Left and right ball plate group die of solar energy water storage tank

A water storage tank and solar energy technology, which is applied to other household appliances, household appliances, metal processing equipment, etc., can solve the problems of poor surface finish in the concave area of the inner surface, unadjustable extension height of hemispherical protrusions, wrinkling, cracked edges, etc. , to achieve the effect of reasonable overall structure, good stability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

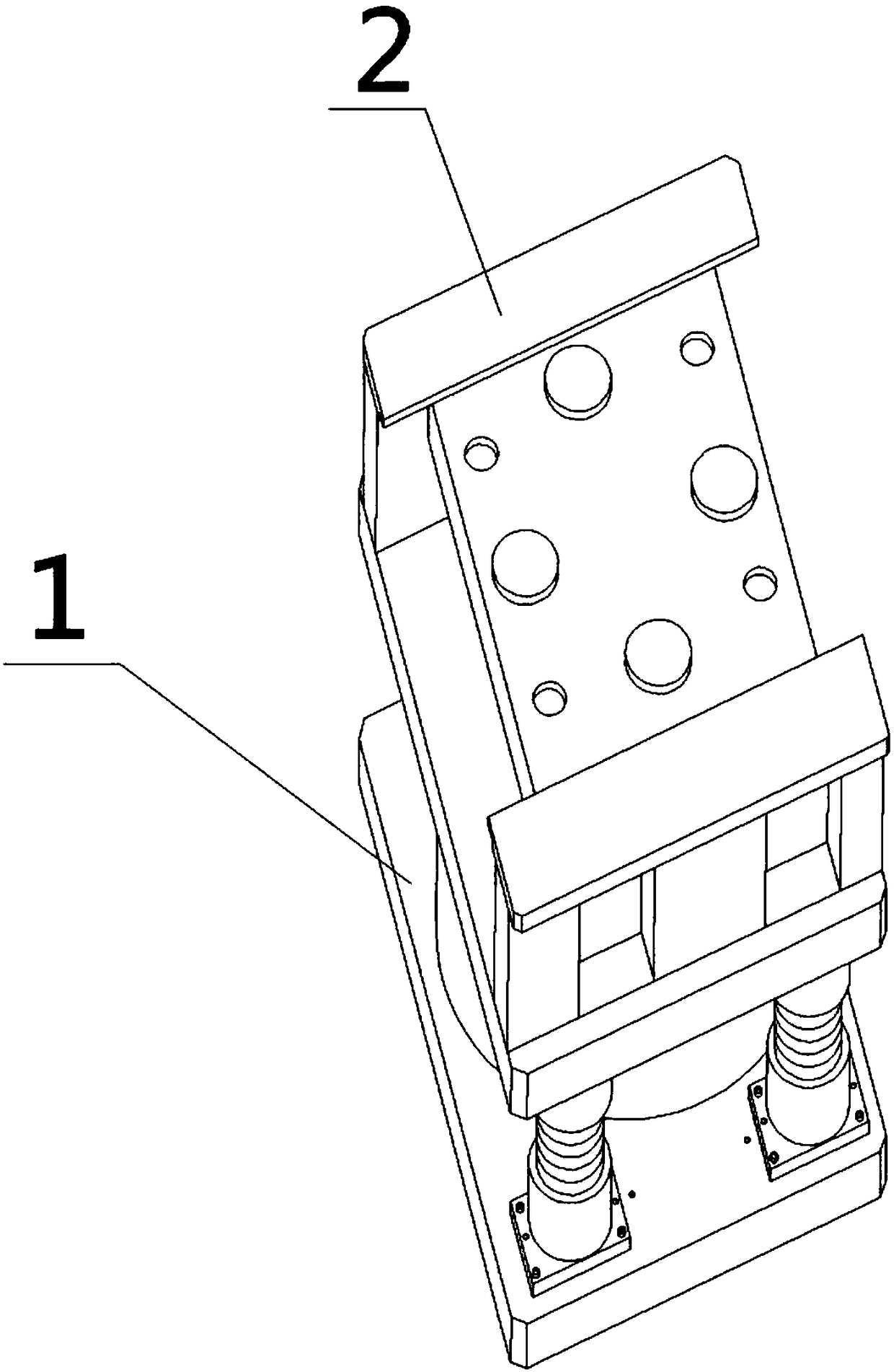

