State adjustment method for performance testing of multi-stage compressor with high total pressure ratio

An adjustment method and compressor technology, which are applied in the testing, measuring devices, instruments and other directions of machines/structural components, can solve problems such as undiscovered, achieve the effect of simple method, expand test ability, and ensure smooth development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below by means of specific embodiments:

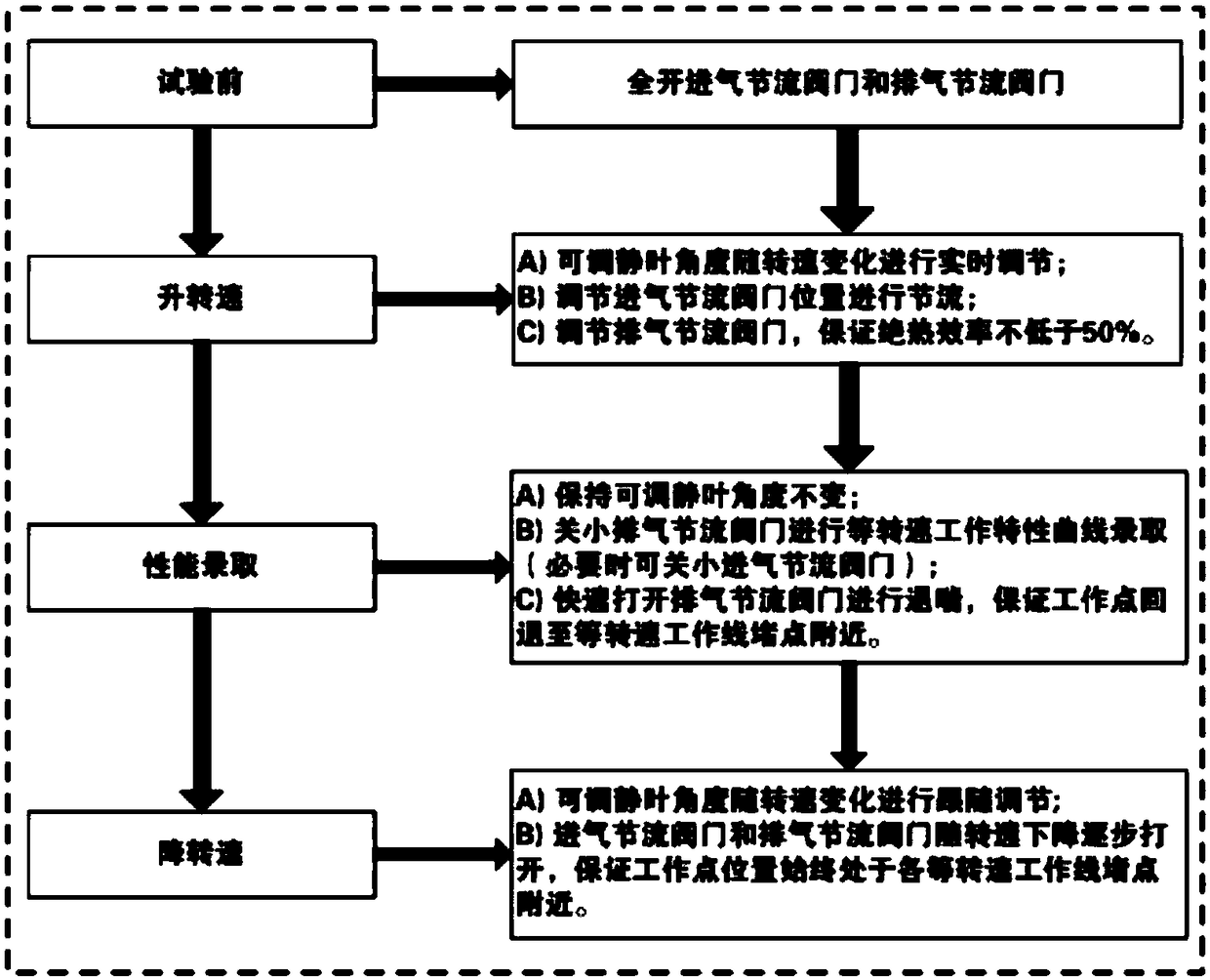

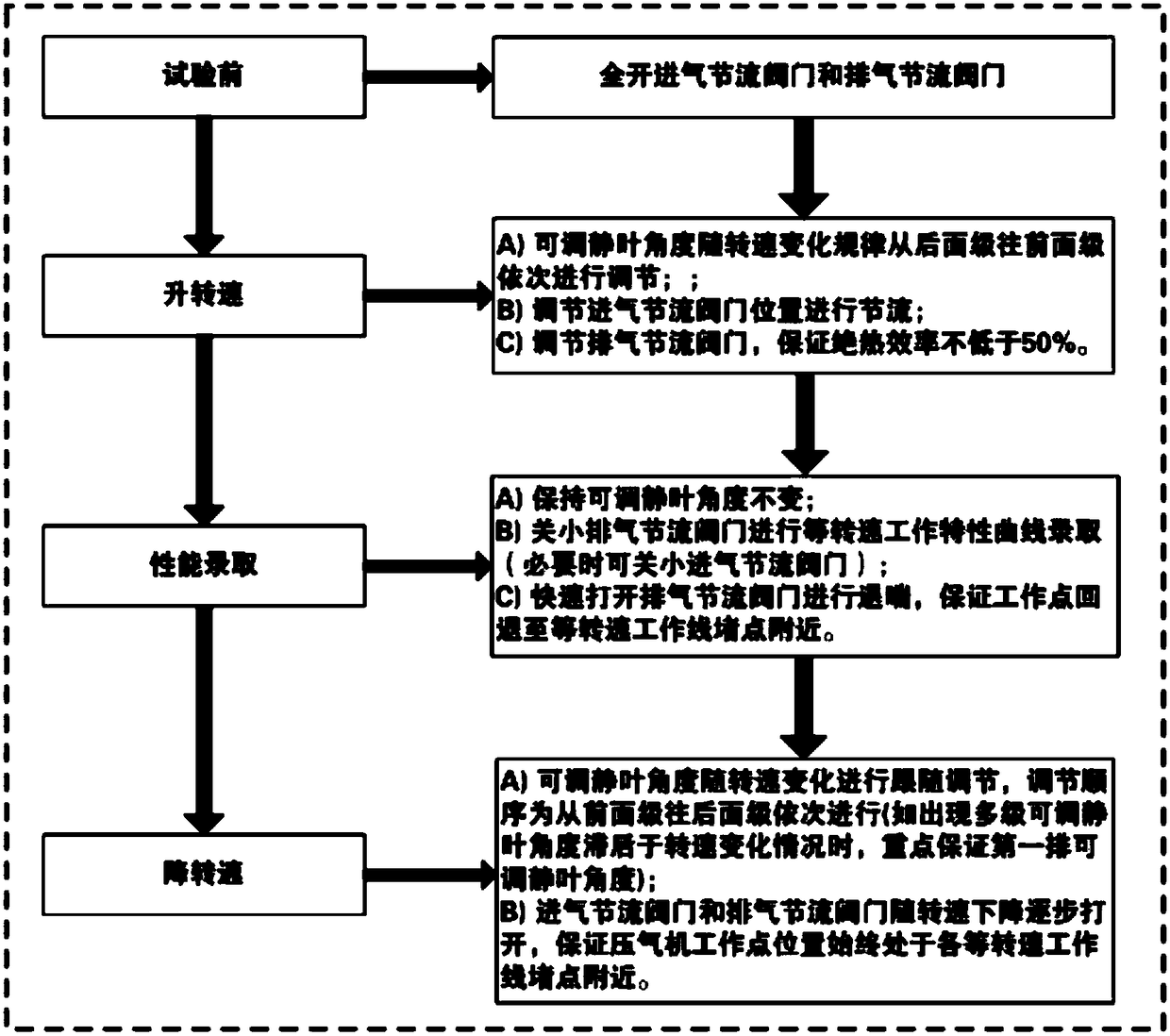

[0032] The state adjustment method of performance test of high total pressure ratio multi-stage compressor involves four adjustment parameters: compressor speed, compressor adjustable vane angle, tester inlet throttle valve opening and exhaust throttle valve opening . During the test, the real-time and precise control of the matching working state of the compressor was realized through the combined and coordinated adjustment of the above four physical parameters. According to the specific structure of the compressor test piece, the adjustable vane angle can be divided into the following two situations: joint adjustment of multiple rows of vanes and individual adjustment of multiple rows of vanes. When multiple rows of stator blades are jointly adjusted, the ratio relationship of each row of adjustable stator blade angles is determined by the compressor stator blade angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com