Plant repair method for tailings rich in heavy metals

A phytoremediation and heavy metal technology, which is applied in application, soil preparation methods, agricultural machinery and implements, etc., can solve the problems of long duration of damage, damage to the ecological environment, high content of heavy metals, etc., and achieve the effect of being suitable for large-scale restoration and easy application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] Embodiment 1, a kind of phytoremediation method that is rich in heavy metal tailings, comprises the following steps:

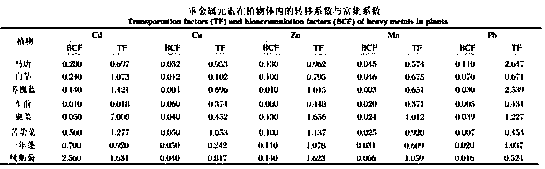

[0009] Step 1. Plant the first tolerant plant population according to the density of 15 to 35 plants per square meter. The first tolerant plant population includes any two or more of Sagelan, Dipsacanthus, Kumai, and Nest. More than two species; the four plants in the first tolerant plant group, Suguilan, Dipsacanthus, Kumaicai, and Niaocai, have high transfer coefficients for Cu, Zn, Cd, and Pb and have strong enrichment capabilities. The transfer coefficient refers to the ratio of the heavy metal content in the aboveground part of the plant to the underground part, and is usually used to measure the transport capacity of plants for heavy metals.

[0010] Step 2, planting a second tolerant plant population at a density of 10-20 per square meter, the second tolerant plant population is 3-5 months later than the first tolerant plant population, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com