A kind of indium oxide nano-catalyst grown on rgo, its preparation method and its application

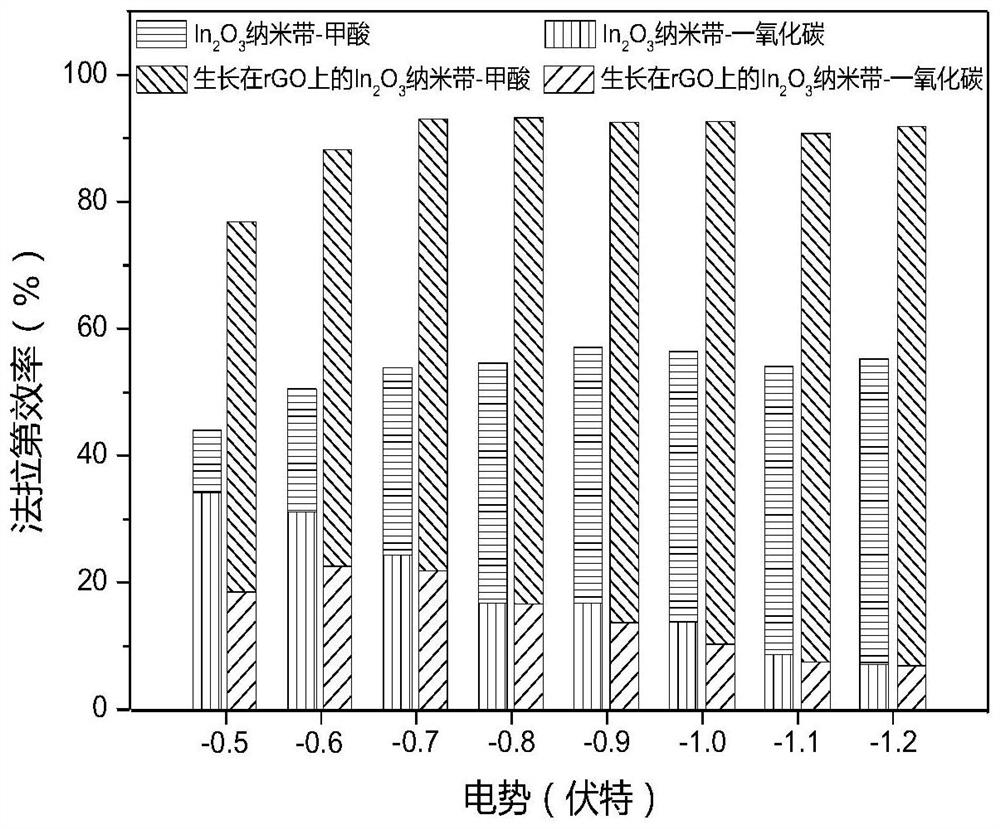

A nano-catalyst and nano-ribbon technology, applied in the field of In2O3 nano-catalysts, can solve the problems of poor catalytic activity, large size, and low atom utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

