An anti-windback structure for the top cylinder of the smoke collecting hood of a gas water heater

A technology for gas water heaters and smoke collection hoods, which is applied to fluid heaters, combustion methods, exhaust gas devices, etc. It can solve problems such as affecting appearance, bursting pipe fittings, scratches by staff, etc., and achieves the effect of avoiding scratch accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

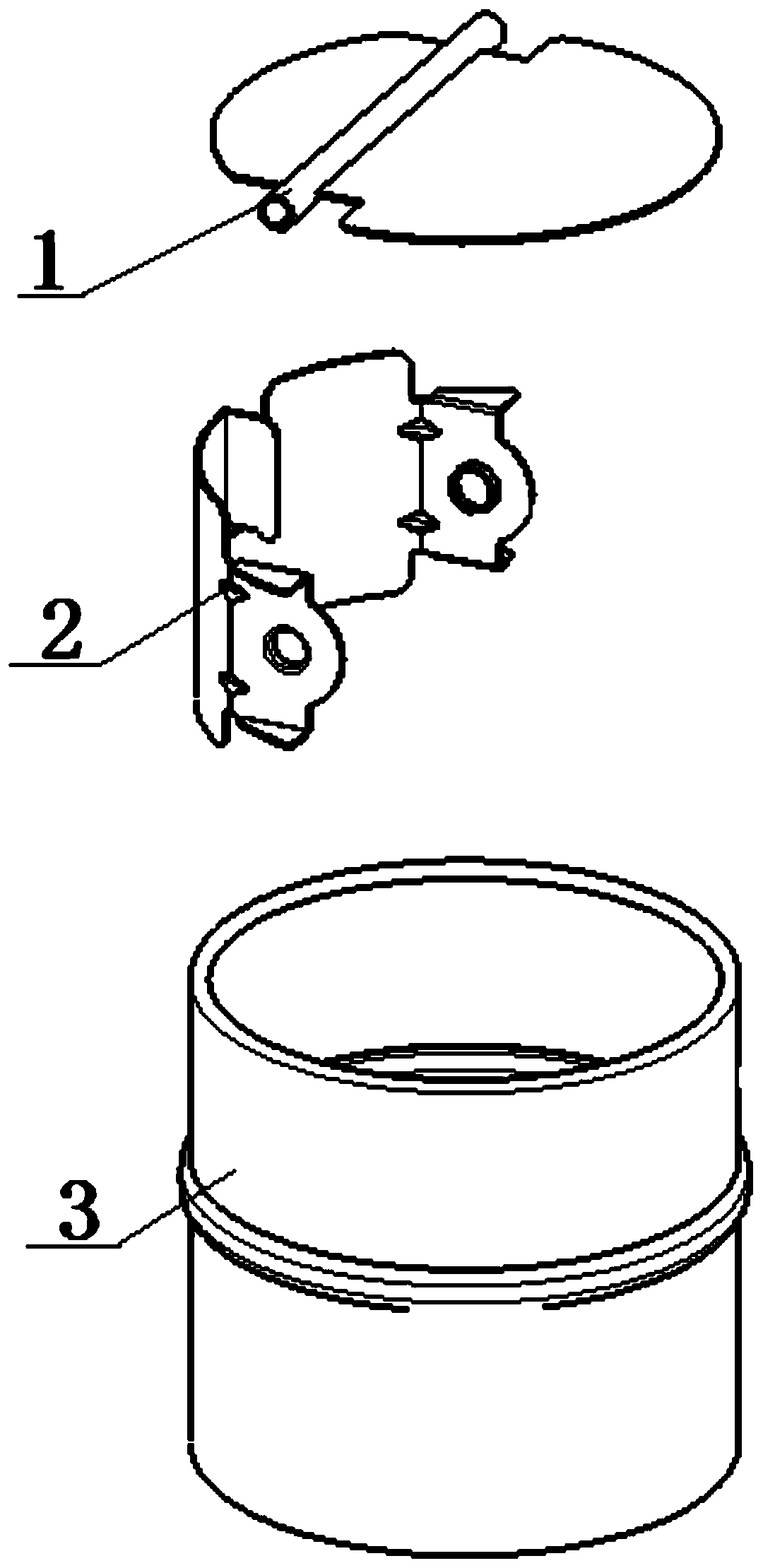

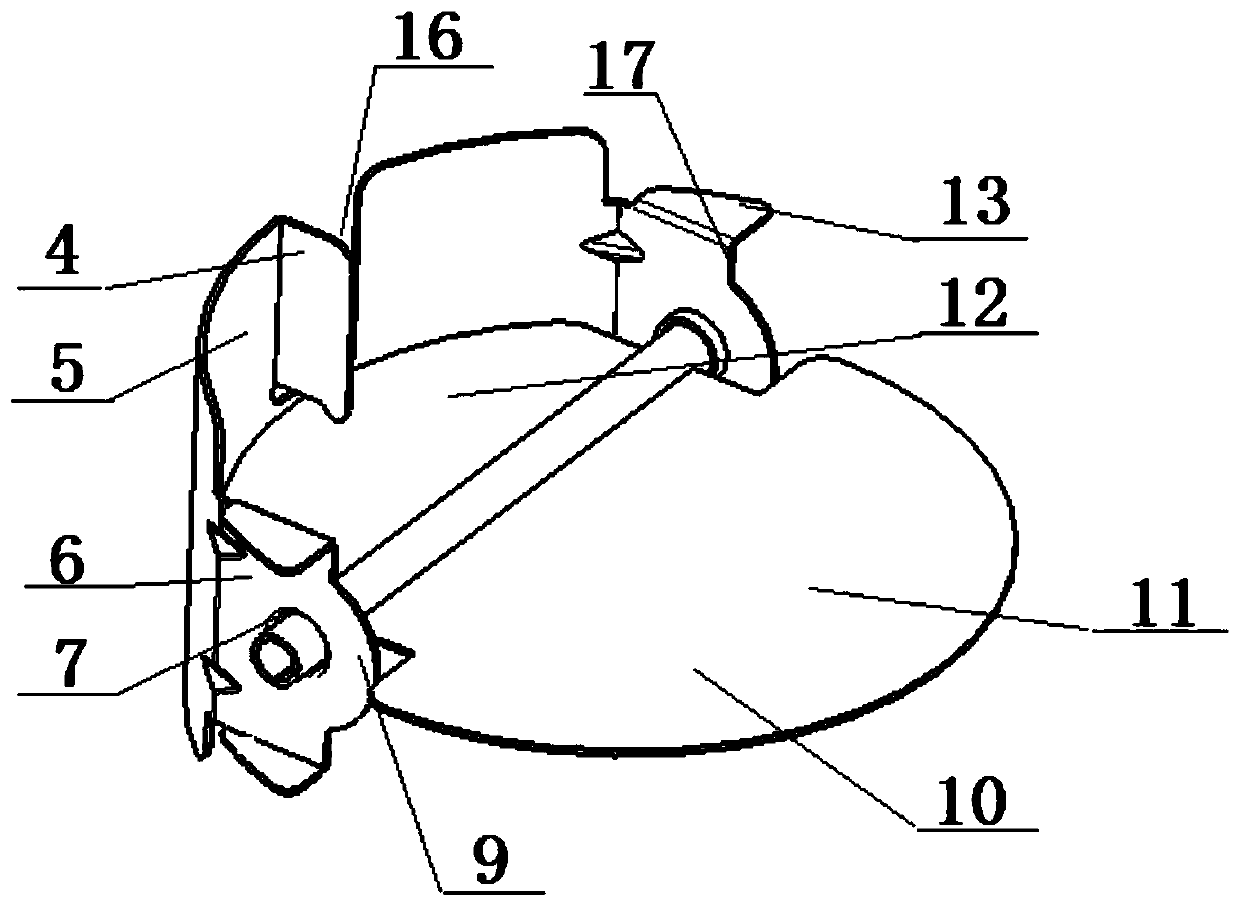

[0040] Such as figure 2 As shown, the support frame 2 includes two fixing pieces 6 arranged vertically near the inner wall of the top cylinder 3, and the two fixing pieces 6 are arranged symmetrically with respect to the vertical diameter section of the top cylinder 3; the fixing piece 6 is provided with a supply pin shaft 1 socket 7 for plugging. Let the end of the pin shaft 1 pass through the socket 7 and place it in the gap between the fixing member 6 and the inner wall of the top cylinder 3 after the support frame 2 is inserted into the interior of the top cylinder 3 .

[0041] The socket 7 is a through hole with a circular cross section, and the pin shaft 1 is correspondingly columnar, and the pin shaft 1 is inserted into the socket 7 and is flexibly connected.

[0042] preferred, such as Figure 4 , 5 As shown, the socket 7 is provided with a flanging 8 formed by bending toward the inside of the top cylinder 3. The flanging 8 is a tapered surface that gradually shrin...

