Guide slot equipment for plastic steel profiles

A technology of guide grooves and profiles, which is applied in the field of guide groove equipment for plastic steel profiles, and can solve the problem that the size and depth of grooves cannot be changed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

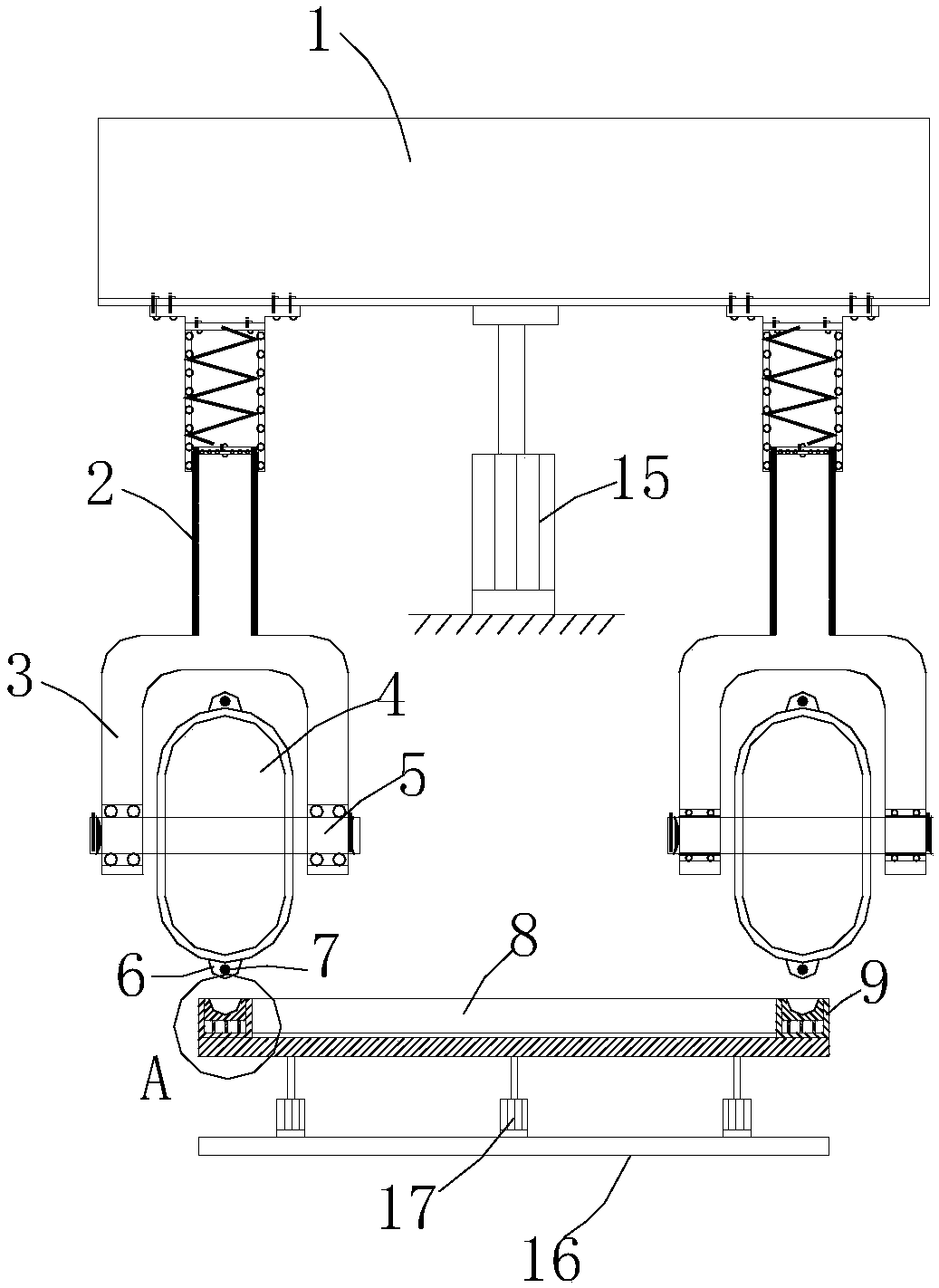

[0014] Such as Figure 1 to Figure 3 As shown, a guide groove device for plastic steel profiles includes a movable connecting plate 1, a support rod 2 is provided at the bottom of the connecting plate 1, and a "U"-shaped splint 3 is provided at the end of the support rod 2, and a "U"-shaped splint 3 is provided. The splint 3 is provided with a rotating pressure wheel 4, which is connected to the "U"-shaped splint 3 through a movable pin shaft 5, and an annular flange 6 is arranged on the peripheral surface of the rotating pressure wheel 4, and an electric heater is embedded in the annular flange 6. Wire 7 is provided with a guide groove mold under the rotating pinch wheel 4;

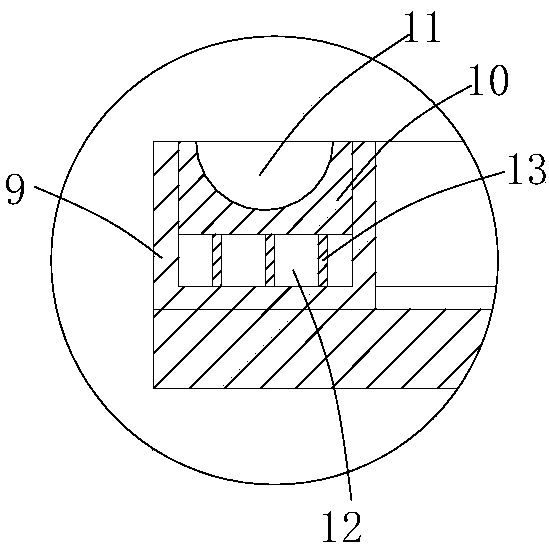

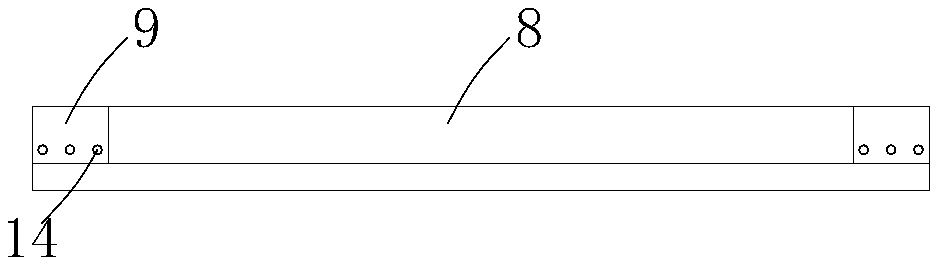

[0015] The guide groove mold comprises a guide groove platform 8, a guide groove plate 9 is provided on both sides of the guide groove platform 8, a placement groove is provided in the guide groove plate 9, a guide groove base 10 is provided in the placement groove, and a guide groove base 10 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com