A drop-type buffer solution gradient operation system and its operation method

A buffer solution and operating system technology, which is applied in the direction of material analysis, instruments, and measuring devices by electromagnetic means, can solve the problems of decreased separation stability, time-consuming, and complicated operation, so as to improve the separation stability and shorten the analysis time. time, the effect of improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

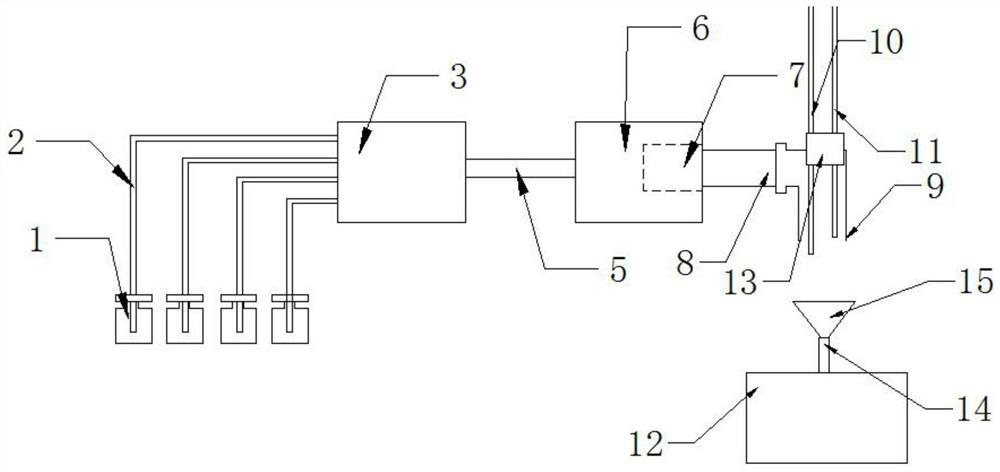

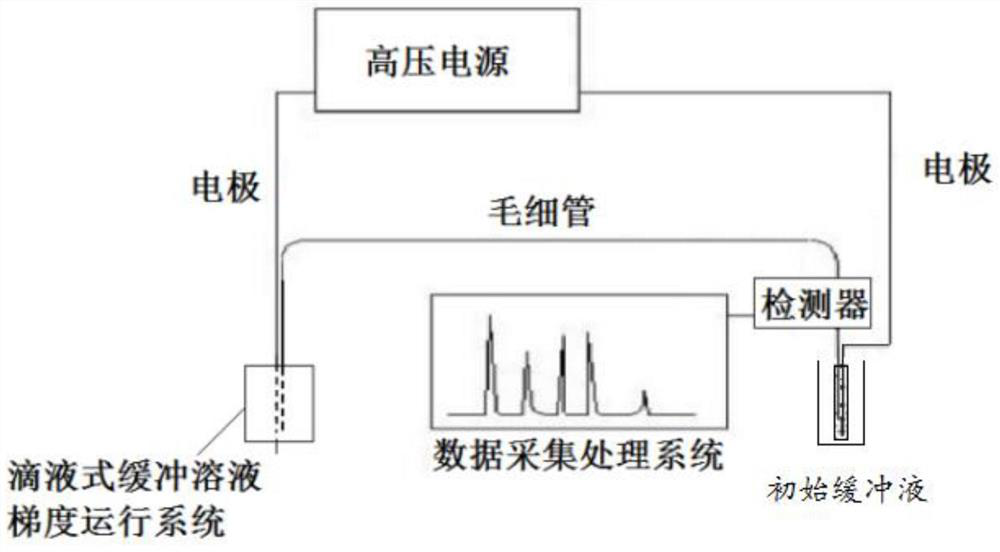

[0024] Such as Figure 1-2 A drop-type buffer solution gradient operation system is shown, including at least four liquid storage bottles 1 for storing buffer solutions, and various solutions required for preparing buffer solutions are stored in each liquid storage bottle 1, and the liquid storage bottles 1 is connected to the ratio control unit 3 that adjusts the ratio of the solution through the first conduit 2, and the solutions in each storage bottle 1 are mixed in the ratio control unit 3 according to a predetermined ratio, so that the ratio of the buffer solution can be changed at any time without the need for separate re-deployment. The proportional control unit 3 is connected with the flow control unit 6 through the second conduit 5, and the output end of the peristaltic pump 7 in the flow control unit 6 is connected with a drip head 9, and the peristaltic pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com