Terminal inserting machine

A technology of insertion machine and terminal, which is applied in the assembly/disassembly of contacts, etc., can solve the problems of difficult automatic insertion, high error rate of manual insertion, and waste, so as to save manpower and material resources, avoid error-prone, and scrap rate Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further describe the technical features and effects of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

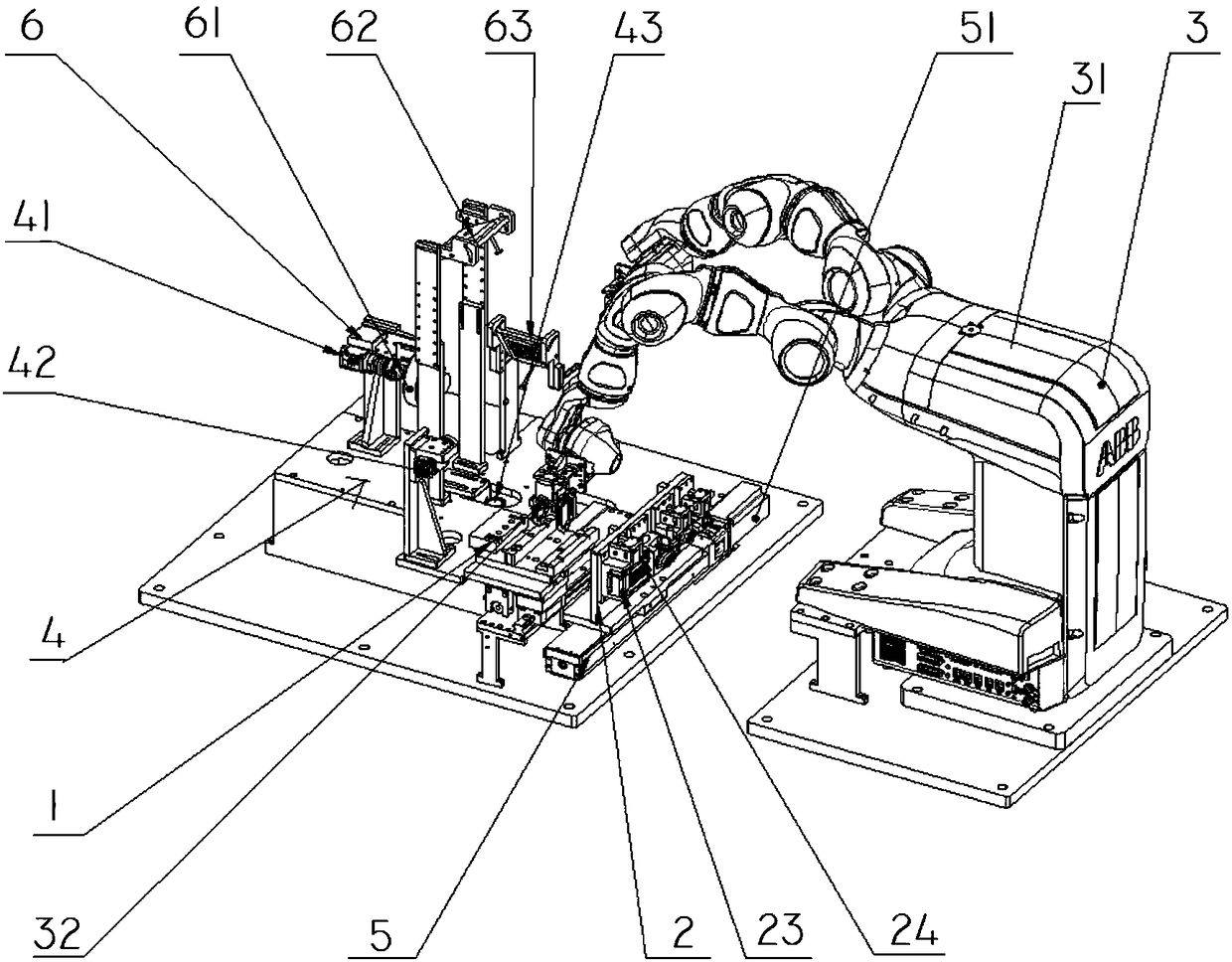

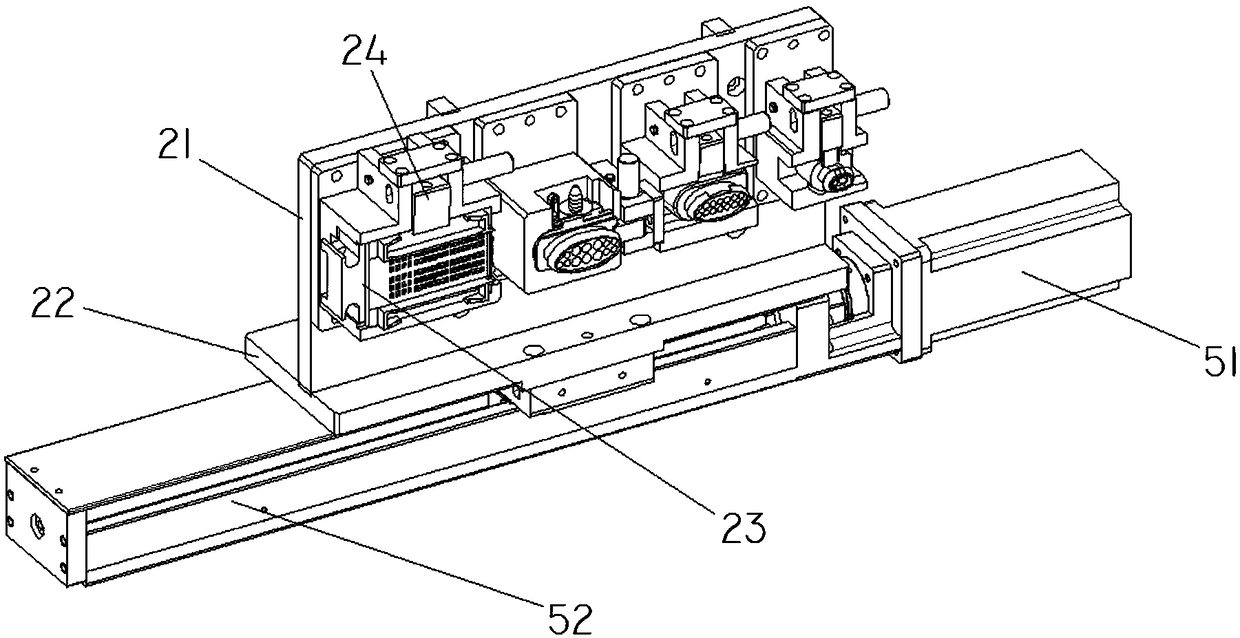

[0018] refer to Figure 1-Figure 4 , a terminal insertion machine, including a clamping device 3, a wire fixing device 1, a sheath fixing device 