Ultrasonic probe calibration device and method for calibrating ultrasonic probe

A calibration device, ultrasonic technology, applied in the re-radiation of sound waves, measuring devices, re-radiation of electromagnetic waves, etc., can solve the problems of difficult ultrasonic probe calibration, complex structure of binocular vision measurement system, etc., to reduce calibration work and simple structure , the effect of easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

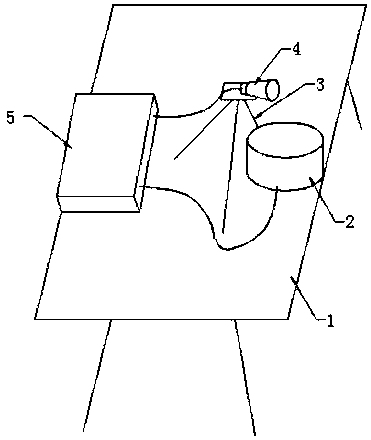

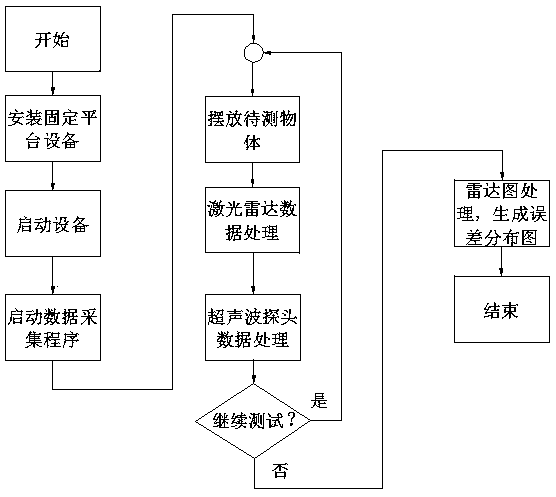

[0031] Such as Figure 1-2 As shown, an ultrasonic probe calibration device includes a fixed platform 1, which is characterized in that a laser radar 2, an ultrasonic probe fixed bracket 3 and a data acquisition device 5 are installed on the fixed platform 1, and an ultrasonic probe 4 is connected to the upper end of the ultrasonic fixed bracket 3 , the laser radar 2 and the ultrasonic probe 4 are electrically connected to the data acquisition device 5 respectively.

[0032] The fixed platform 1 is made of hard materials, the height of the fixed platform 1 is at least 0.5 meters, and the size of the platform is at least 0.3 meters × 0.5 meters, so as to ensure that other devices can be placed. The ultrasonic probe fixing bracket 3 is made of hard material, and there is a suitable fixing device on its top, which is used to fix the ultrasonic probe to be calibrated to ensure that the direction of sound wave emission is horizontal. LiDAR 2 is a rotating LiDAR or a solid-state Li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com