Novel overhung telescopic welding machine

A welding machine and suspension technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low efficiency and high fatigue strength, and achieve the effect of reducing labor intensity, reducing fatigue degree and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

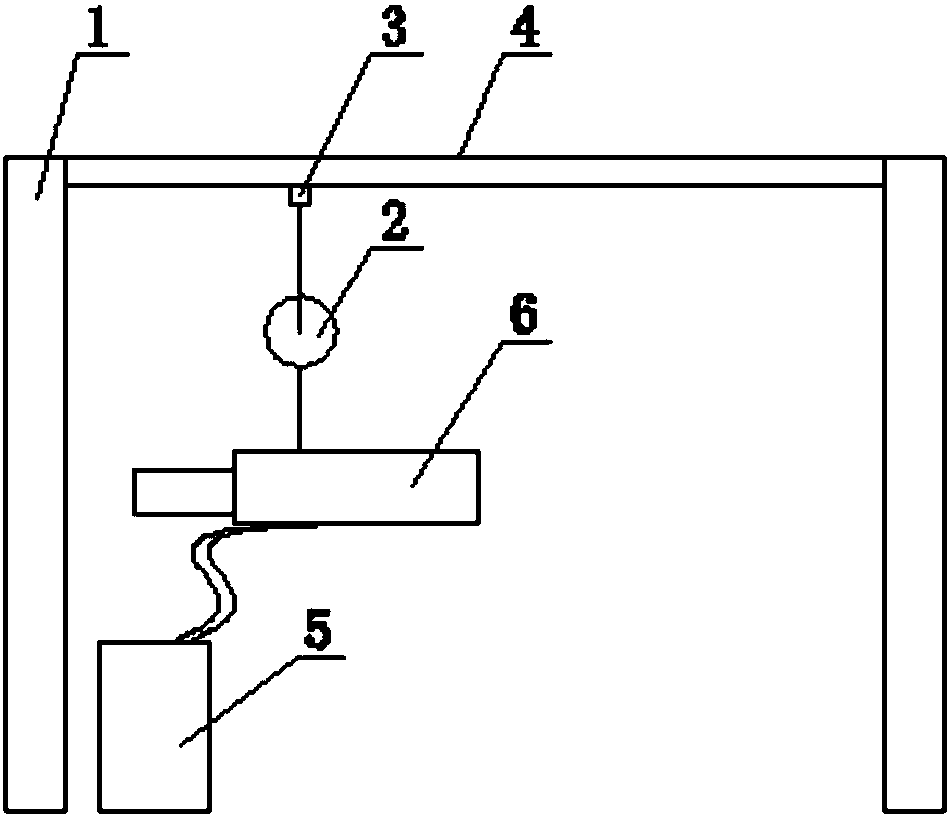

[0016] A new type of suspension telescopic welding machine, including a hand-held welding torch 6, a balancer 2, a moving slide rail 3 and a connecting piece 4, the connecting piece is installed on the workstation frame or the beam 1 of the factory building, and the moving slide rail is installed on the connecting piece, The balancer is installed on the moving slide rail, and the lower end of the balancer is connected with a hand-held welding torch through a suspension ring, and the hand-held welding torch is connected with the welding controller 5 .

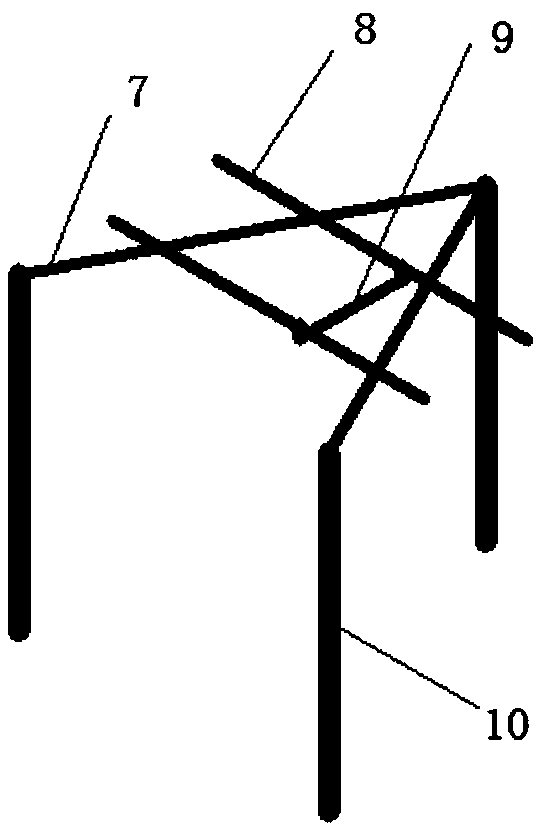

[0017] The connectors include three 160mm I-steel support columns 10, two 100mm I-steel connecting beams 7, two 100mm I-steel beams 8, one 100mm I-steel longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com