Single-piece permeameter, device for measuring single-piece test sample and measuring method

A technology of measuring device and magnetic permeability meter, which is applied in the direction of measuring device, magnetic property measurement, and magnetic variable measurement, can solve problems such as poor adaptability, error, and complicated operation, and achieve improved accuracy, improved adaptability, and simple and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

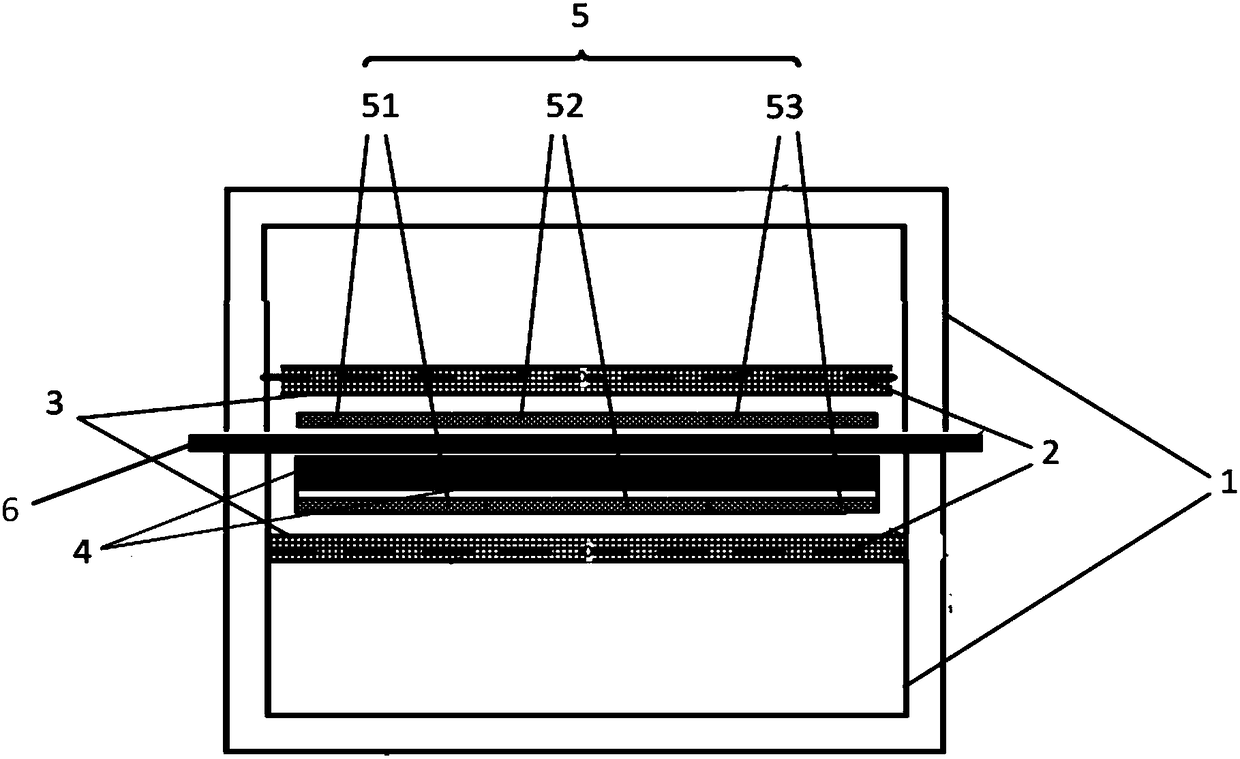

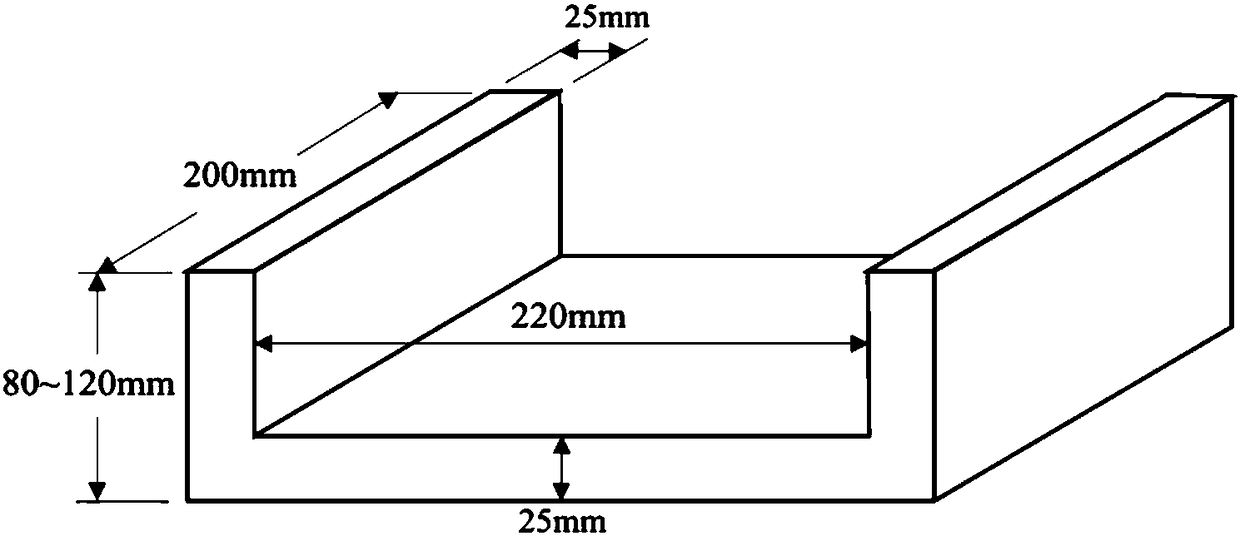

[0024] An embodiment of the present invention provides a single-chip permeability meter, such as figure 1 As shown, the single-chip permeability meter includes: a U-shaped double yoke 1 , a frame 2 , a primary winding 3 , a pair of H coils 4 , and a secondary winding 5 . Among them, the frame 2 is located between the U-shaped double yokes 1; the primary winding 3 is distributed on the frame 2. In actual testing, the sample 6 to be tested is placed in the frame 2, the H coil pair 4 includes two H coils, and the H coil pair 4 is located under the sample; the secondary winding 5 is located inside the primary winding 3, and the secondary winding 5 includes two Three winding sub-windings: left winding 51, middle winding 52, right winding 53, left winding 51, middle winding 52 and right winding 53 are provided with input port and output port respectively, through accessing different sub-windings The input port and the output port are selected to be connected to one or more of the l...

