Bolt detection system and implementation method thereof

A detection system and implementation method technology, applied in neural learning methods, image data processing, image enhancement and other directions, can solve problems such as low reliability, hidden safety hazards, and difficulty in cost-consuming maintenance, so as to improve reliability and reduce labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

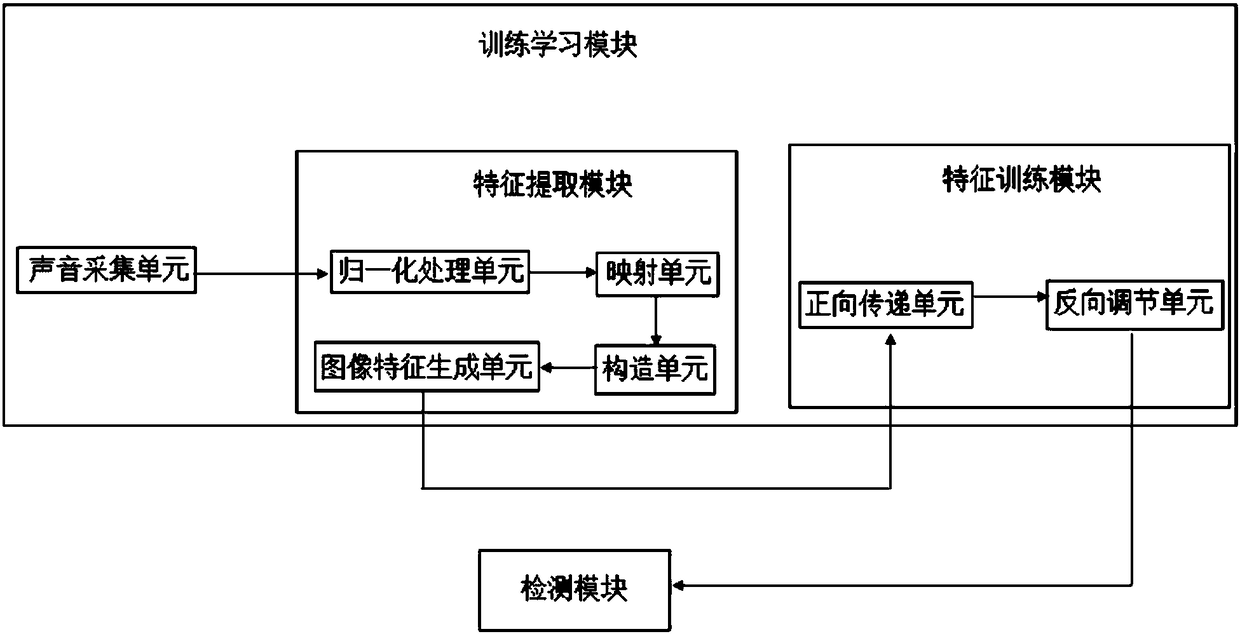

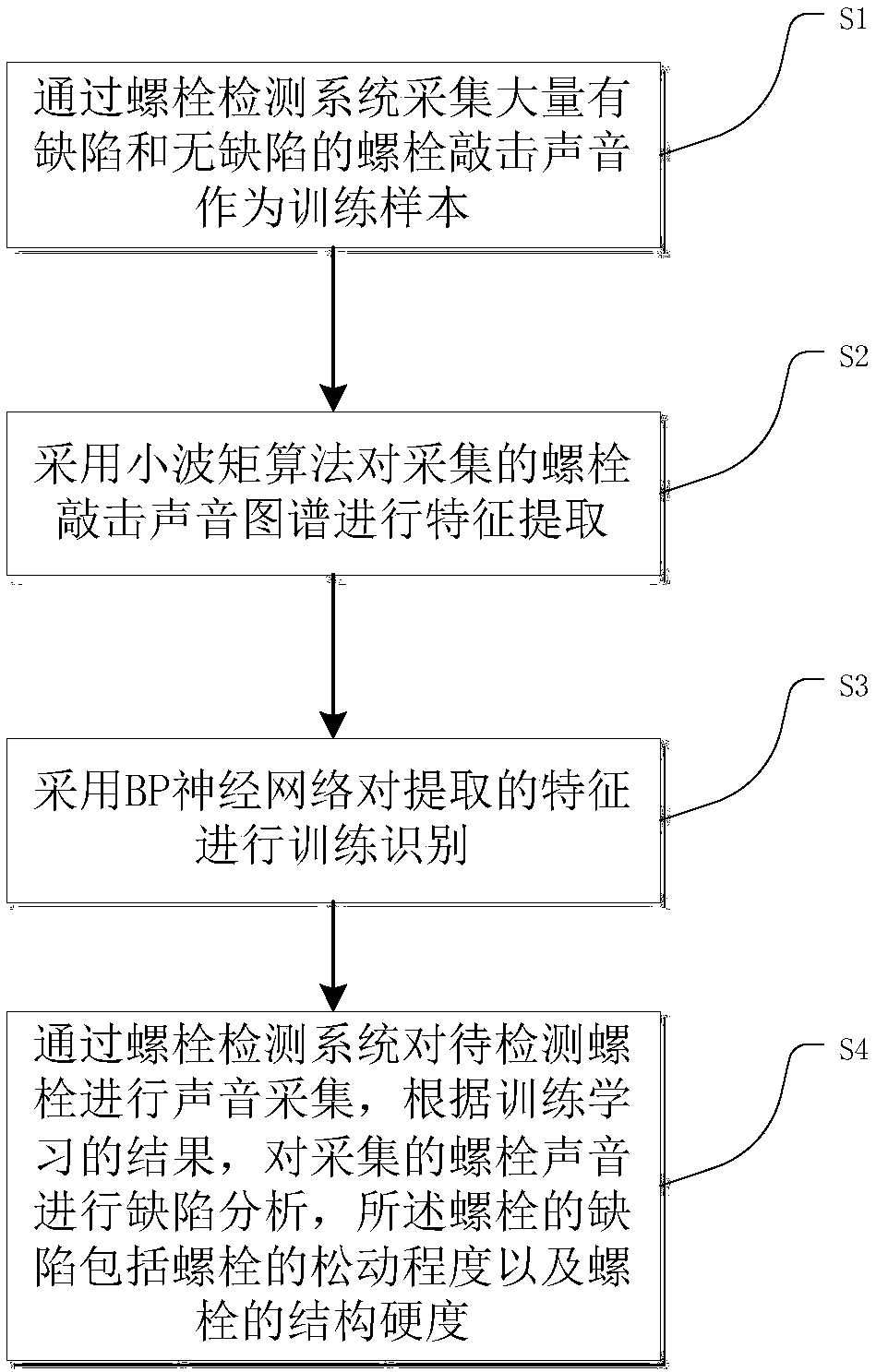

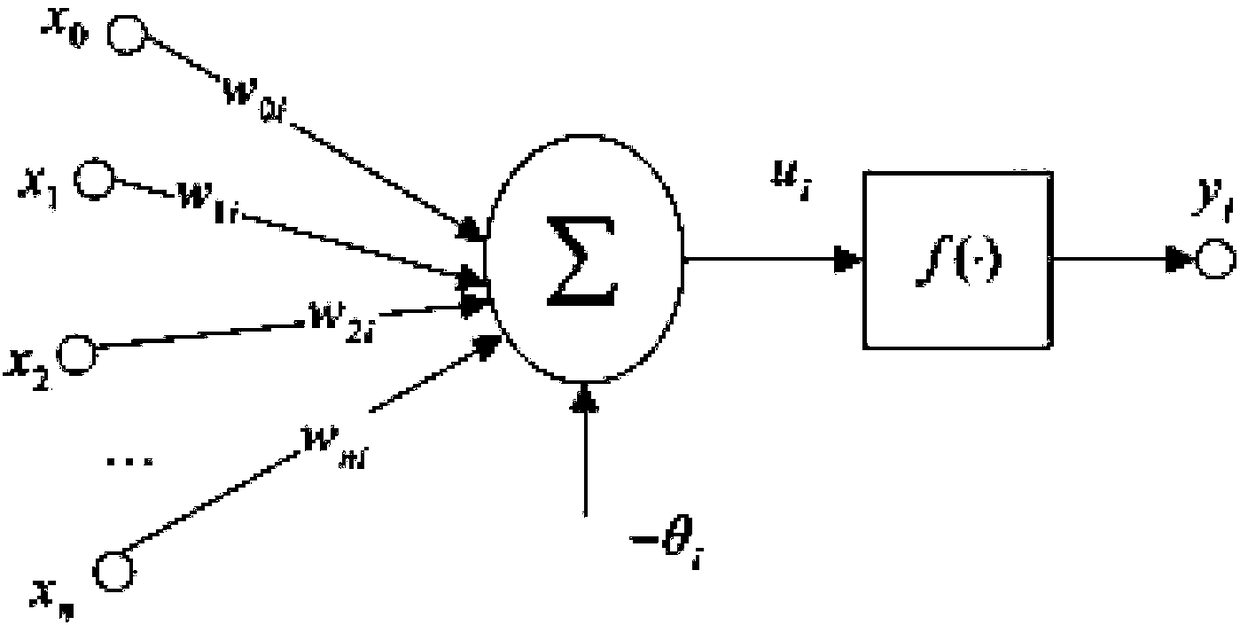

[0094] Since the current preventive inspection methods for high-strength bolts at large steel structure nodes are only observation and small hammer knocking, and this method has disadvantages such as high cost, low reliability, and lack of quantitative indicators, so the present invention proposes A bolt detection system and its realization method. The invention first extracts the features of the bolt knocking sound through the training and learning module, and trains and learns the extracted features according to the machine learning algorithm, and then performs defect detection on the bolts to be detected through the detection module. The whole working process does not require human intervention, which greatly reduces the Labor cost and improved detection reliability; in addition, the present invention can perform feature extraction and training and learning on a large number of bolt knocking sounds. Compared with the existing small hammer knocking method, the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com