A kind of Agco nano crystal and its catalyst, preparation method and application

A nanocrystal and catalyst technology, applied in the field of energy catalysts, can solve the problems of limited selectivity and conversion rate, and achieve the effects of high atom utilization, high reactivity, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

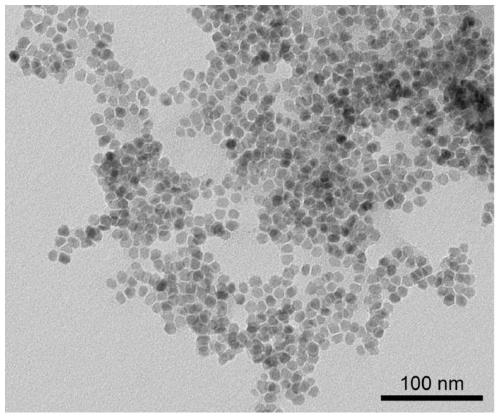

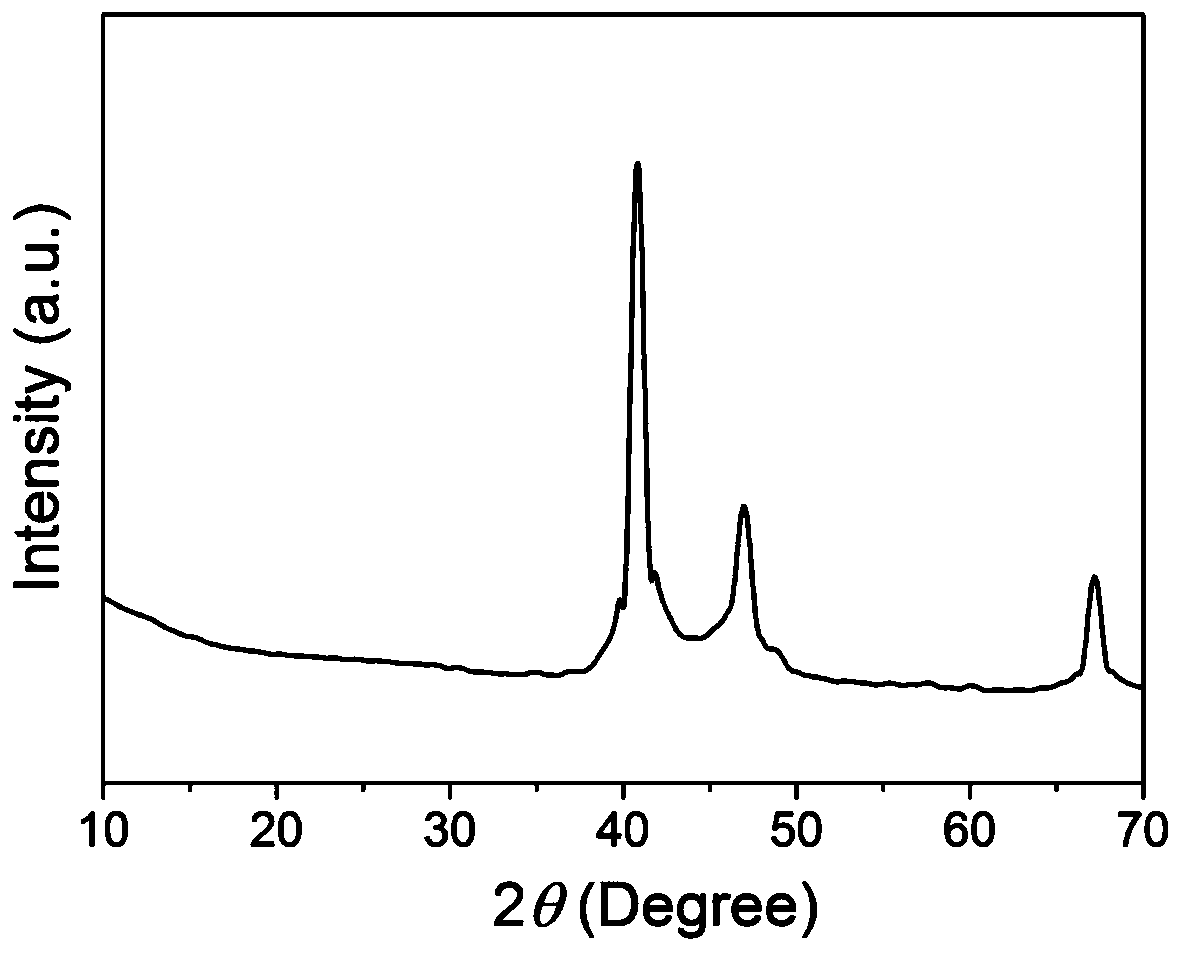

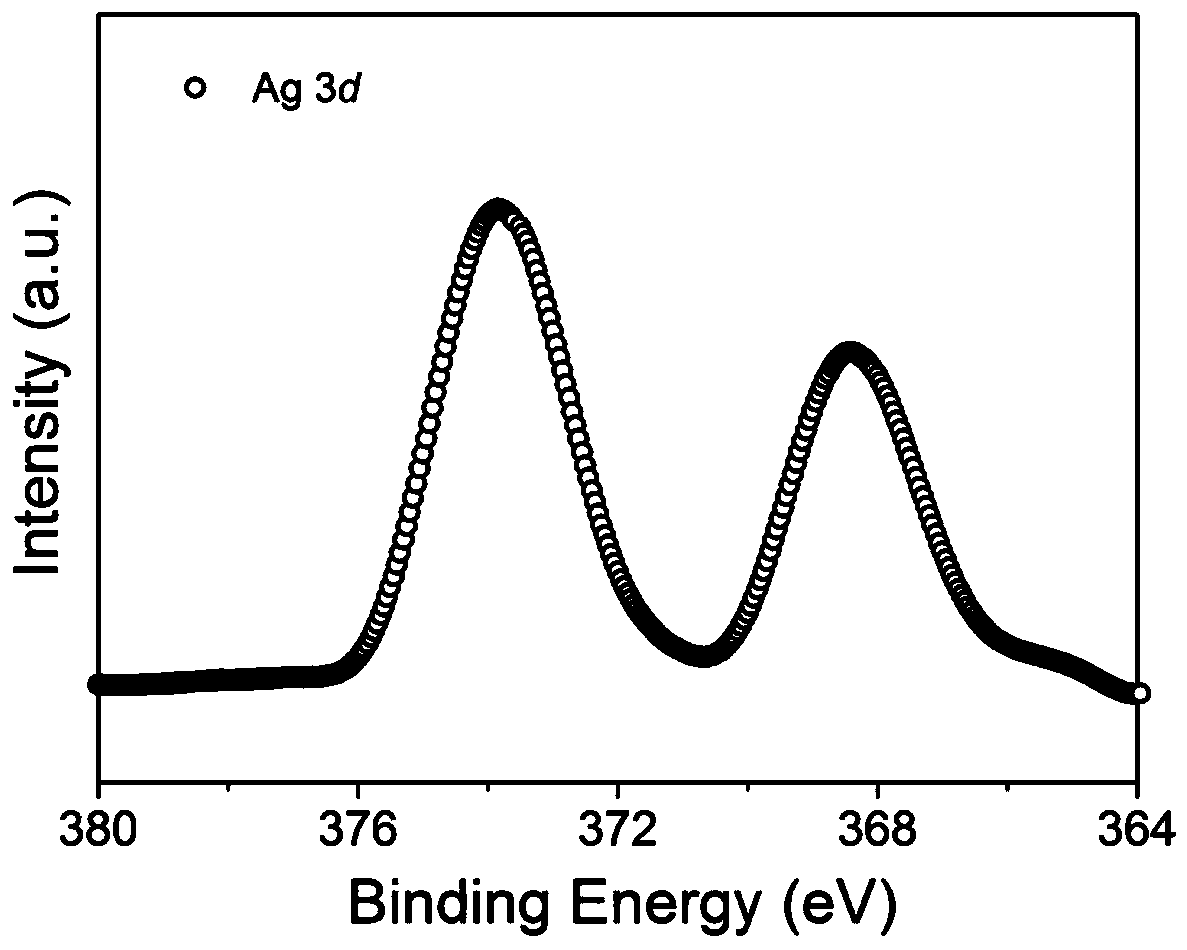

[0037] A method for preparing AgCo nanocrystals, comprising the steps of: mixing 23 parts of phenylene ether, 18 parts of oleylamine, 2.5 parts of oleic acid, cobalt acetylacetonate and silver acetate in parts by volume to obtain mixed solution A, cobalt acetylacetonate and benzene The mass volume ratio (g / L) of ether is 13:1, and the mass volume ratio (g / L) of silver acetate and phenyl ether is 7:1; preheat and stir the mixed solution A in an oil bath, and then add tert-butyl boron alkane to obtain a mixed solution B, the weight-to-volume ratio (g / L) of tert-butylborane and phenyl ether is 42:1; the mixed solution B is heated and stirred in an oil bath for 30min, the temperature of the oil bath is 210°C, and the stirring speed is 300 rpm / min, after the reaction is finished, the system is cooled to room temperature and cleaned to obtain AgCo nanocrystals.

[0038] A method for preparing an AgCo metal nano-catalyst, comprising the steps of: drying the above-mentioned AgCo nano...

Embodiment 2

[0040] A preparation method of AgCo nano crystals, comprising the steps of: mixing 27 parts of phenylene ether, 16 parts of oleylamine, 3.5 parts of oleic acid, cobalt acetylacetonate and silver acetate in parts by volume to obtain mixed solution A, cobalt acetylacetonate and benzene The