Board punching device

A punching device and board technology, which is applied to wood processing equipment, fixed drilling machines, bark area/debris/dust/waste removal, etc., can solve the problem of low work efficiency, lower punching efficiency and quality, and affect wood punching Hole quality and other issues, to achieve the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

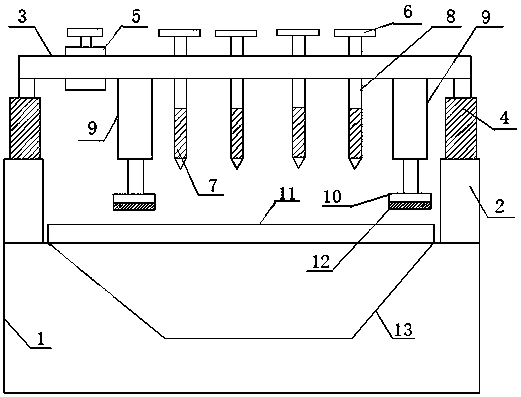

[0014] Such as figure 1 A kind of plank punching device shown comprises workbench 1, support frame 2, cross bar 3, hydraulic cylinder 4, motor 5, transmission wheel 6, drill rod 7, and described support frame 2 is arranged on the two sides of workbench 1 On the side, two support frames 2 on both sides of the workbench 1 are respectively provided with a hydraulic cylinder 4, and the piston rods of the two hydraulic cylinders 4 are connected by a cross bar 3, and the cross bar 3 is provided with a motor 5 and a plurality of transmissions. Wheel 6, motor 5 is connected with transmission wheel 6 through belt, and the center of described transmission wheel 6 is provided with the transmission rod 8 that is connected with drilling rod 7, and the end of transmission rod 8 is provided with the internal thread that is opposite to transmission wheel 6, T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com