Partial section closure device with positive-negative air-pressure double channels

A closed device, dual-channel technology used in packaging, liquid bottling, transportation and packaging to solve problems such as deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

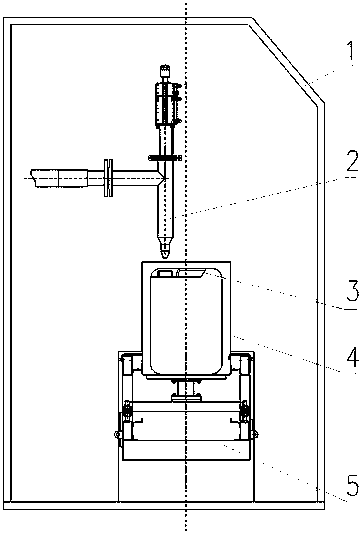

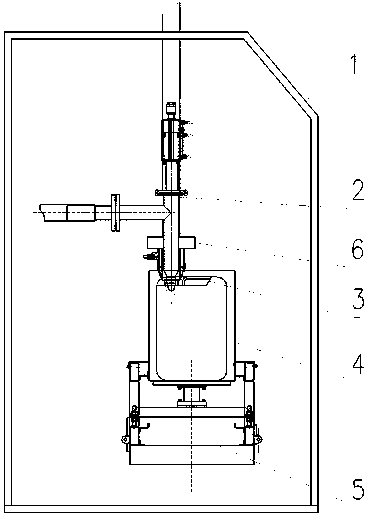

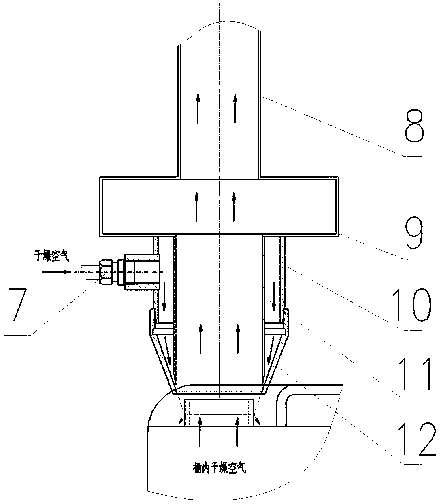

[0016] The utility model will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

[0017] The purpose of the present invention is to effectively solve the problem that during the filling process of the filling equipment, a large amount of air containing water vapor enters the filling room to react with materials and deteriorate. The present invention utilizes the dry inert gas or the gas flow formed by other gases that do not react chemically with the material to isolate the contact between the air containing water vapor and the material, so as to realize the closed filling filling device and the closed filling technology. To ensure that chemical raw materials are not polluted during the filling process, and that no chemical reactions occur that affect their normal sales and use.

[0018] The present invention has a local area sealing device with positive and negative wind pressure dual channels, the specific struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com