Organic super capacitor with low internal resistance

A supercapacitor, low internal resistance technology, applied in the direction of capacitors, electrolytic capacitors, capacitor parts, etc., can solve the problems of increased resistance, large internal resistance, etc., and achieve the effect of simple structure, low internal resistance of products, and convenient manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

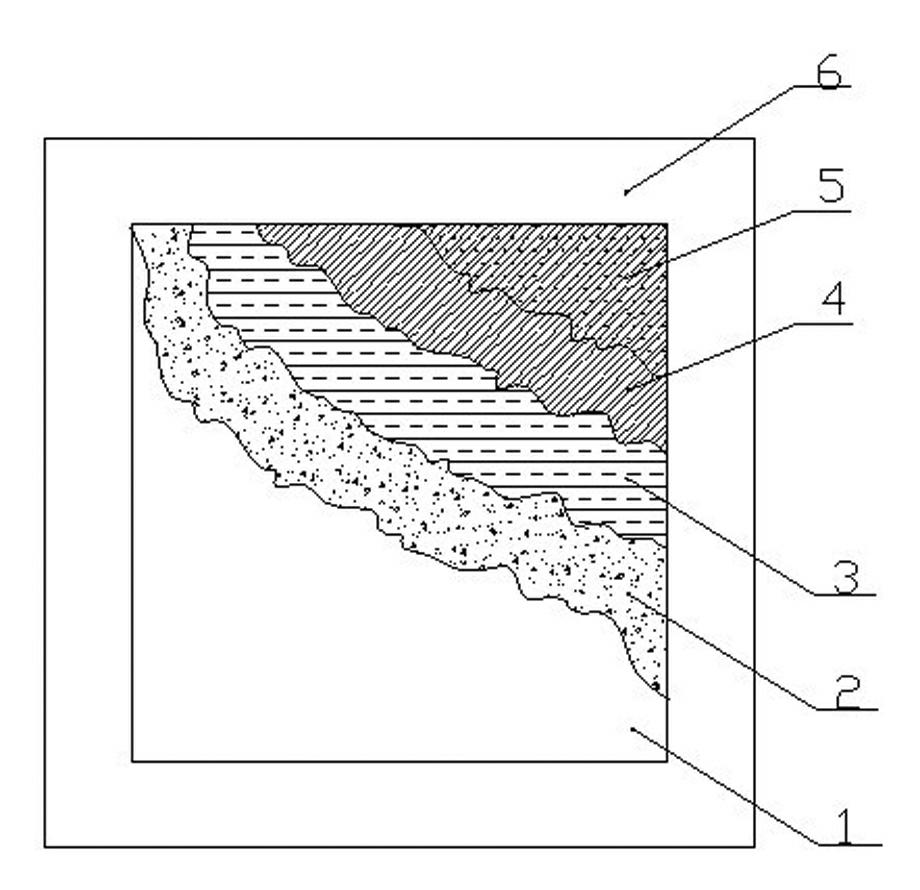

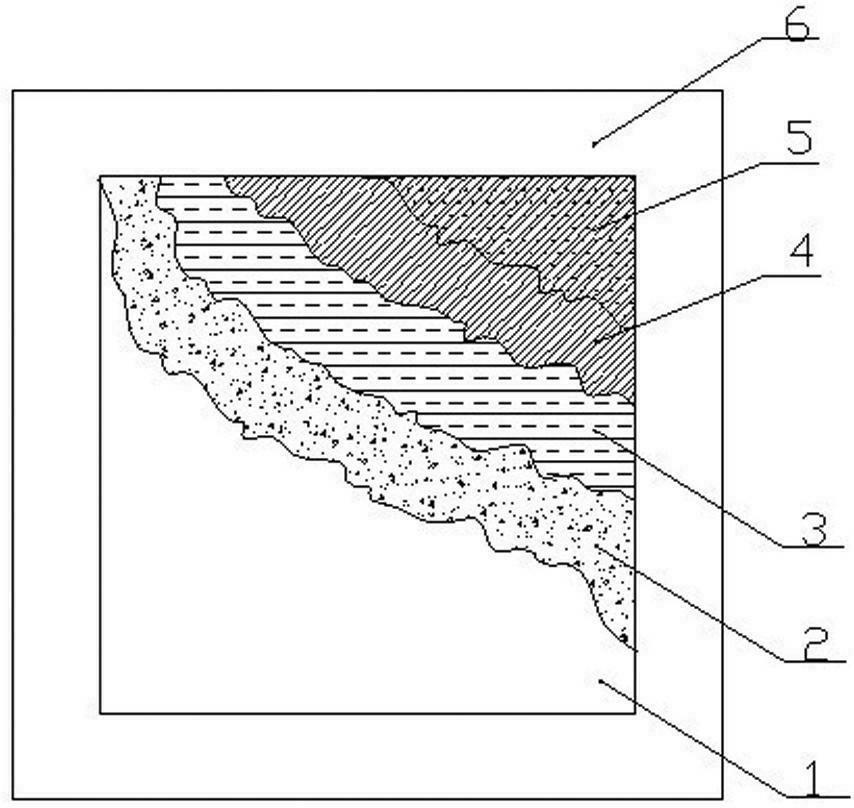

[0016] As shown in the figure, the output structure of the low internal resistance organic supercapacitor includes positive electrode 2, negative electrode 4, separator 3, aluminum-plastic film 6 and other parts. The positive and negative electrodes 2 and 4 are made of aluminum foil collectors and coated on the collectors. active substance composition. The positive and negative electrodes of the supercapacitor adopt a planar output structure. The positive output surface 1 and the negative output surface 5 are respectively on the upper and lower sides of the supercapacitor. planes in close contact.

[0017] The active material slurry is evenly coated on the corroded aluminum foil current collector according to the conventional method, and after drying, it is cut into corresponding size pole pieces as the positive electrode 2 and the negative electrode 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com