A kind of construction method of deep foundation pit

A construction method and technology for deep foundation pits, which are applied in basic structure engineering, excavation, construction, etc., can solve problems such as easy deformation, decrease in strength of steel sheet piles, and increase in reverse transportation costs, so as to avoid mutual influence, fast construction, and construction. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In the embodiment of the present invention, the depth of the deep foundation pit of the main pier reaches 10.5m, and the length is 42m. If the most commonly used 12m-long Larsen IV-type steel sheet pile is used as the enclosure wall, the traditional method cannot realize the soil retaining Due to the effect of water, the method of excavating at intervals and pouring the back cover of the present invention effectively solves the problem of insufficient length of the steel sheet piles, greatly improves the construction speed and reduces the cost.

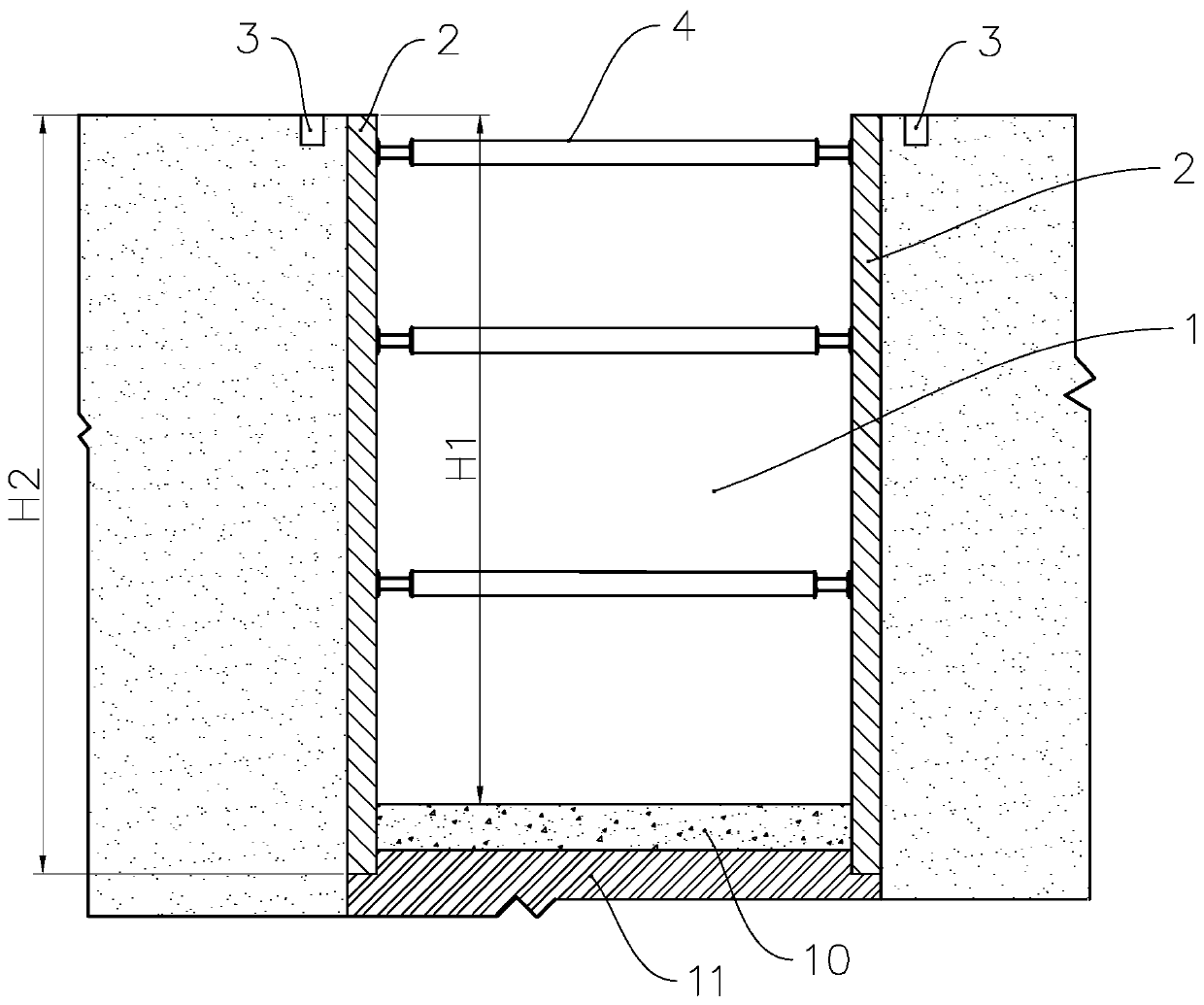

[0020] see figure 1 , figure 1 It is a structural schematic diagram of a deep foundation pit embodiment of the present invention. In this embodiment, the depth H1 of the deep foundation pit 1 is 10.5m, the length H2 of the steel sheet pile 2 is 12m, and the bottom of the deep foundation pit 1 is provided with a concrete sealing layer 10, and the main pier is constructed on the surface of the concrete sealing layer 10. Before ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com