Asynchronous sliding device and foundation in-situ testing device and testing method thereof

A technology of in-situ testing and sliding device, applied in the testing of infrastructure, infrastructure engineering, construction, etc., can solve the problems of inaccurate test results, poor reliability, complicated operation, etc., and achieve the effect of ensuring reliability and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

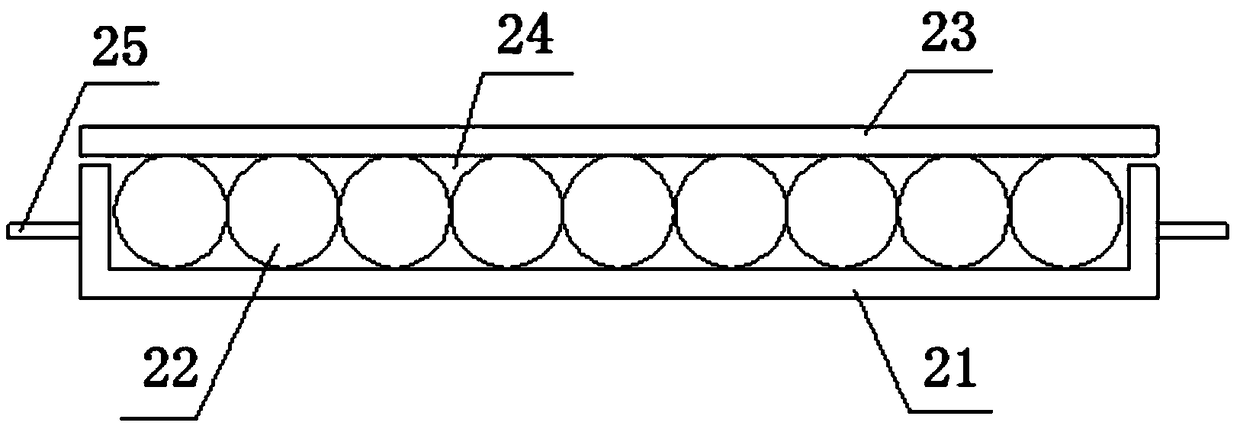

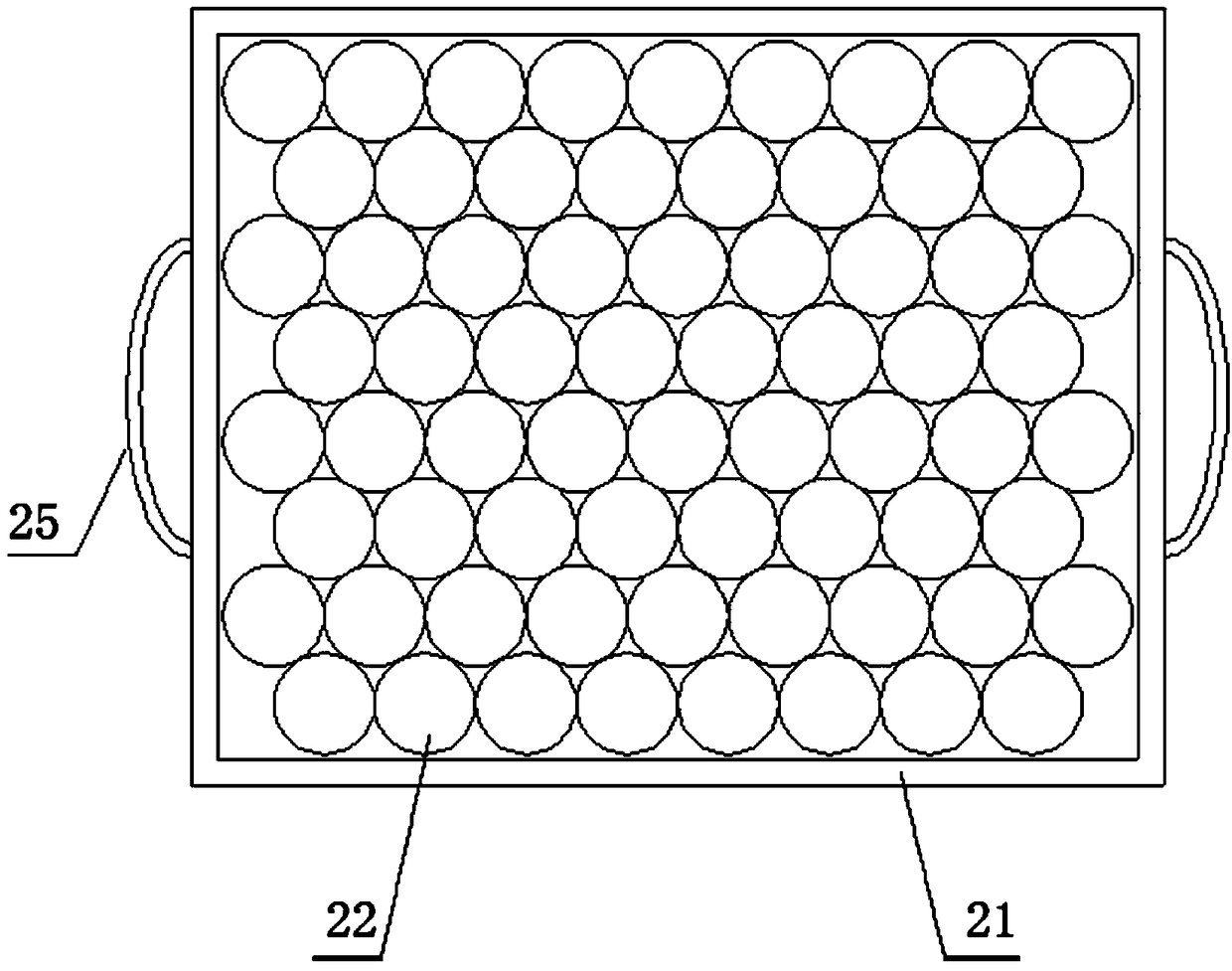

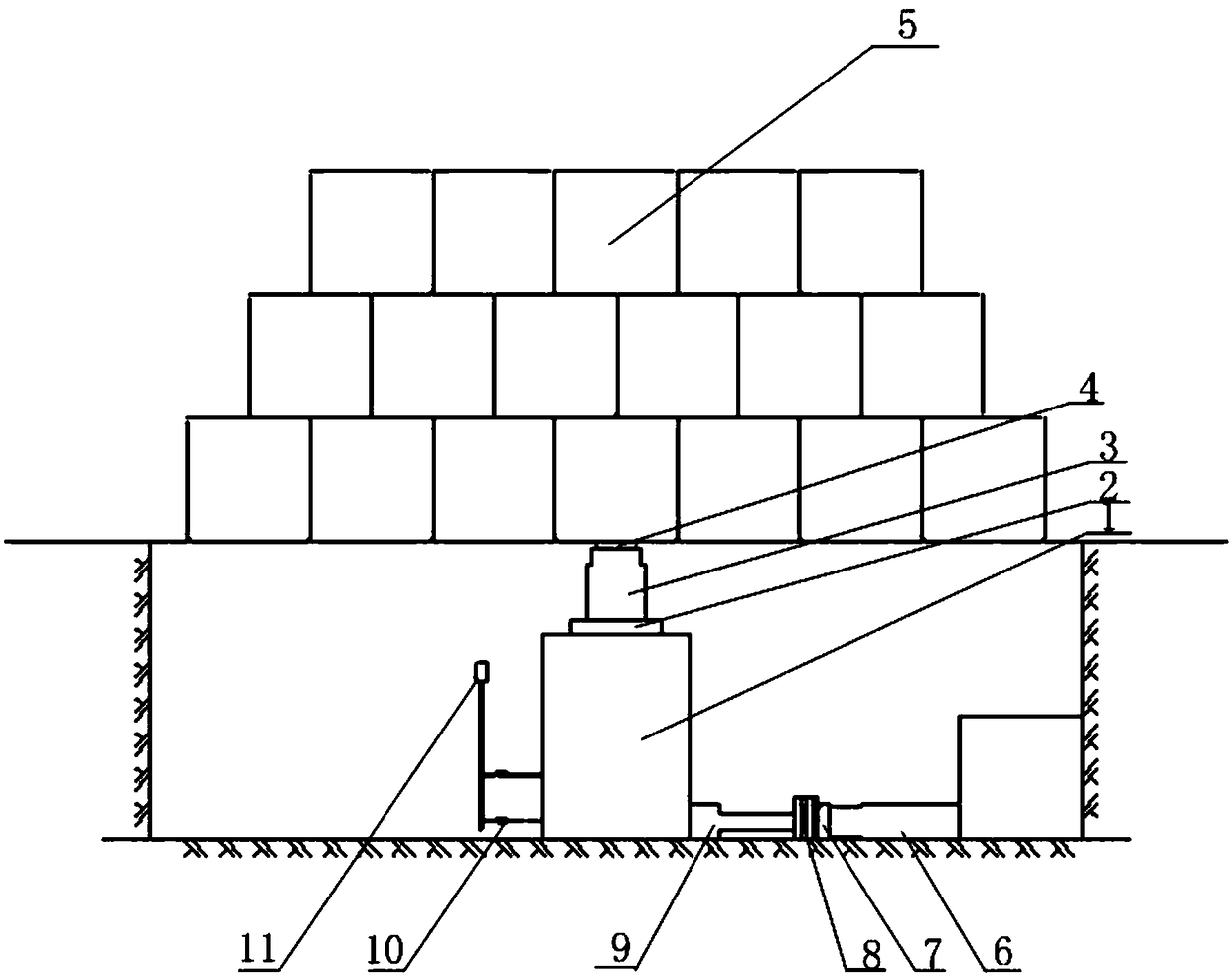

[0031] Such as figure 1 and figure 2 As shown, the asynchronous sliding device for foundation in-situ testing according to the present invention includes a belt box body 21 and a box cover 23. The box body 21 is a flat square steel box surrounded by the bottom and side walls of the box body. The box body 21 is flat inside. Lay a layer of steel balls 22 with the same diameter, and the steel balls 22 are all over the box body 21, so that they can only roll in the box body 21 and cannot move horizontally relative to the box body 21. Lid 23 is a flat plate structure, and the diameter of steel ball 22 is 2~3mm larger than the height of the side wall of box body 21, so that there is a certain gap between the side wall of lid 23 and the box body.

[0032] In this example, the box body 21 and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com