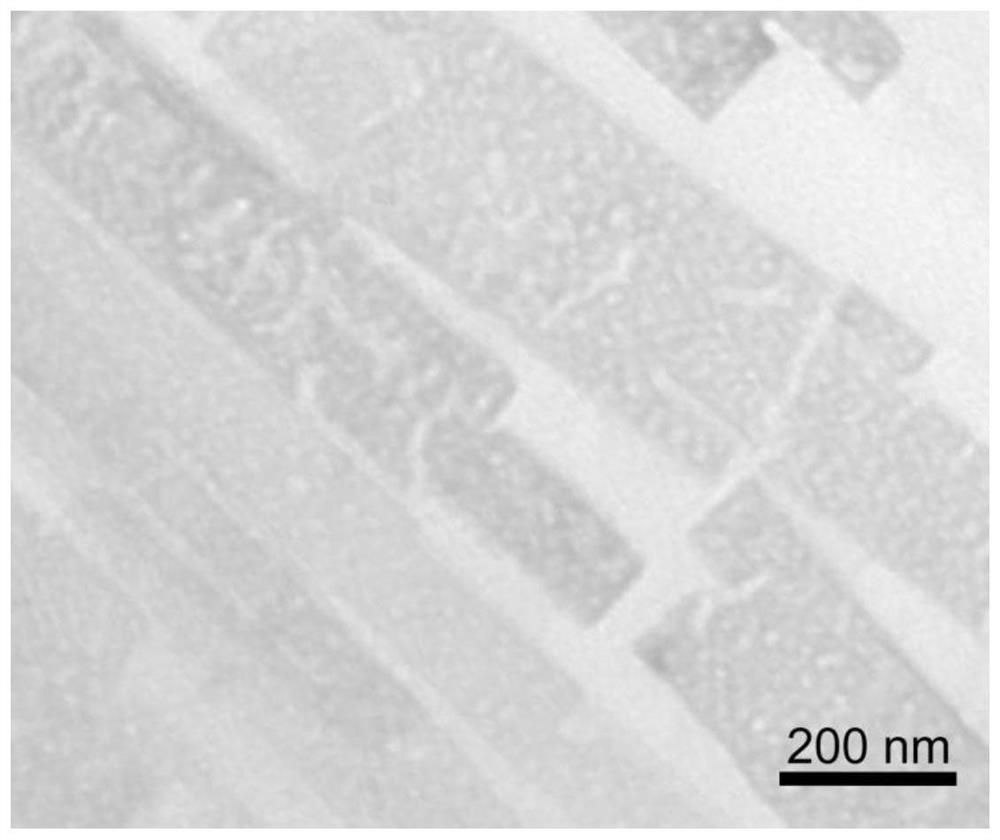

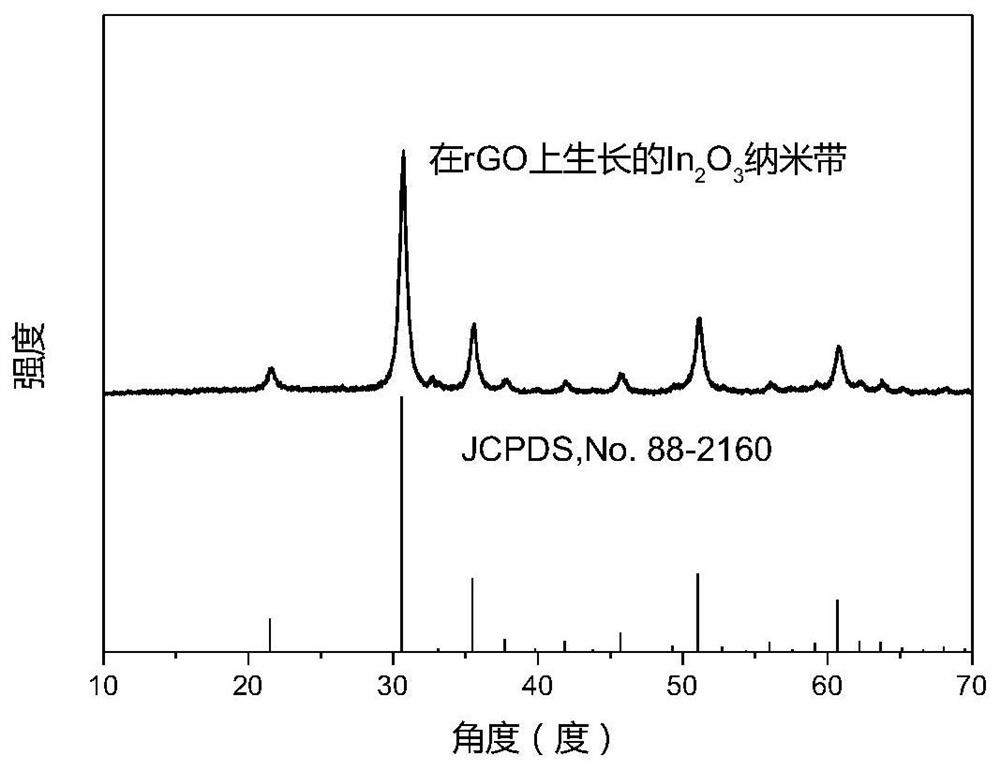

Image

Examples

preparation example Construction

[0033] The present invention provides an In grown on rGO described in the above technical scheme 2 o 3 The preparation method of nanometer catalyst comprises the following steps:

[0034] Disperse sodium oleate, indium trichloride tetrahydrate and reduced graphene oxide nanosheets in deionized water, and stir evenly to obtain a mixed solution;

[0035] The mixed solution is hydrothermally reacted, and the obtained reaction product is washed and dried to obtain In(OH) grown on rGO. 3 nanobelt;

[0036] In(OH) to be grown on rGO 3 Nanoribbons sintered to obtain In grown on rGO 2 o 3 nanocatalyst.

[0037] The method provided by the invention can obtain high loading and In2 o 3 Composite catalysts for uniform growth of nanoribbons. The method requires less special equipment and the product is easy to separate.

[0038] In the present invention, sodium oleate, indium trichloride tetrahydrate and reduced graphene oxide nanosheets are dispersed in deionized water and stirre...

Embodiment 1

[0058] In grown on rGO 2 o 3 Preparation of nanocatalysts

[0059] (1) Dissolve the reduced graphene oxide, sodium oleate and indium trichloride tetrahydrate into deionized water successively under stirring at room temperature. The mass of indium chloride was 95mg, the volume of deionized water was 40mL, and the hydrothermal reaction was carried out after stirring for 25min. Centrifuge the solid material cooled to room temperature, the speed of centrifugation is 7200 rpm, and the time of centrifugation is 5 minutes; the product obtained by centrifugation is ultrasonically washed with a polar solvent for 2 minutes, and then centrifugation is continued. The rotation speed is 7200 rpm, and the centrifugation time is 5 minutes; then the centrifuged product is ultrasonically washed with a polar solvent for 2 minutes. Finally, vacuum freeze-dry at -22 °C overnight to obtain In(OH) grown on rGO 3 nanobelt;

[0060] (2) In(OH) to be grown on rGO 3 The nanobelts were sintered in ...

Embodiment 2

[0071] In grown on rGO 2 o 3 Preparation of nanocatalysts

[0072] (1) Dissolve reduced graphene oxide, sodium oleate and indium trichloride tetrahydrate in deionized water under stirring at room temperature, the quality of reduced graphene oxide is 80 mg, the quality of sodium oleate is 270 mg, and the quality of trichloride tetrahydrate is 270 mg. The mass of indium chloride was 85mg, the volume of deionized water was 40mL, and the hydrothermal reaction was carried out after stirring for 30min. Centrifuge the solid material cooled to room temperature, the speed of centrifugation is 7600 rpm, and the time of centrifugation is 5 minutes; the product obtained by centrifugation is ultrasonically washed with a polar solvent for 2 minutes, and then centrifuged. The rotational speed was 7600 rpm, and the centrifugation time was 7 minutes; the centrifuged product was ultrasonically washed with a polar solvent for 1 minute. Finally, the In(OH) grown on rGO was obtained by vacuum f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com