Counter-force support for anchor rod drawing test and use method thereof

A pull-out test and reaction force bearing technology, applied in the bolt pull-out test and reaction force bearing field, can solve the problems of unbalanced force, irregularity, eccentric tension and so on, and achieve flexible use, wide application, Actionable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings.

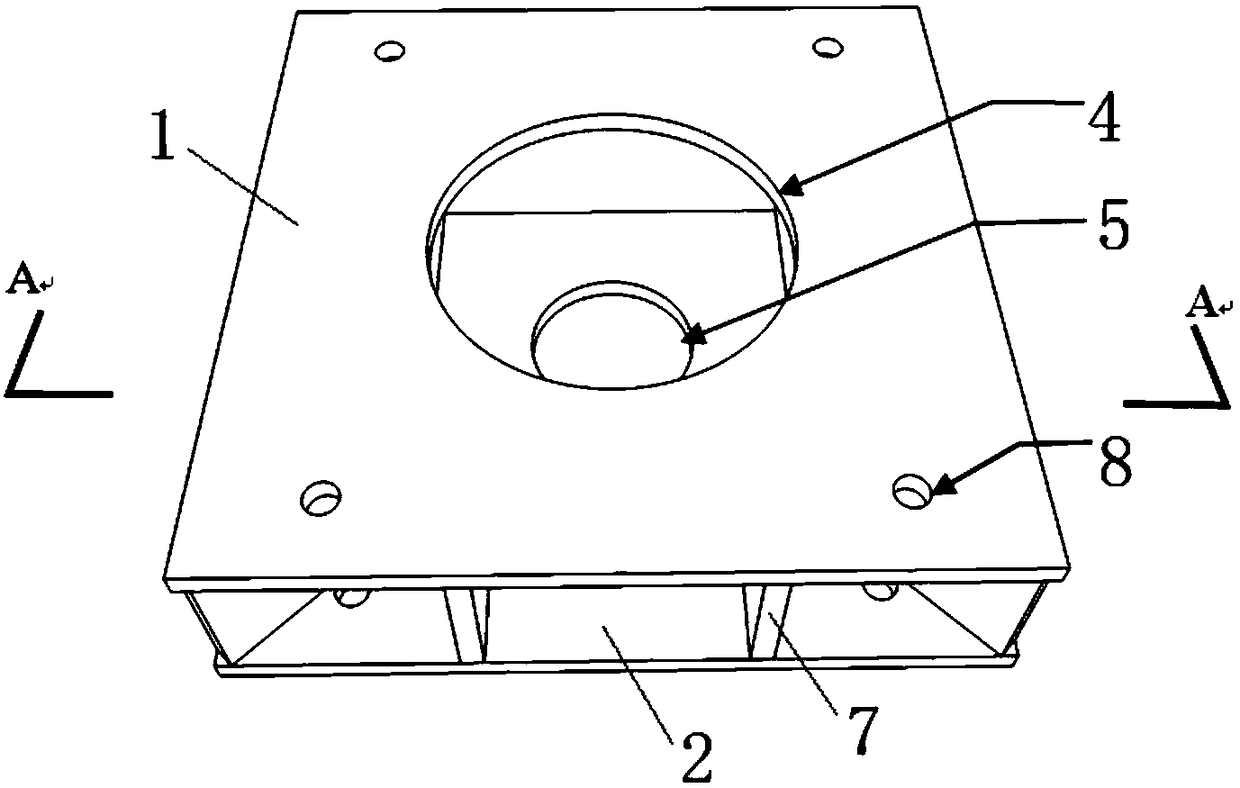

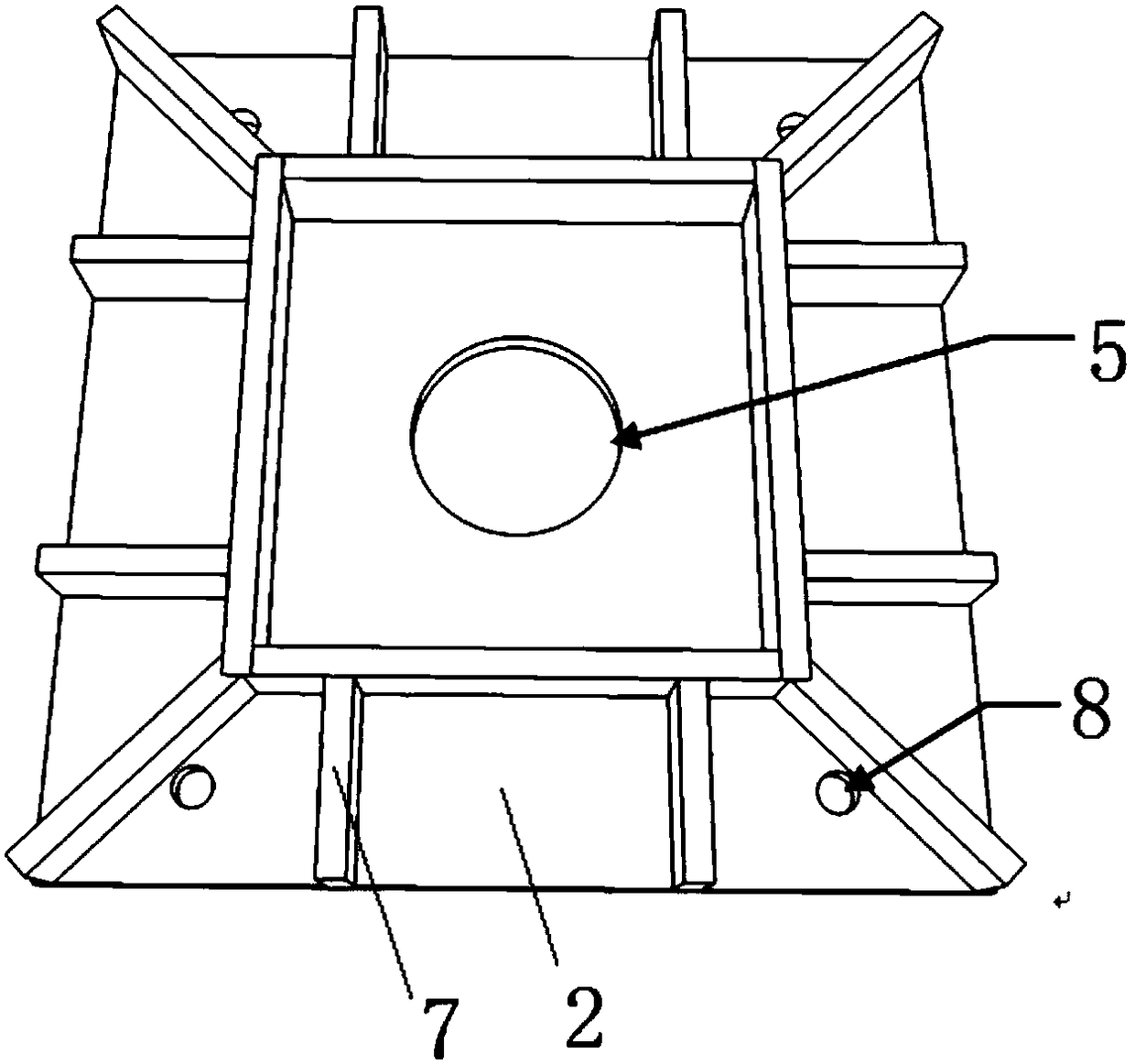

