a pt/mos 2 Nanocatalyst and its preparation method and application

A nano-catalyst and nano-sheet technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of high price and achieve the effect of less special equipment, high catalytic activity, and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

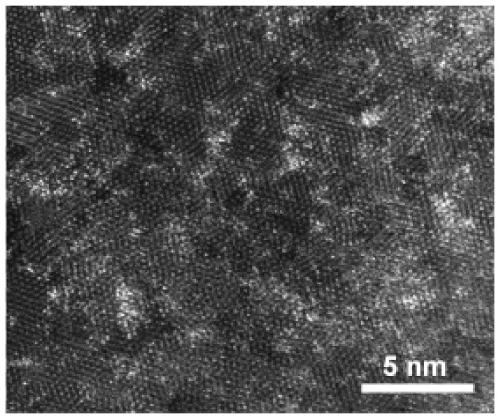

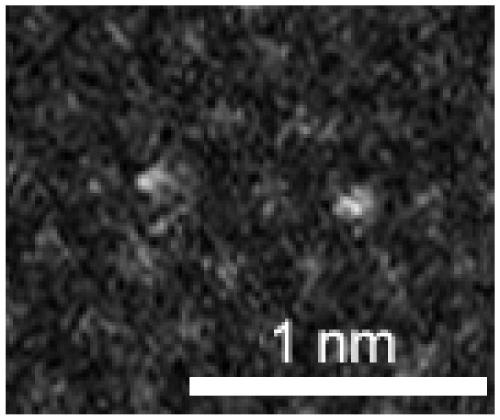

[0041] Pt / MoS 2 Preparation of nanocatalysts

[0042] (1) Mix (NH 4 ) 6 Mo 7 o 24 4H 2 O and thiourea were dissolved in deionized water, (NH 4 ) 6 Mo 7 o 24 4H 2 The quality of O is 1.22g, the quality of thiourea is 1.07g, the volume of deionized water is 34mL, after stirring for 40min, carry out hydrothermal reaction, the temperature of hydrothermal reaction is 218 ℃, the time of hydrothermal reaction is 17.5h, then Cool to room temperature, and centrifuge the solid material cooled to room temperature. The speed of centrifugation is 7600 rpm, and the time of centrifugation is 5 minutes. The product obtained by centrifugation is ultrasonically washed with a polar solvent for 2 minutes, and then centrifuged. , the speed of centrifugation is 7600 rpm, the time of centrifugation is 7min, and the product obtained by centrifugation is ultrasonically washed with polar solvent for 1min, and dried in vacuum at 61°C overnight to obtain MoS 2 Nanosheets;

[0043] (2) MoS 2 ...

Embodiment 2

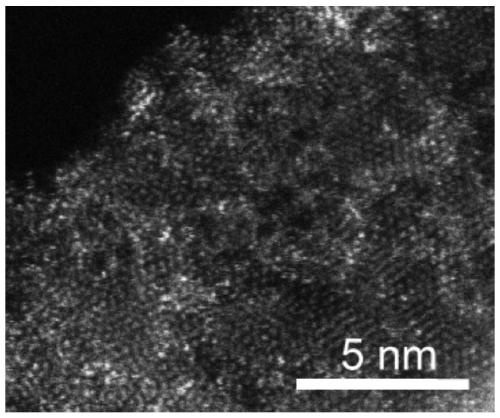

[0046] Pt / MoS 2 Preparation of nanocatalysts

[0047] (1) Mix (NH 4 ) 6 Mo 7 o 24 4H 2 O and thiourea were dissolved in deionized water, (NH 4 ) 6 Mo 7 o 24 4H 2 The mass of O is 1.21g, the mass of thiourea is 1.05g, the volume of deionized water is 34mL, after stirring for 40min, carry out hydrothermal reaction, the temperature of hydrothermal reaction is 215℃, the time of hydrothermal reaction is 17h, then cool to room temperature, the solid material cooled to room temperature is centrifuged, the centrifugation speed is 7000 rpm, the centrifugation time is 5min, the centrifuged product is ultrasonically washed with a polar solvent for 2min, and then the centrifugation is continued. The speed of centrifugation is 7000 rpm, the time of centrifugation is 5min, and the product obtained by centrifugation is ultrasonically washed with a polar solvent for 1min, and vacuum dried overnight at 58°C to obtain MoS 2 Nanosheets;

[0048] (2) MoS 2 The nanosheets were uniform...

Embodiment 3

[0051] Pt / MoS 2 Preparation of nanocatalysts

[0052] (1) Mix (NH 4 ) 6 Mo 7 o 24 4H 2 O and thiourea were dissolved in deionized water, (NH 4 ) 6 Mo 7 o 24 4H 2 The mass of O is 1.25g, the mass of thiourea is 1.08g, and the volume of deionized water is 36mL. After stirring for 50min, carry out hydrothermal reaction. The temperature of hydrothermal reaction is 225℃, and the time of hydrothermal reaction is 19h, then cool to room temperature, the solid material cooled to room temperature is centrifuged, the centrifugation speed is 8000 rpm, the centrifugation time is 7min, the centrifuged product is ultrasonically washed with a polar solvent for 2min, and then the centrifugation is continued. The speed of centrifugation is 8000 rpm, the time of centrifugation is 5min, and the product obtained by centrifugation is ultrasonically washed with a polar solvent for 2min, and vacuum-dried overnight at 62°C to obtain MoS 2 Nanosheets;

[0053] (2) MoS 2 The nanosheets were...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com