mass volume ratio (g / L) of ether is 11:1, and the mass volume ratio (g / L) of silver acetate and phenyl ether is 9:1; preheat and stir the mixed solution A in an oil bath, and then add tert-butyl boron alkane to obtain a mixed solution B, the weight-to-volume ratio (g / L) of tert-butylborane and phenyl ether is 38:1; the mixed solution B is heated and stirred in an oil bath for 35min, the temperature of the oil bath is 190°C, and the stirring speed is 350 rpm / min, after the reaction is finished, the system is cooled to room temperature and cleaned to obtain AgCo nanocrystals.

[0041] A method for preparing an AgCo metal nano-catalyst, comprising the following steps: drying the above-mentioned ...

Embodiment 3

[0043] A preparation method of AgCo nano crystals, comprising the steps of: mixing 25 parts of phenylene ether, 17 parts of oleylamine, 3 parts of oleic acid, cobalt acetylacetonate and silver acetate in parts by volume to obtain mixed solution A, cobalt acetylacetonate and benzene The mass volume ratio (g / L) of ether is 12:1, and the mass volume ratio (g / L) of silver acetate and phenyl ether is 8:1; preheat and stir the mixed solution A in an oil bath, and then add tert-butyl boron alkane to obtain a mixed solution B, the weight-to-volume ratio (g / L) of tert-butylborane and phenyl ether is 40:1; the mixed solution B is heated and stirred in an oil bath for 32min, the temperature of the oil bath is 200°C, and the stirring speed is 330 rpm / min, after the reaction is finished, the system is cooled to room temperature and cleaned to obtain AgCo nanocrystals.

[0044]A method for preparing an AgCo metal nanocatalyst, comprising the steps of: drying the above-mentioned AgCo nanocr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com