A pin connection structure

A connection structure and pin shaft technology, which is applied in the direction of connection components, mechanical equipment, etc., can solve the problems of easy wear and tear, shearing or falling off, low installation efficiency, and weak structural stability of cotter pins, etc., to achieve limited wear or shearing, and high installation efficiency , The connection is safe and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

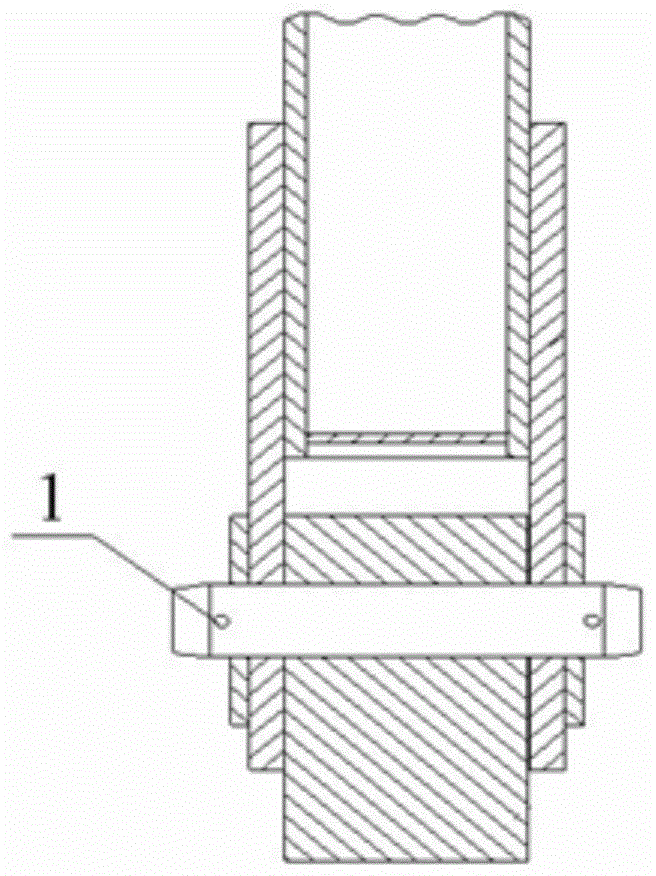

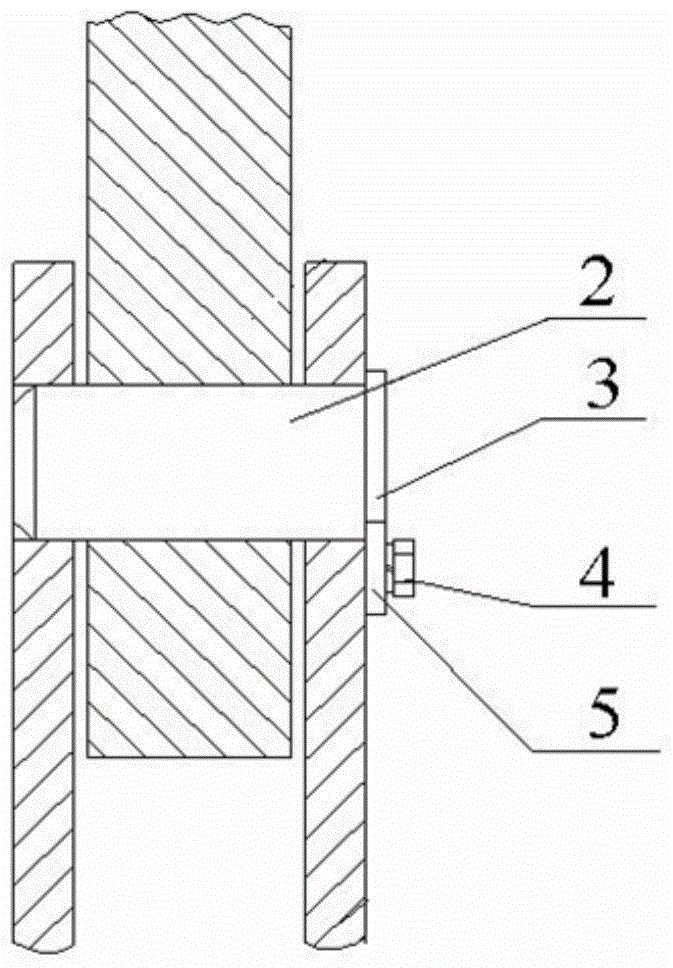

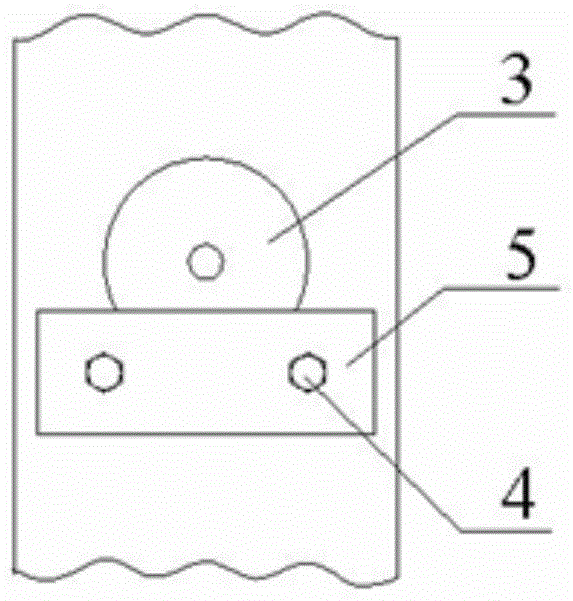

[0021] like Figure 4 and Figure 5 As shown, a pin connection structure, including a headless pin 1 that can be installed in the connector, pin holes are opened at both ends of the headless pin 1, and also includes a The stop sleeve 8 is limited in the axial direction of the pin shaft. The stop sleeve 8 is connected with the headless pin shaft 1 through the vertical pin 12. One end of the vertical pin 12 has a pin hole, and the hole end of the vertical pin 12 is equipped with a lock for fixing. live in institutions.

[0022] The stop sleeve 8 is set on the shaft end of the headless pin shaft 1, and the stop sleeve 8 has a mounting hole for installing the vertical pin 12, and the vertical pin 12 passes through the installation hole on the stop sleeve 8 and the pin shaft on the headless pin shaft 1 Fix the stop sleeve 8 on the headless pin shaft 1 after the hole, install ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com