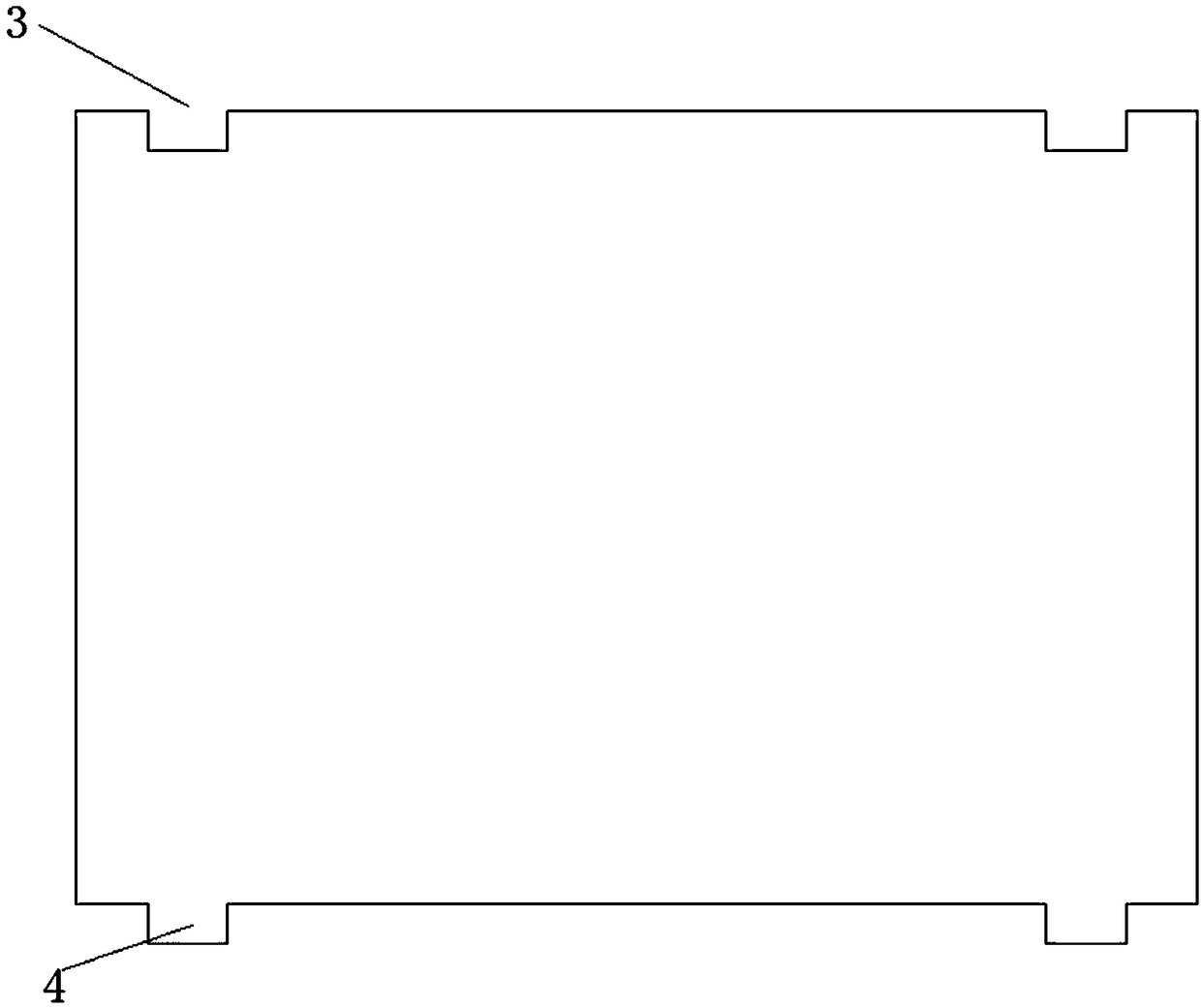

[0032] 2) According to the designed maximum load weight, arrange the corresponding number of water tanks 1 on the platform, arrange them symmetrically with the jack as the center on the plane, and connect the water tanks 1 at the same time.

[0033] 3) After arranging the water tanks 1 of one layer, inject water until the water tanks 1 of the same layer are completely filled, then install and connect the water tanks 1 on the upper layer, and fill them with water.

[0034] 4) When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com