Embodiment 2

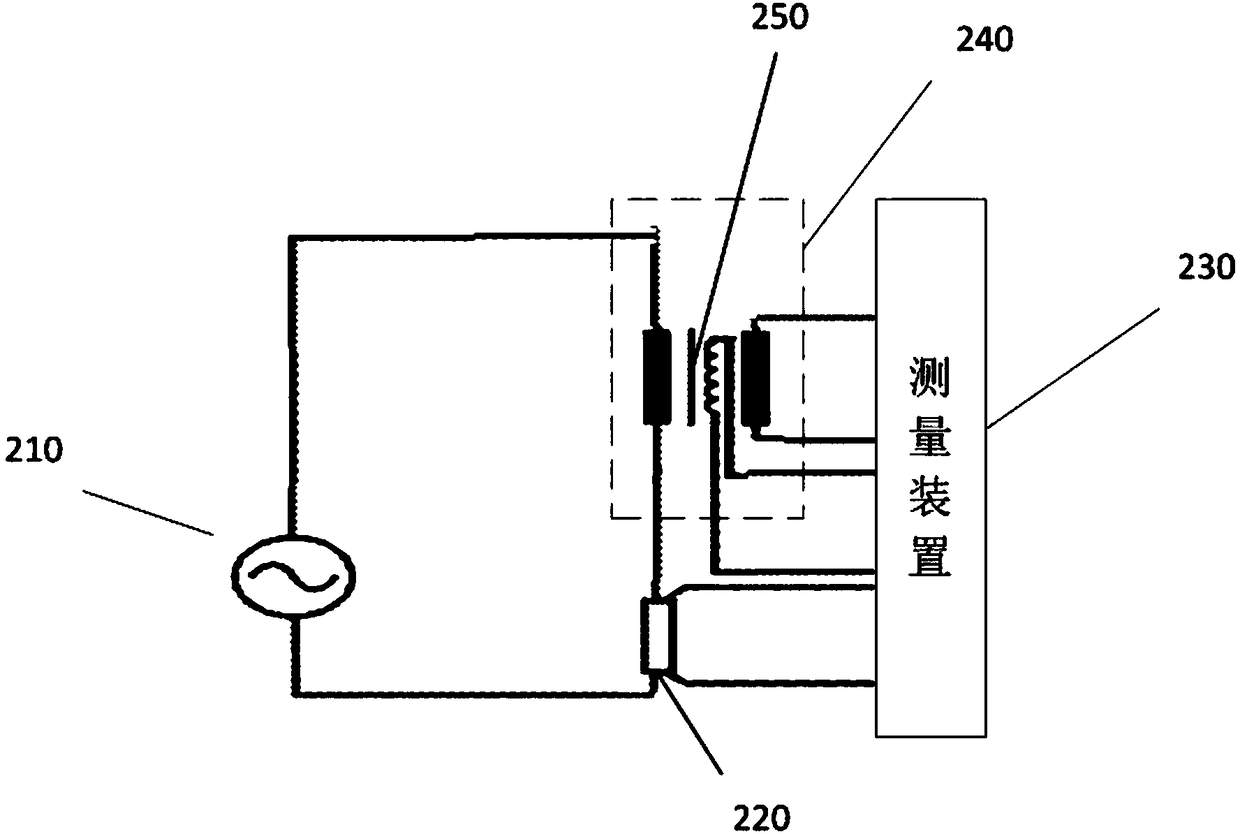

[0033] An embodiment of the present invention provides a single-chip sample measuring device, such as image 3 As shown, it includes: an AC magnetizing power supply 210, a non-inductive precision resistor 220, a measuring device 230, and a single-chip permeability meter 240, wherein the single-chip permeability meter 240 can be the single-chip permeability meter described in Embodiment 1 above. Please refer to the description in Embodiment 1 for details, and details will not be repeated here.

[0034] The AC magnetizing power supply 210 is used to supply power for the monolithic permeability meter 240; one end of the non-inductive precision resistor 220 is connected to the AC magnetizing power supply 210, and the other end of the non-inductive precision resistor 220 is connected to the monolithic permeability meter 240; the measuring device 230 is used to measure the induced voltage of the H coil pair 4 and the induced voltage of the secondary winding 5 in the single-chip permea...

Embodiment 3

[0052] An embodiment of the present invention provides a method for measuring a single piece of sample, such as Figure 4 As shown, the single-piece sample measurement method can be applied to the single-piece sample measurement device described in Embodiment 2, including:

[0053] Step S1: placing the sample 6 to be tested in the single-chip magnetic permeability meter 240;

[0054] Step S2: Connect the input ports and output ports of different sub-windings to select one or more of the left winding, the middle winding, and the right winding;

[0055] Step S3: Measure the induced voltage of the H coil pair 4 and the induced voltage of the secondary winding 5 in the monolithic permeability meter 240, and calculate the sample 6 to be tested according to the induced voltage of the H coil pair 4 and the induced voltage of the secondary winding 5 magnetic parameters.

[0056] Specifically, the above single-chip sample measurement method adopts the H-coil test method, and uses the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com