Concrete fast warehousing system and method

A concrete and fast technology, which is applied in the field of warehousing system, concrete quick warehousing and concrete quick warehousing system, can solve the problems of low efficiency and achieve the effect of speeding up warehousing, improving safety and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

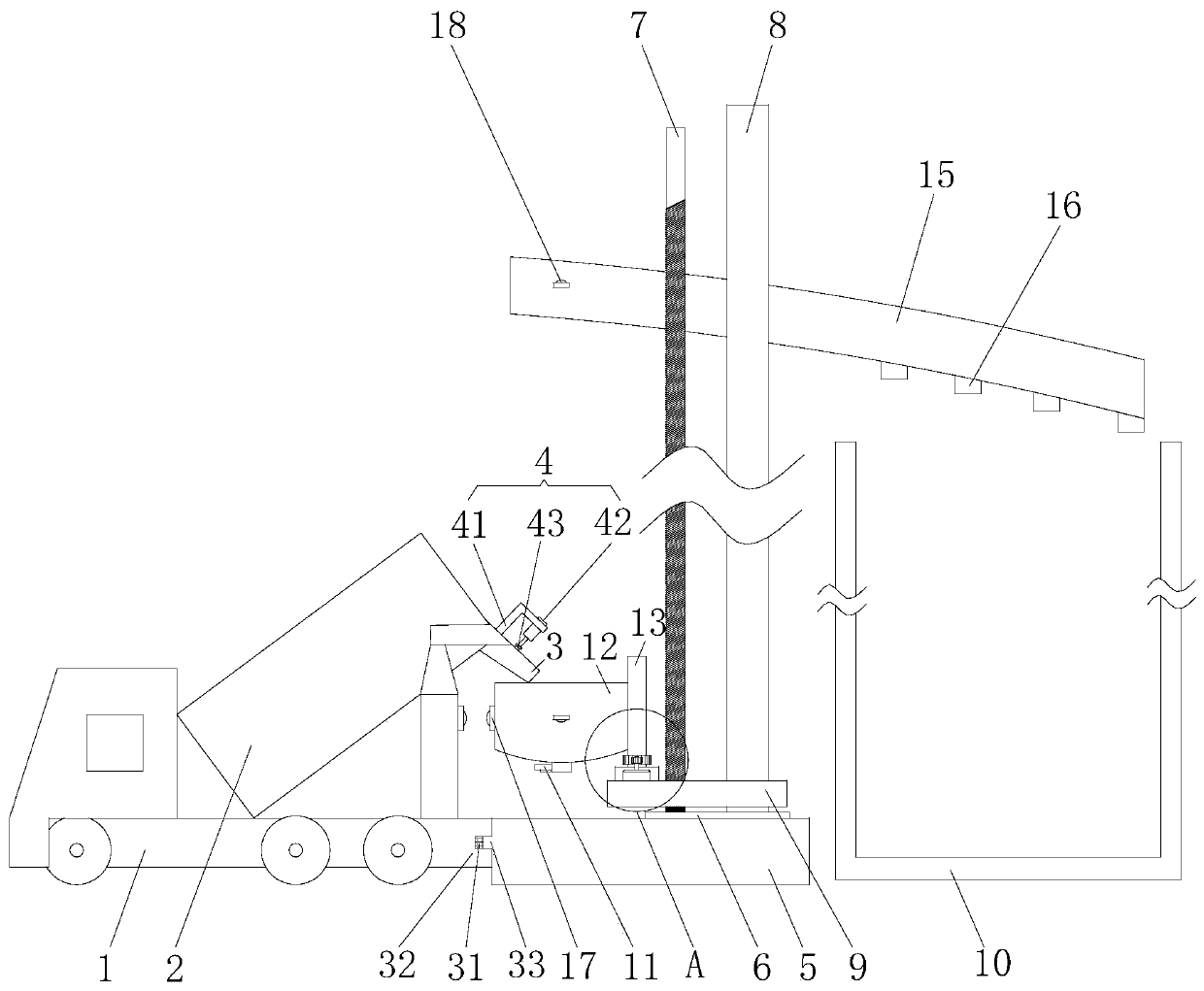

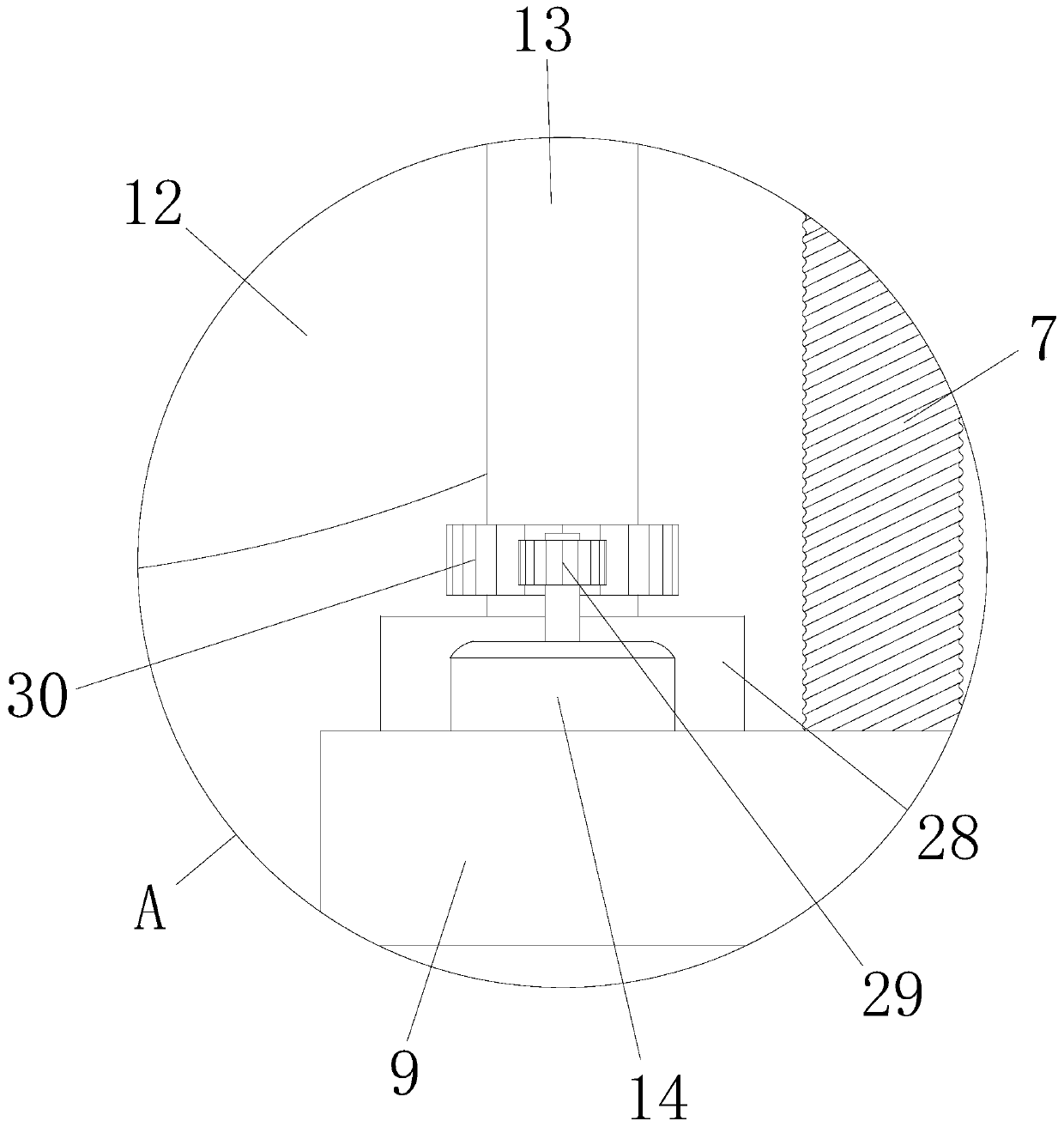

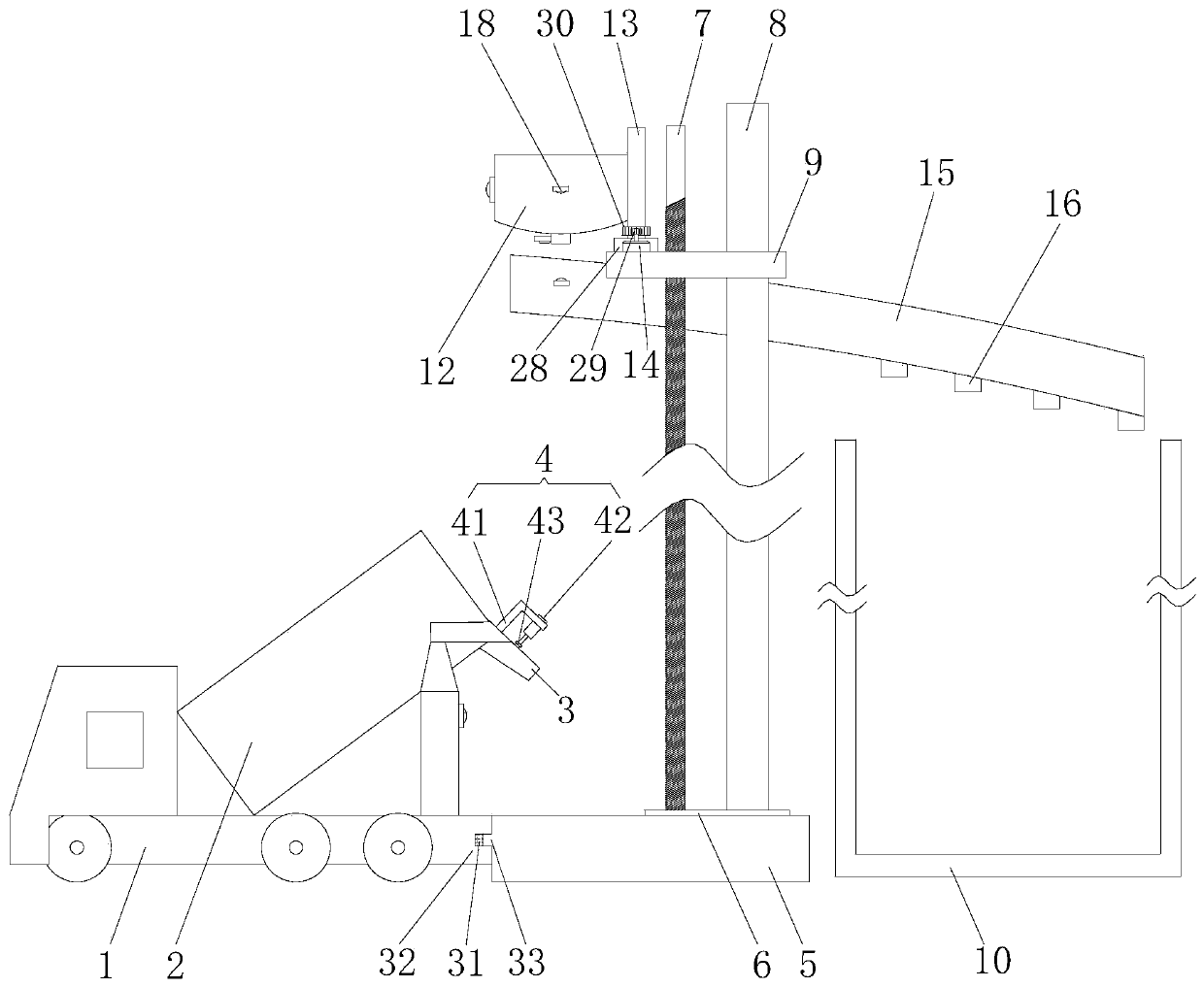

[0074] see figure 1 , figure 2 as well as image 3 , the present embodiment provides a quick concrete binning system, which is used to send concrete into the pouring bin 10, especially to send concrete into some particularly high pouring bins 10. Wherein, the concrete quick warehousing system includes a storage device, a moving device and a feeding device. The material storage device is used to store concrete, and the mobile device is used to transport the material storage device to the side of the pouring bin 10 , and the feeding device can further send the concrete in the material storage device into the pouring bin 10 .