2, a camera system 4, a linear motion module 5, and a lighting system 6; the wire fixing device 1 is arranged on a tooling plate 7 Above, the sheath fixing device 2 is set on the linear motion module 5, the linear motion module 5 is set next to the wire fixing device 1, the camera system 4 and the lighting system 6 are both set on the tooling plate 7, located on the wire fixing device 1 Next to it, the clamping device 3 is arranged beside the tooling plate 7 .

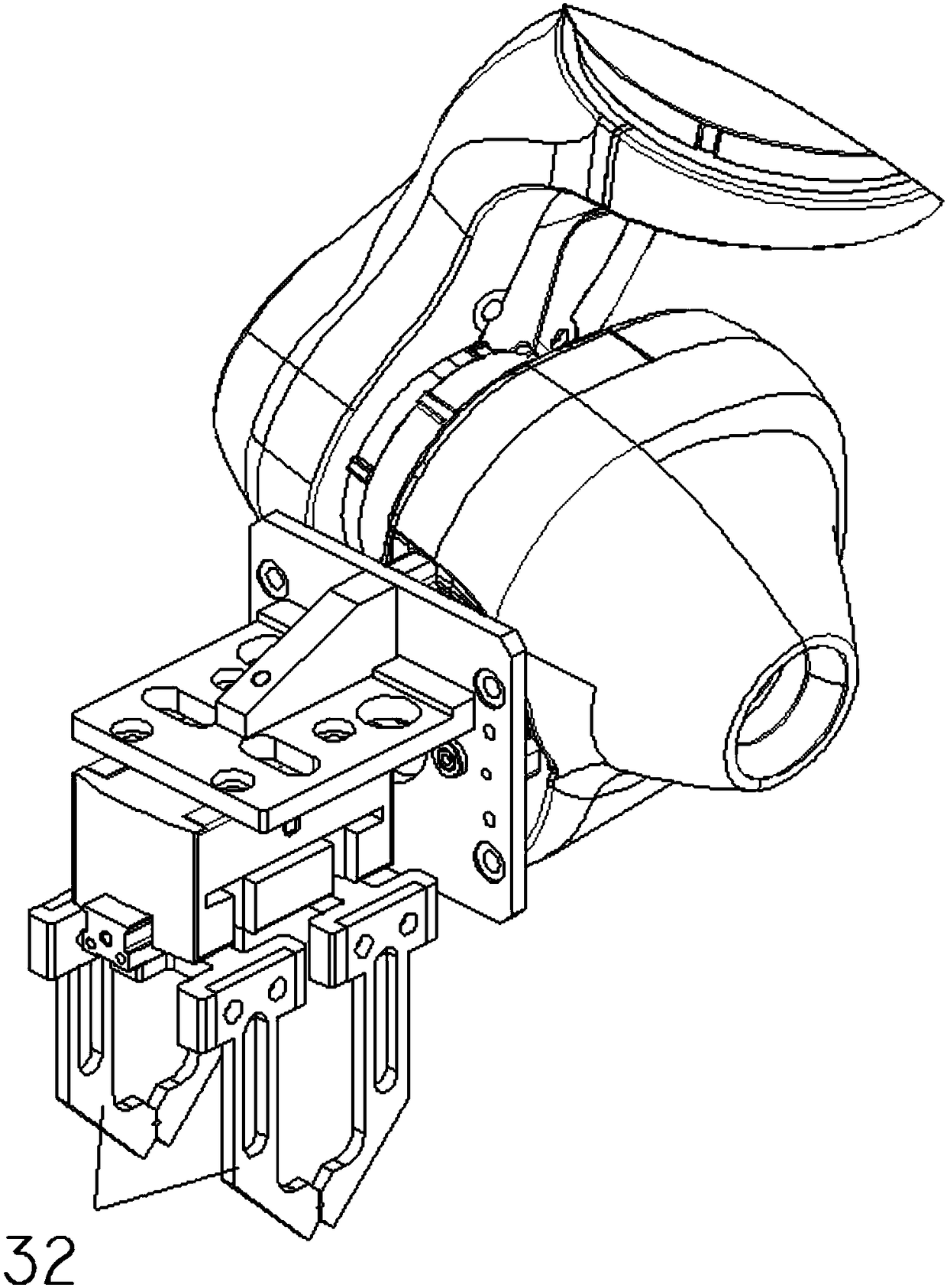

[0019] Further, the clamping device 3 includes a mechanical arm 31 , and two clamping jaws 32 are arranged at the end of the mechanical arm 31 .

[0020...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com