Shakeproof stable clutch assembly

A clutch and clutch cover technology, applied in the field of automobile transmission system, can solve the problems of difficulty in achieving the ideal, reducing the service life of the comfortable clutch assembly, wasting resources, etc., and achieve the advantages of reduced use cost, obvious stability advantages, and extended service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

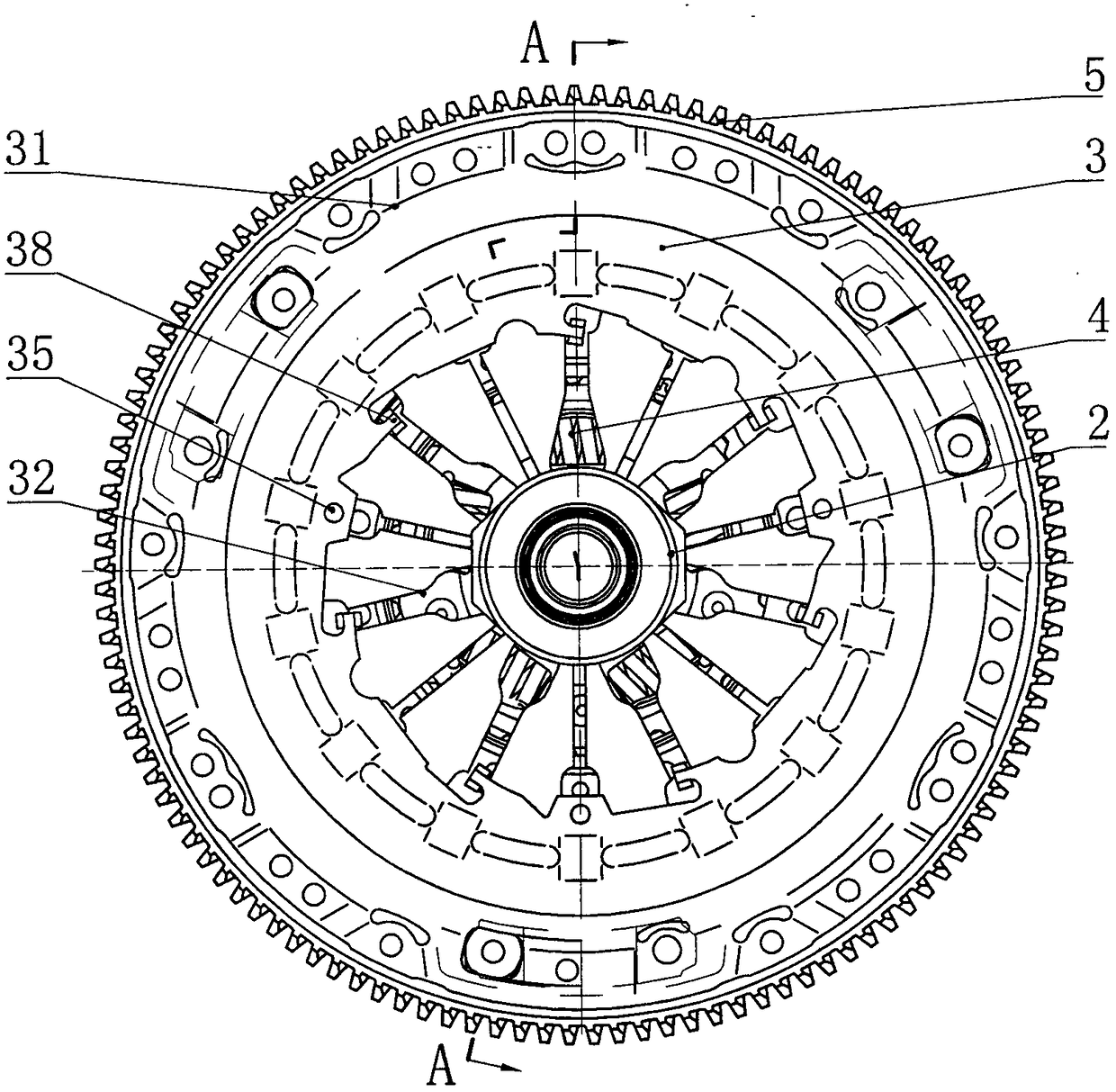

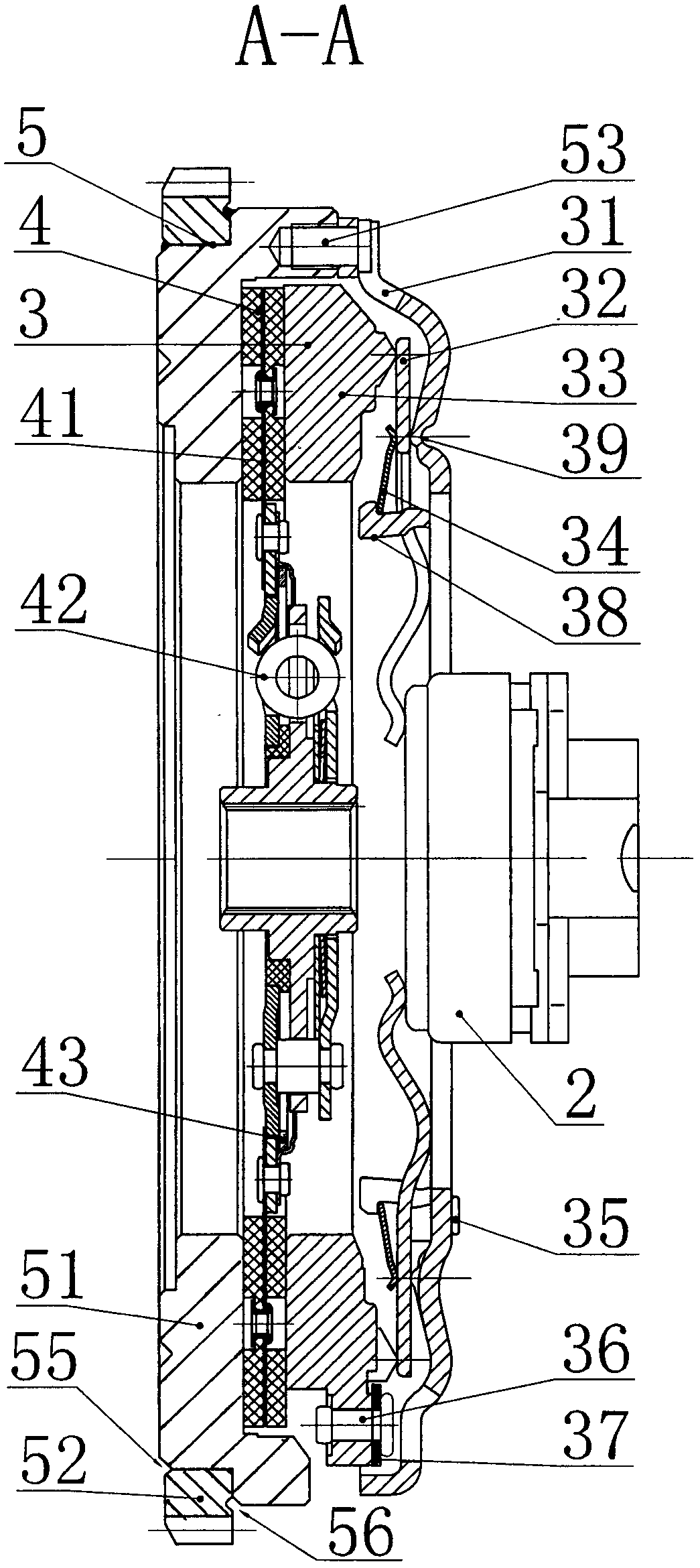

[0013] refer to figure 1 , figure 2 It can be seen that the anti-vibration and stable clutch assembly of the present invention includes a clutch cover sub-assembly 3, a driven disc sub-assembly 4, a release bearing 2, and a flywheel sub-assembly 5, and the flywheel sub-assembly 5 and the clutch cover sub-assembly The components 3 are connected by bolts 53, and the driven disc subassembly 4 is located between the big end plane of the flywheel subassembly 5 and the big end plane of the pressure plate 33 of the clutch cover subassembly 3.

