Collecting device for monitoring whether construction site dust reaches standards or not

A technology for collecting devices and dust, which can be used in measuring devices, analysis of suspensions and porous materials, instruments, etc., and can solve problems such as poor detection results and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

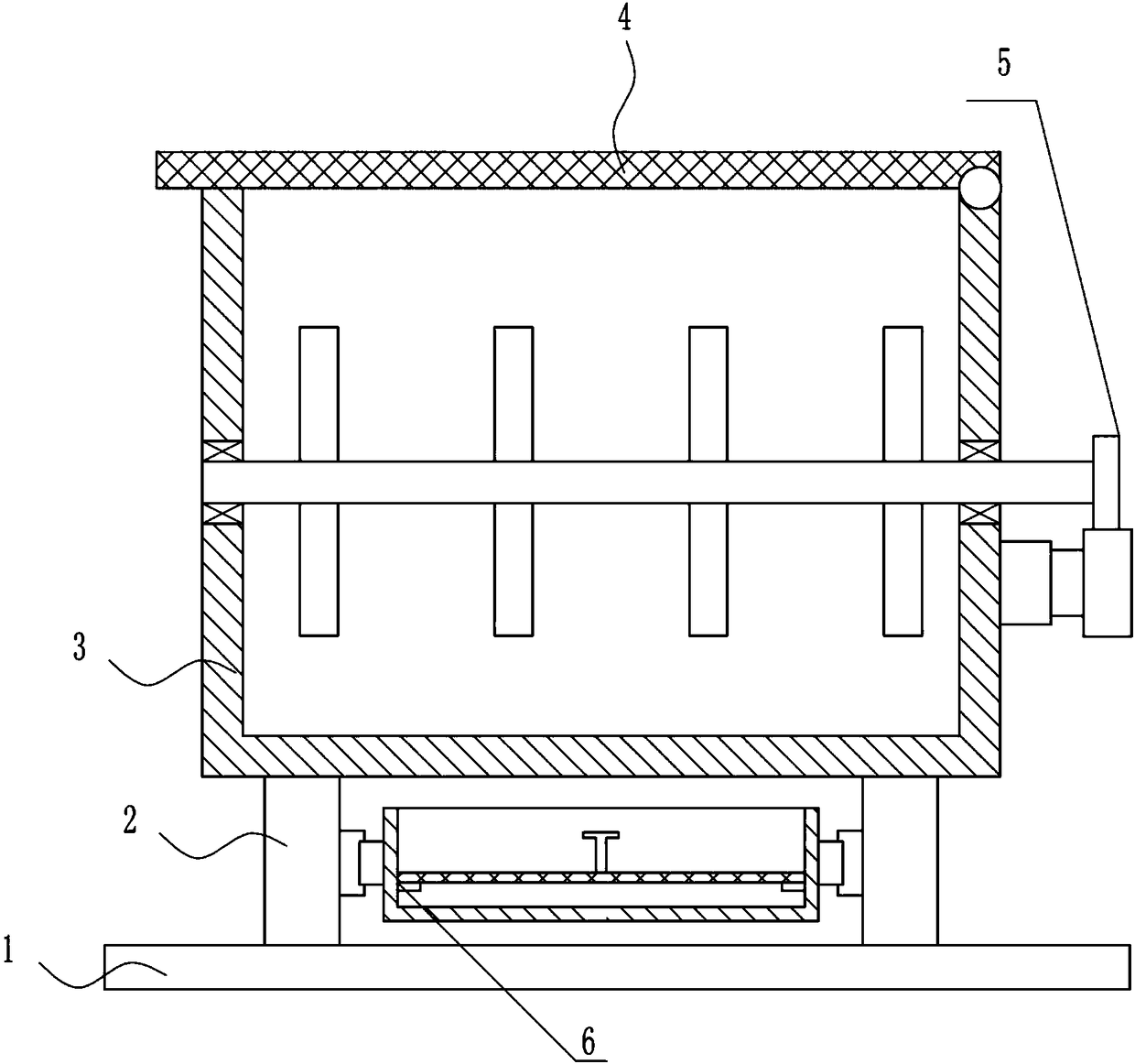

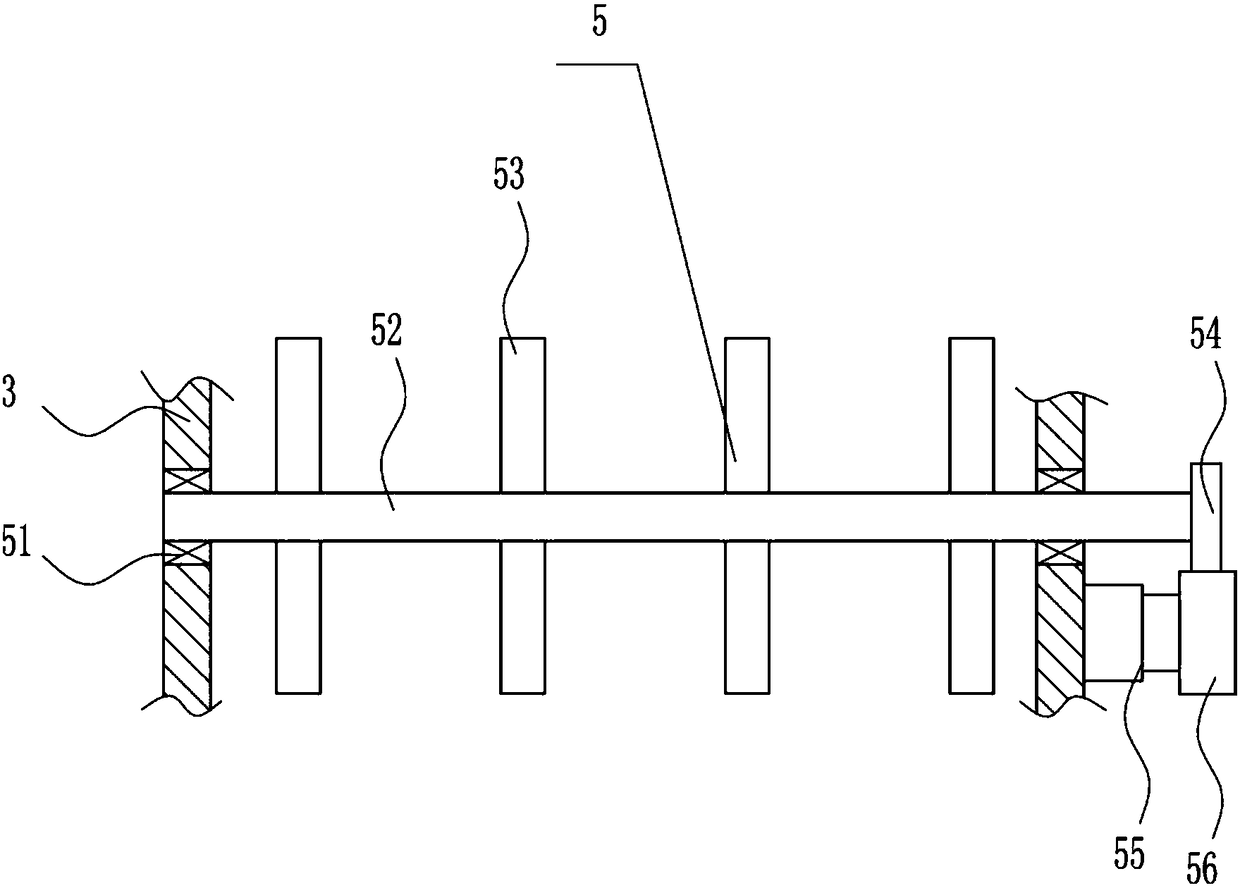

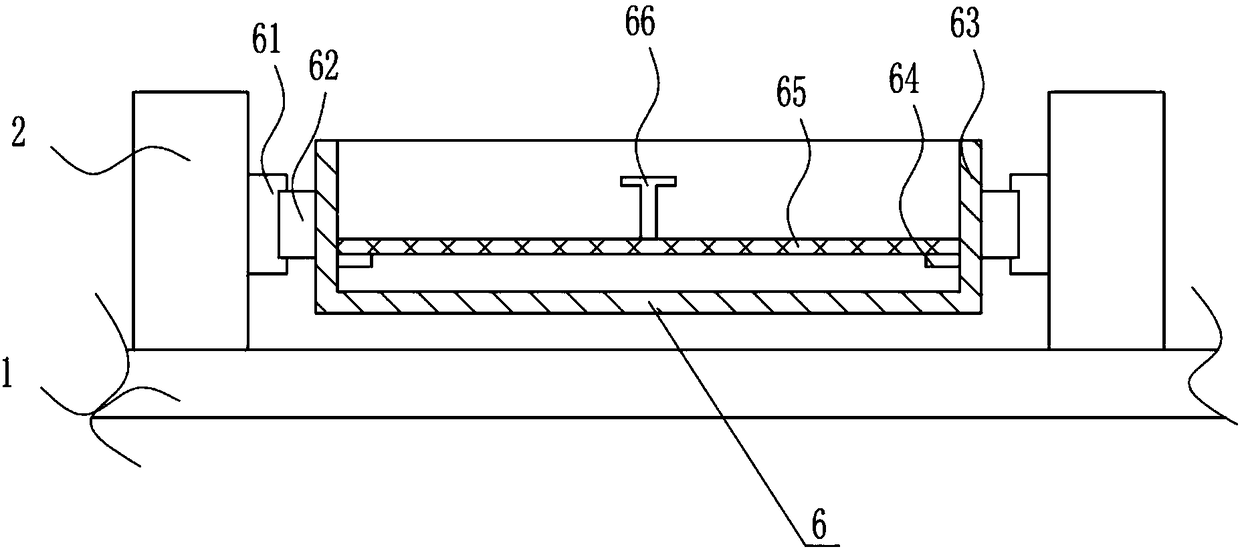

[0040] A collection device for monitoring construction site dust compliance, such as Figure 1-9 As shown, it includes a base plate 1, supporting legs 2, a first placement frame 3, a mesh plate 4, a stirring device 5 and a placing device 6, and the left and right sides of the top of the bottom plate 1 are symmetrically equipped with supporting legs 2, and the left and right sides of the supporting legs 2. A placement device 6 is arranged between the inner sides. A first placement frame 3 is installed between the tops of the legs 2 on the left and right sides. A stirring device 5 is arranged in the middle of the first placement frame 3. The stirring parts of the stirring device 5 are located in