[0075] The mobile device includes a transport vehicle 1, and may also include other equipment, such as gravity detection equipment. The transport vehicle 1 is used to transport the storage device, and it can adopt large transport vehicles such as existing trucks. The transport vehicle 1 can transport the material storage device to the concrete product...

Embodiment 2

[0091] see Figure 4 , Figure 5 as well as Figure 6 , this embodiment provides a concrete storage system quickly, which adds a touch-press part 19 and a touch-press switch 20 on the basis of the first embodiment. Among them, among the alignment structure 1 32 and the alignment structure 2 33 , one is provided with a contact portion 19 , and the other is provided with a contact switch 20 . When the transport vehicle 1 is in limited position with the base 5 , the pressure contact portion 19 abuts against the pressure switch 20 , so that the pressure switch 20 sends out a trigger signal for driving the controller to open. In this embodiment, the pressing portion 19 has an elastic end, and the elastic end includes a spring 34 and a pressing block 35 , and the pressing switch 20 is installed on the positioning block 36 . One end of the touch block 35 is connected to the spring 34 , and the other end is close to the touch end of the touch switch 20 . In this way, the controlle...

Embodiment 3

[0093] This embodiment provides a concrete storage system quickly, which adds a load cell on the basis of Embodiment 1. Wherein, the weighing sensor belongs to the detection mechanism, and the weighing sensor is installed between the feeding hopper 12 and the driving shaft 13, and is used for detecting the weight of the concrete in the feeding hopper 12. When the weight detected by the load cell is greater than a preset weight, the controller drives the discharge switch 4 to close. When the weight detected by the load cell is less than a preset weight 2, the controller determines that the concrete in the feeding hopper 12 is put into the storage pipe 15, and makes the feeding hopper 12 rotate. According to the weight data detected by the load cell, the controller can consider that the feeding hopper 12 is full of concrete when the weight is greater than the preset weight one, and the discharge switch 4 can be closed at this time, and when the weight is less than the preset wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com