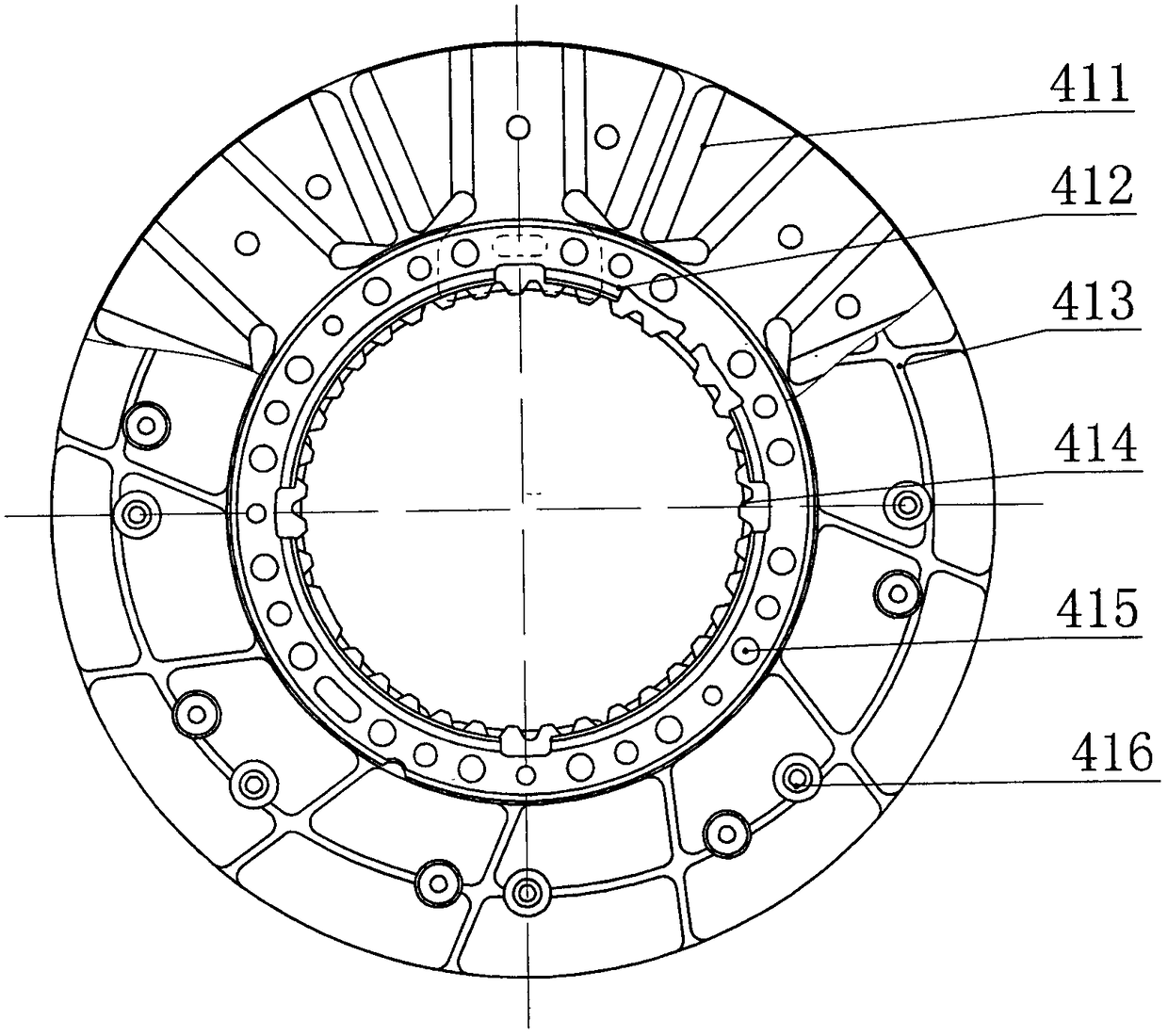

[0014] Such as figure 2 As shown, the clutch cover subassembly 3 includes a clutch cover 31, a diaphragm spring 32, and a pressure plate 33, on which a transmission plate 37 is mounted (through a rivet 36), and the clutch cover 31 has a boss Bead 39 (in a semicircular shape) is used as a support point and is on top of diaphragm spring 32 (instead of traditional support ring setting, saving parts and more compact structure), and a support r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com