the first placement In the frame 3, the top of the first placing frame 3 is provided with a net plate 4, and the bottom right side of the net plate 4 is connected with the top right side of the first placing frame 3 by pins, and the net plate 4 cooperates with the first placing frame 3. ...

Embodiment 2

[0042] A collection device for monitoring construction site dust compliance, such as Figure 1-9 As shown, it includes a base plate 1, supporting legs 2, a first placement frame 3, a mesh plate 4, a stirring device 5 and a placing device 6, and the left and right sides of the top of the bottom plate 1 are symmetrically equipped with supporting legs 2, and the left and right sides of the supporting legs 2. A placement device 6 is arranged between the inner sides. A first placement frame 3 is installed between the tops of the legs 2 on the left and right sides. A stirring device 5 is arranged in the middle of the first placement frame 3. The stirring parts of the stirring device 5 are located in the first placement In the frame 3, the top of the first placing frame 3 is provided with a net plate 4, and the bottom right side of the net plate 4 is connected with the top right side of the first placing frame 3 by pins, and the net plate 4 cooperates with the first placing frame 3. ...

Embodiment 3

[0045] A collection device for monitoring construction site dust compliance, such as Figure 1-9 As shown, it includes a base plate 1, supporting legs 2, a first placement frame 3, a mesh plate 4, a stirring device 5 and a placing device 6, and the left and right sides of the top of the bottom plate 1 are symmetrically equipped with supporting legs 2, and the left and right sides of the supporting legs 2. A placement device 6 is arranged between the inner sides. A first placement frame 3 is installed between the tops of the legs 2 on the left and right sides. A stirring device 5 is arranged in the middle of the first placement frame 3. The stirring parts of the stirring device 5 are located in the first placement In the frame 3, the top of the first placing frame 3 is provided with a net plate 4, and the bottom right side of the net plate 4 is connected with the top right side of the first placing frame 3 by pins, and the net plate 4 cooperates with the first placing frame 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com