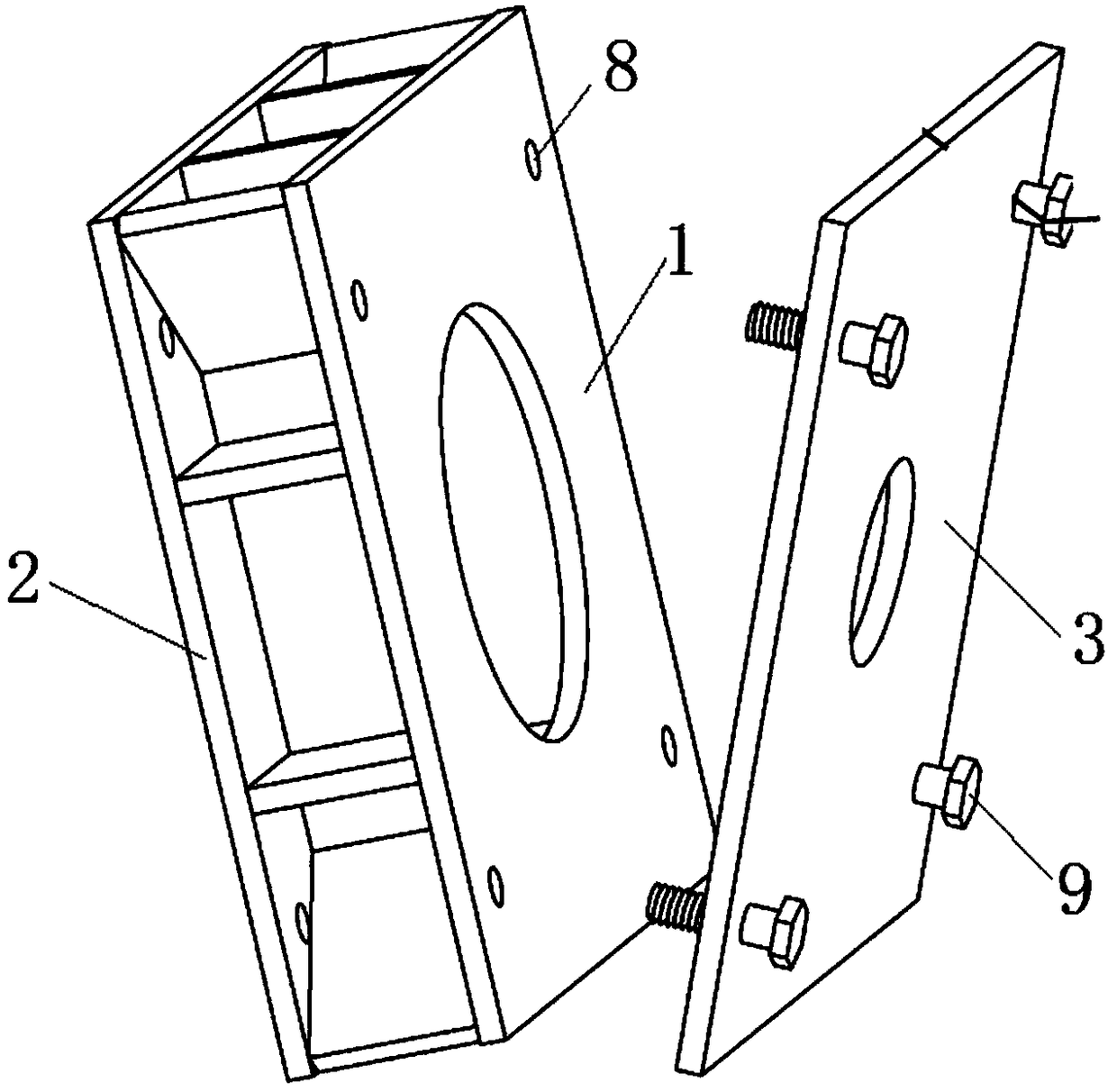

[0034] see figure 1 , figure 2 and image 3 , the novel reaction force bearing used for anchor pullout test of the present invention, comprises reaction backing plate and auxiliary backing plate.

[0035] Wherein, the reaction backing plate includes two identical first steel plates 1 and second steel plates 2, the first steel plates 1 and the second steel plates 2 are connected by a plurality of steel plates 7, and the two ends of each steel plate 7 are respectively welded on On the first steel plate 1 and the second steel plate 2, the height of the steel sheet 7 is 10 cm. The steel sheet 7 is made of the same material as the first steel plate 1 . The center of the first steel plate 1 is provided with the first circular hole 4, and the center of the second steel plate 2 is provided with the second circular hole 5, and the diameter of the first circular hole 4 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com