Manufacturing method of waterproof shoes capable of protecting toes

A production method and technology for waterproof shoes, applied in the field of shoes, can solve the problems of high cost, cumbersome process flow, etc., and achieve the effects of excellent waterproof performance, comfortable wearing and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

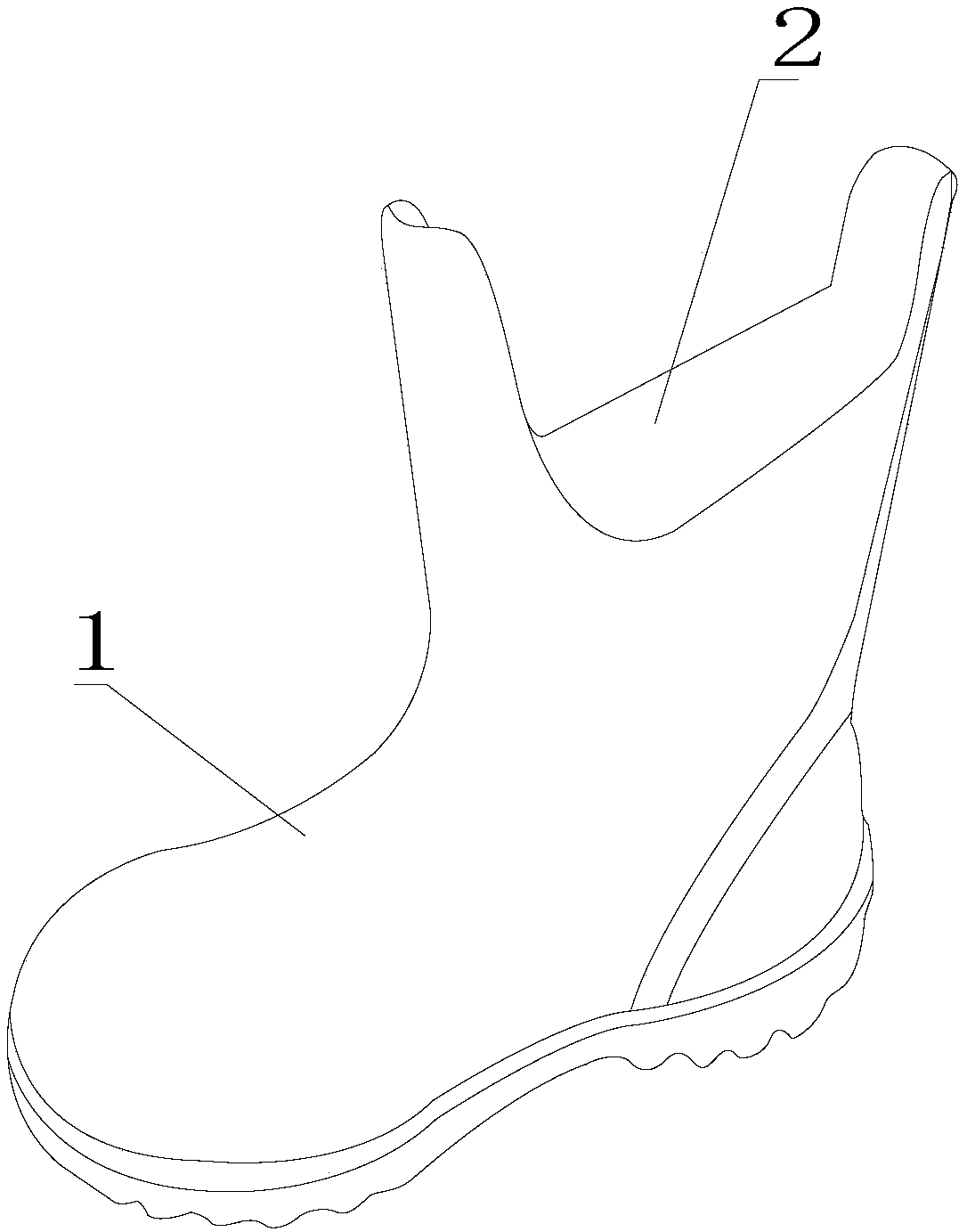

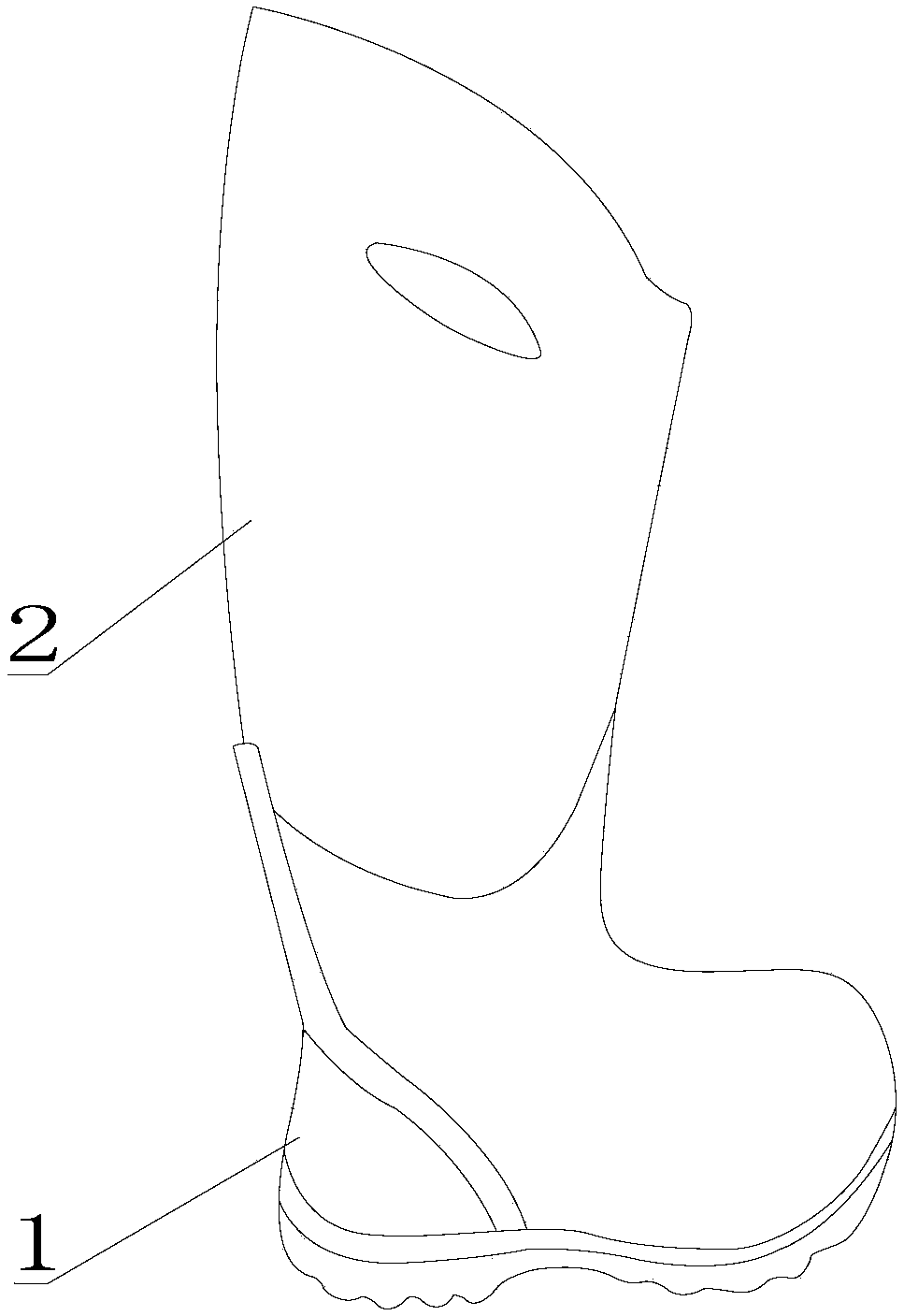

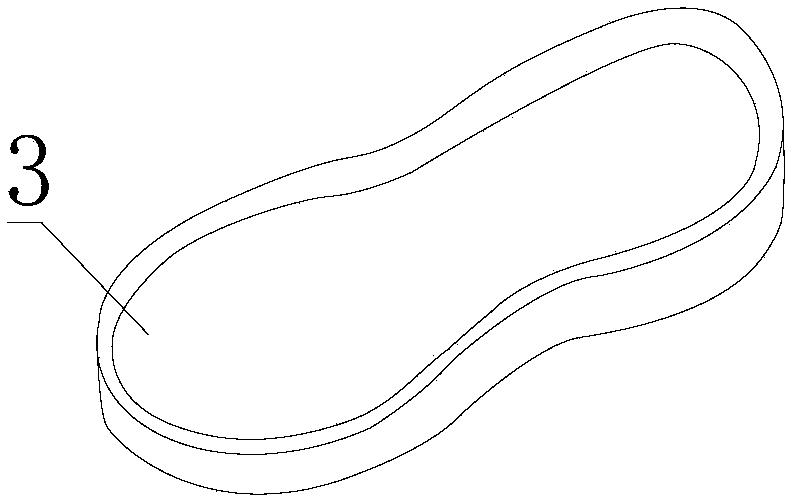

[0027] see Figure 1-Figure 3 , is the waterproof shoe that is prepared by a kind of manufacturing method of the present invention, and the manufacturing method of waterproof shoe of the present invention comprises: preparing shoe shell 1 in the mode of integral molding, and this shoe shell 1 comprises sole and vamp; After the inner surface of 1 is coated with cold glue, the shoe shell 1 is subjected to the first drying treatment; the cloth is cut out to form the bottom of the sock and at least one body part of the sock, and the bottom of the sock and each body part of the sock are combined into a sock 2 using an adhesive; Carry out the second drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com