Embodiment 2

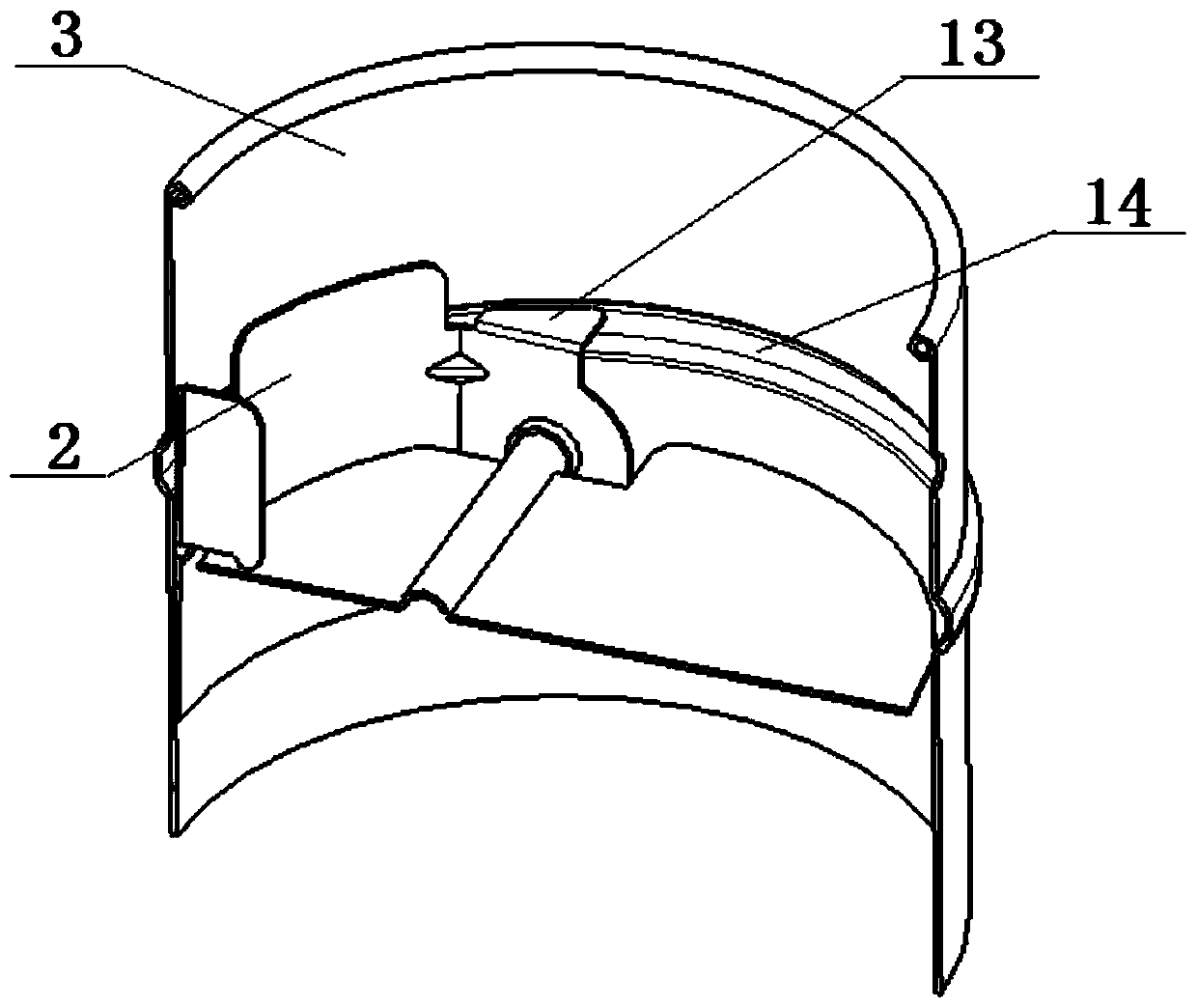

[0046] Such as figure 2 , 3 As shown, the upper end and / or lower end of the fixing member 6 is bent outward to form a positioning plate 13, and the inner wall of the top cylinder is provided with a corresponding groove 14. After the support frame 2 is inserted into the inside of the top cylinder 3, the positioning plate 13 Insert it into the groove 14 to limit insertion.

[0047] The above setting realizes the positioning connection between the support frame 2 and the top cylinder 3, and the staff can realize the complete fixed connection between the support frame 2 and the top cylinder 3 by spot welding the position. The gap between the inner walls of the tube 3 ensures the airtightness when closing the inner channel of the top tube 3 .

[0048] The groove 14 is an annular groove.

[0049] The above setting is convenient for adjusting the solder joints between the support frame 2 and the top tube 3 according to the requirement.

Embodiment 3

[0051] Such as figure 1 As shown, the first side of the fixing member 6 is provided with a radially protruding semicircular rotating part 9 corresponding to the socket 7, and the rotating baffle plate 11 rotates and moves along the outer circumference of the semicircular rotating part 9 , and sealed contact.

[0052] The above setting does not affect the rotation of the baffle plate 11 matching the inner passage of the top cylinder 3, and ensures the airtightness when closing the inner passage of the top cylinder 3.

[0053] The second sides of the two fixing parts 6 are connected through the support frame main body 5 , and the support frame main body 5 is fixedly connected with the inner wall of the top cylinder 3 .

[0054] The fixing part 6 may deform to the inside of the top tube 3 after long-term use. Once the fixing part 6 is deformed, it will affect the sensitivity of the pin shaft 1 rotation, thereby affecting the rotation of the baffle plate 11. The above-mentioned set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com