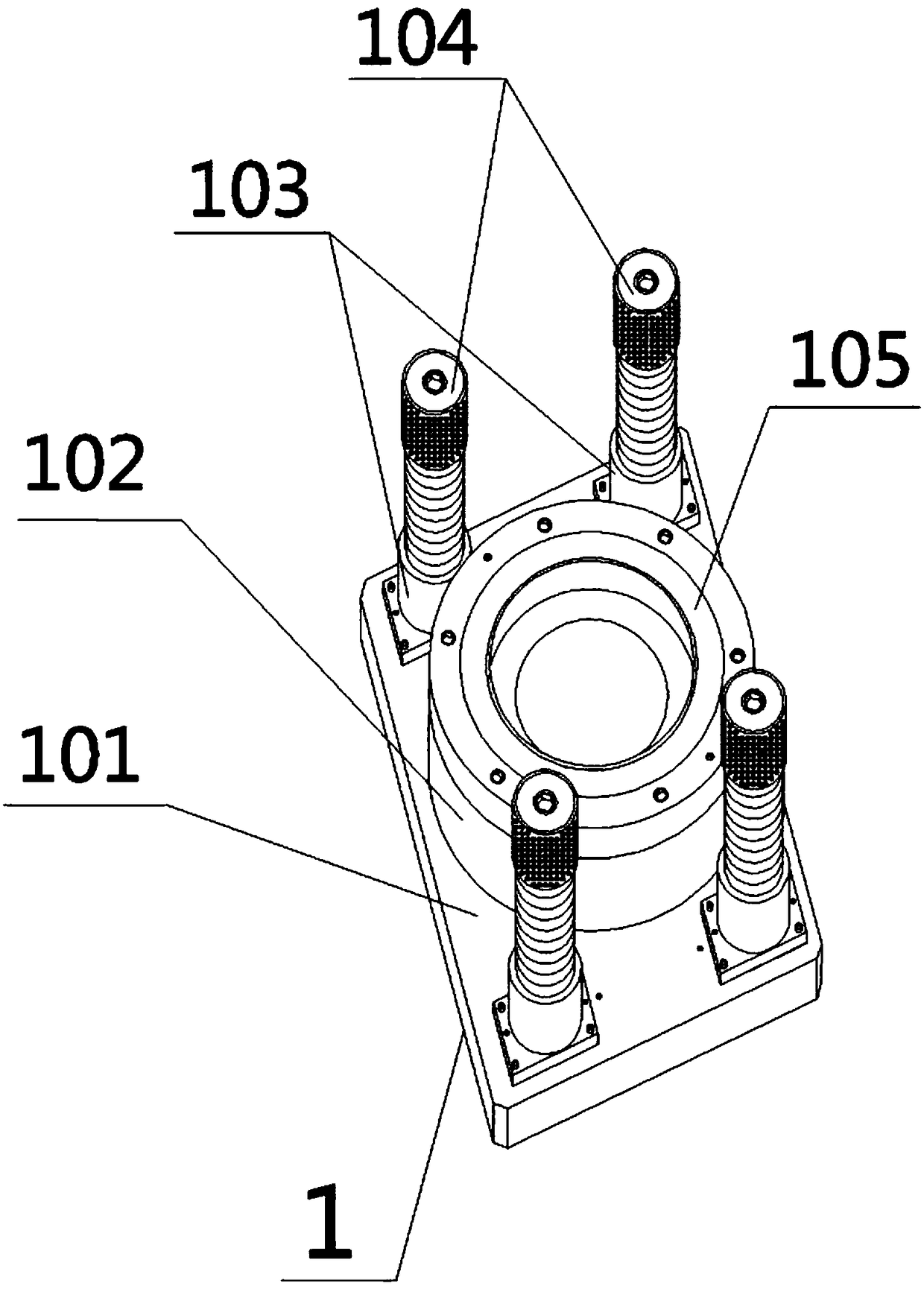

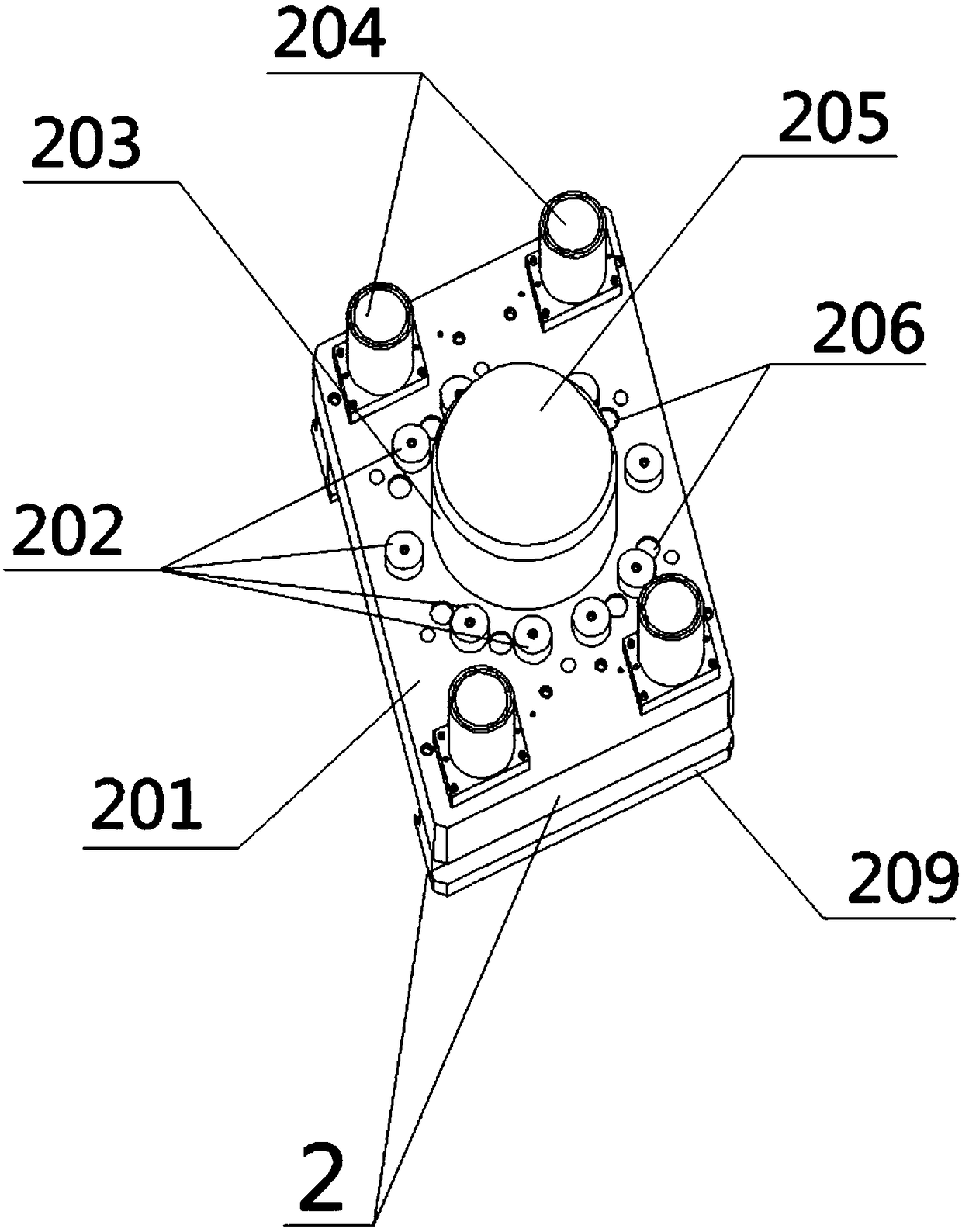

[0014] Referring to the accompanying drawings, a solar water storage tank left and right spherical panel assembly is characterized by comprising a male mold base 2 and a female mold base 1 . Described die holder 1 comprises die set plate 101, die 105, die backing plate 102, guide post 104 and guide post seat 103, and die set plate 101 is installed on the production equipment, and die backing plate 102 and die backing plate 102 Die 105 is connected integrally installed and fixed on the die fixed plate 101, the die 105 is positioned on the die backing plate 102, the guide post seat 103 is installed at the four corners of the die fixed plate 101, the guide post 104 and the guide post seat 103 are connected as It is integrally installed on the die fixing plate 101, and the guide post 104 is covered with a spring and a slidable ball sleeve. The punch base 2 includes a punch fixing plate 201, a punch 205, a punch backing plate 203, and a guide sleeve 204. , limit column 202, guide p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com