Lift type steel trestle device for warehousing roller compacted concrete

A roller compacted concrete, lifting technology, applied in the direction of bridges, vertical bridges, bridge forms, etc., can solve the problems of restricting the construction progress, slow rolling concrete entering the warehouse, and the elevation cannot be kept consistent at any time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

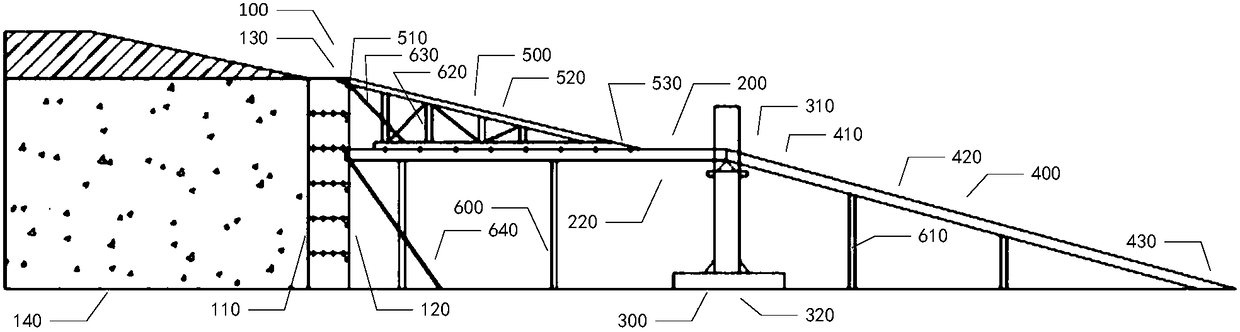

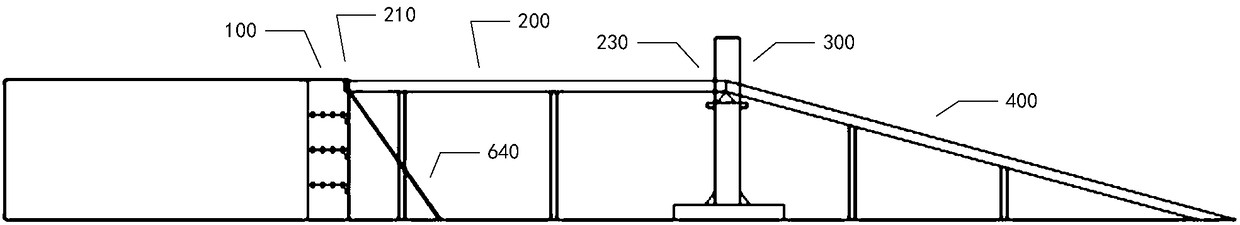

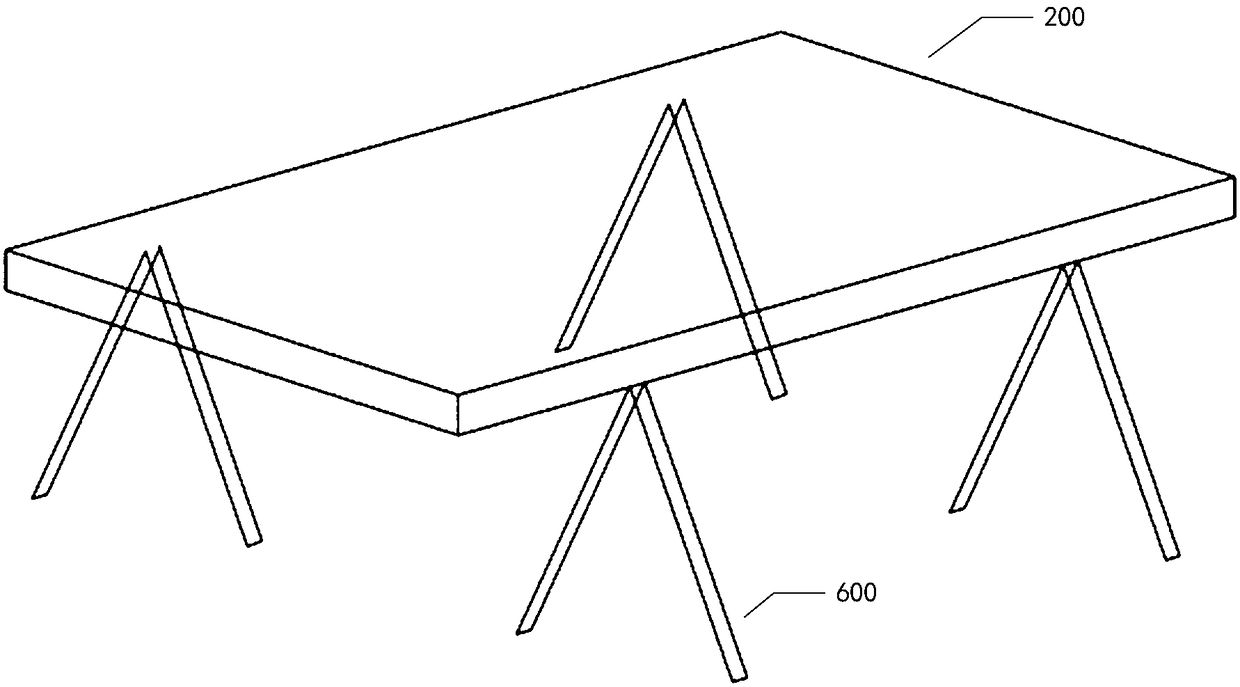

[0029] The present invention discloses a lift-type steel trestle device for rolling concrete into a silo. The first fastening surface 110 of the prefabricated block 100 is fixedly connected to the concrete platform 140; the first end 210 of the first bridge body 200 It is fixedly connected with the second fastening surface 120 of the prefabricated block 100, the second end 230 of the first bridge body 200 is fixedly connected with the third end 410 of the second bridge body 400, and supports the fourth end 430 of the second bridge body 400 on the ground. Then, the fifth end 510 of the third bridge body 500 is fixedly connected with the connecting end 130 of the prefabricated block 100 , and the sixth end 530 of the third bridge body 500 is fixedly connected with the first body 220 of the first bridge body 200 . Since the second end 230 of the first bridge body 200 and the third end 410 of the second bridge body 400 are connected to the second end 230 of the lifting mechanism 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com