Optical cable sealing structure with elastic extrusion sealing function

A technology of extrusion sealing and sealing structure, which is applied in the direction of fiber mechanical structure, light guide, optics, etc., can solve the problems of shrinking volume, reducing sealing performance, large temperature change, etc., and achieves the effect of fast installation and fixing and ensuring sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

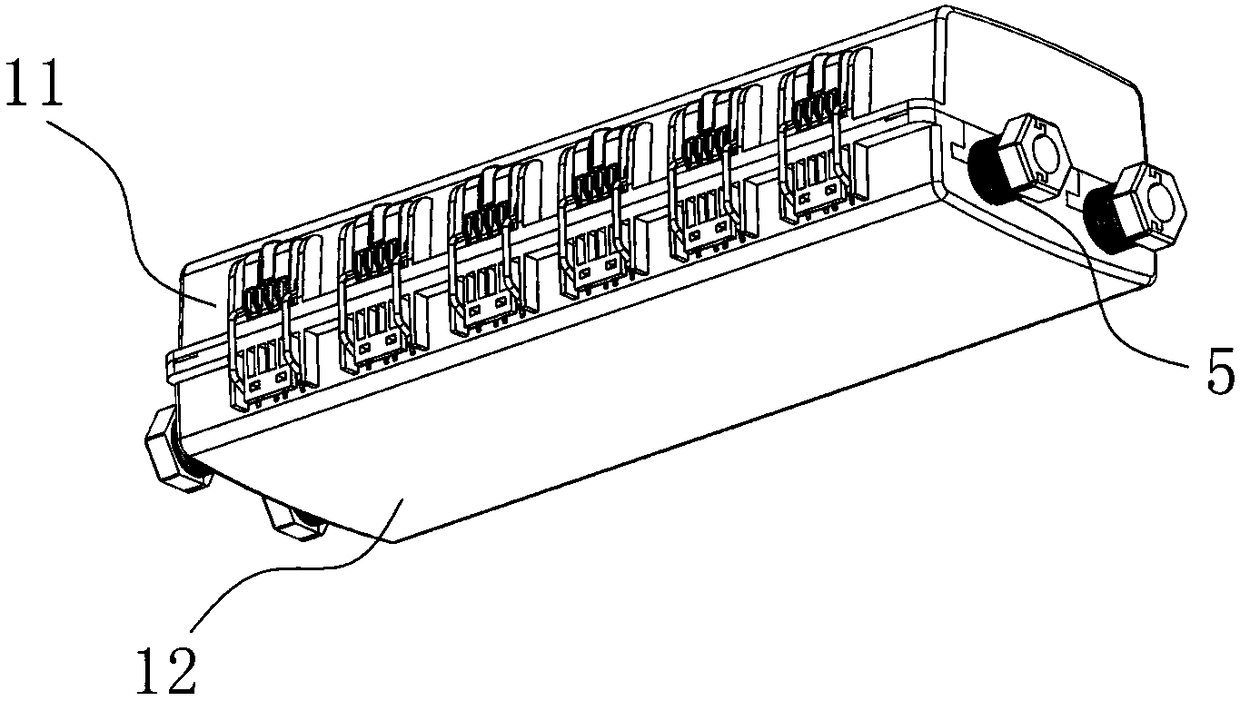

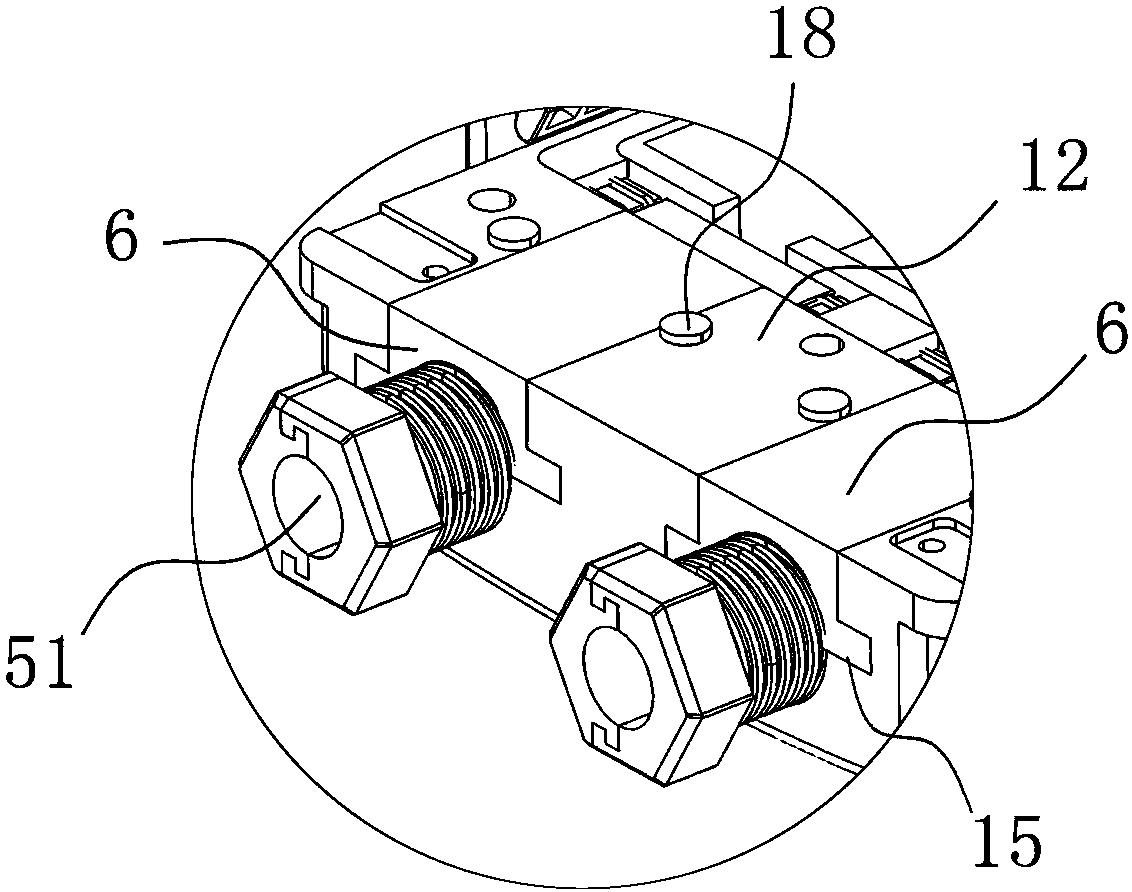

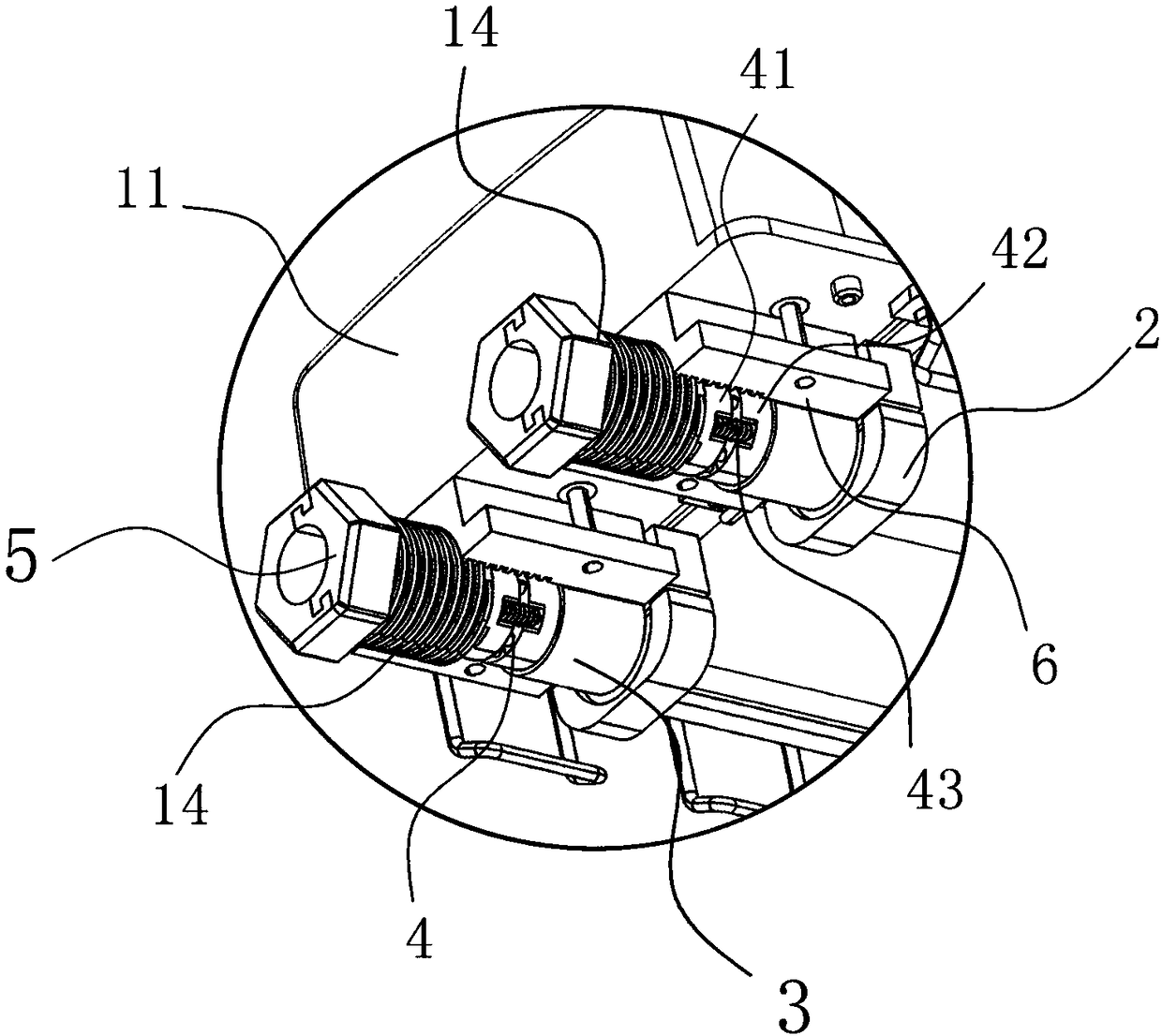

[0029] see Figure 1-Figure 12 , the present embodiment has the optical cable joint closure of elastic extrusion sealing function, comprises upper box body 11 and lower box body 12, and the both sides of optical cable joint box have the optical cable embedding hole 13 that is used to pass through optical cable, and described optical cable is embedded The hole 13 is sequentially provided with a retaining ring 2, an elastic sealing ring 3, an elastic extrusion module 4 and an extrusion bolt 5 from the inside to the outside. The extrusion bolt 5 has a perforation 51 for passing through the optical cable. The elastic extrusion module 4 includes a front Connector 41, rear connector 42 and stage clip 43, front connector 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com