Detection apparatus and detection method of surface cleaning effect of cold-rolled sheet

A surface cleaning and detection device technology, applied in the field of steel rolling process, can solve the problems of interference, uneven distribution of force, inability to distinguish the degree of alkali cleaning, etc., to improve safety, improve accuracy, reliable means and data support Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

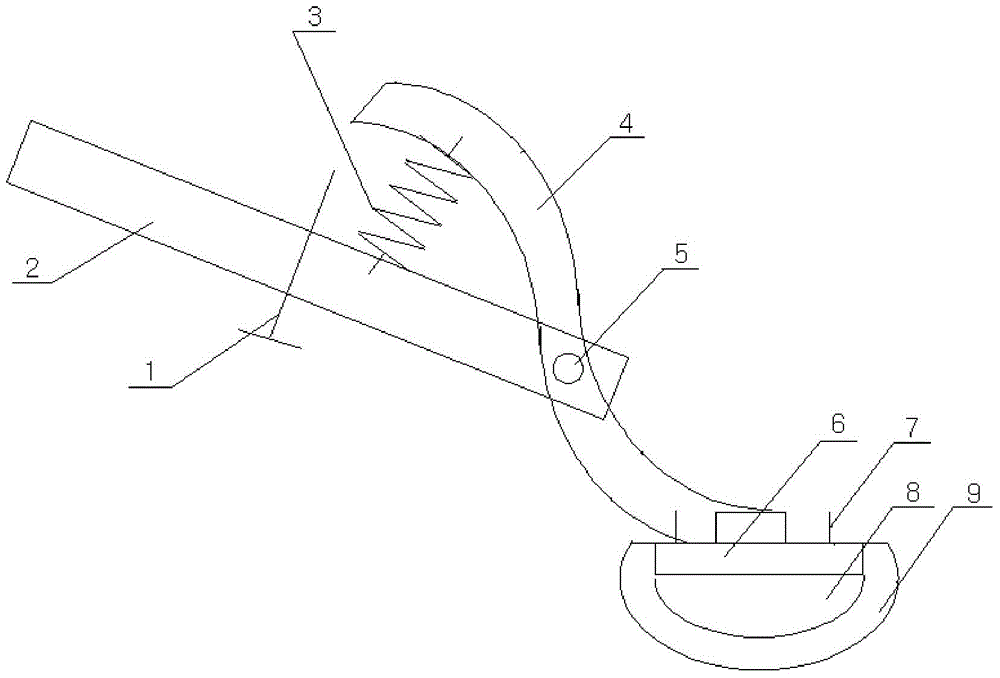

[0022] Depend on figure 1 It can be seen that the surface cleaning effect detection device of the cold-rolled sheet of the present invention is composed of a limit bolt 1, a handle 2, a spring 3, a working arm 4, a pin shaft 5, and a contact pad 6. The handle 2 is a straight rod, and the front end of the straight rod is processed with a pin hole; the working arm 4 is in an "S" shape, and the middle part is also provided with a pin hole; the contact pad 6 is rectangular (or round or oval), The upper surface of the pad 6 is provided with a screw hole, and the screw hole is internally threaded with a screw 7 for fixing the sponge 8 and the test pad 9. The test pad 9 is wrapped on the outside of the sponge 8. The test pad 9 can be made of paper or can be made of paper. Cotton, wool, linen, chemical fiber fabrics. The middle part of the working arm 4 is movably connected to the front end of the handle 2 through a pin shaft 5 and can rotate around the pin shaft 5 . The middle part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com